Solid adsorption moisture eliminator based on semiconductor refrigeration

A solid adsorption and semiconductor technology, which is applied in refrigerators, refrigeration and liquefaction, and machines using electric/magnetic effects, etc., can solve the problem of rising regeneration temperature of solid adsorbents, difficulty in dehumidification process, internal cooling, internal heating and constraints in regeneration process Problems such as the dehumidification capacity of solid adsorbents, to achieve the effect of reducing requirements, improving performance, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

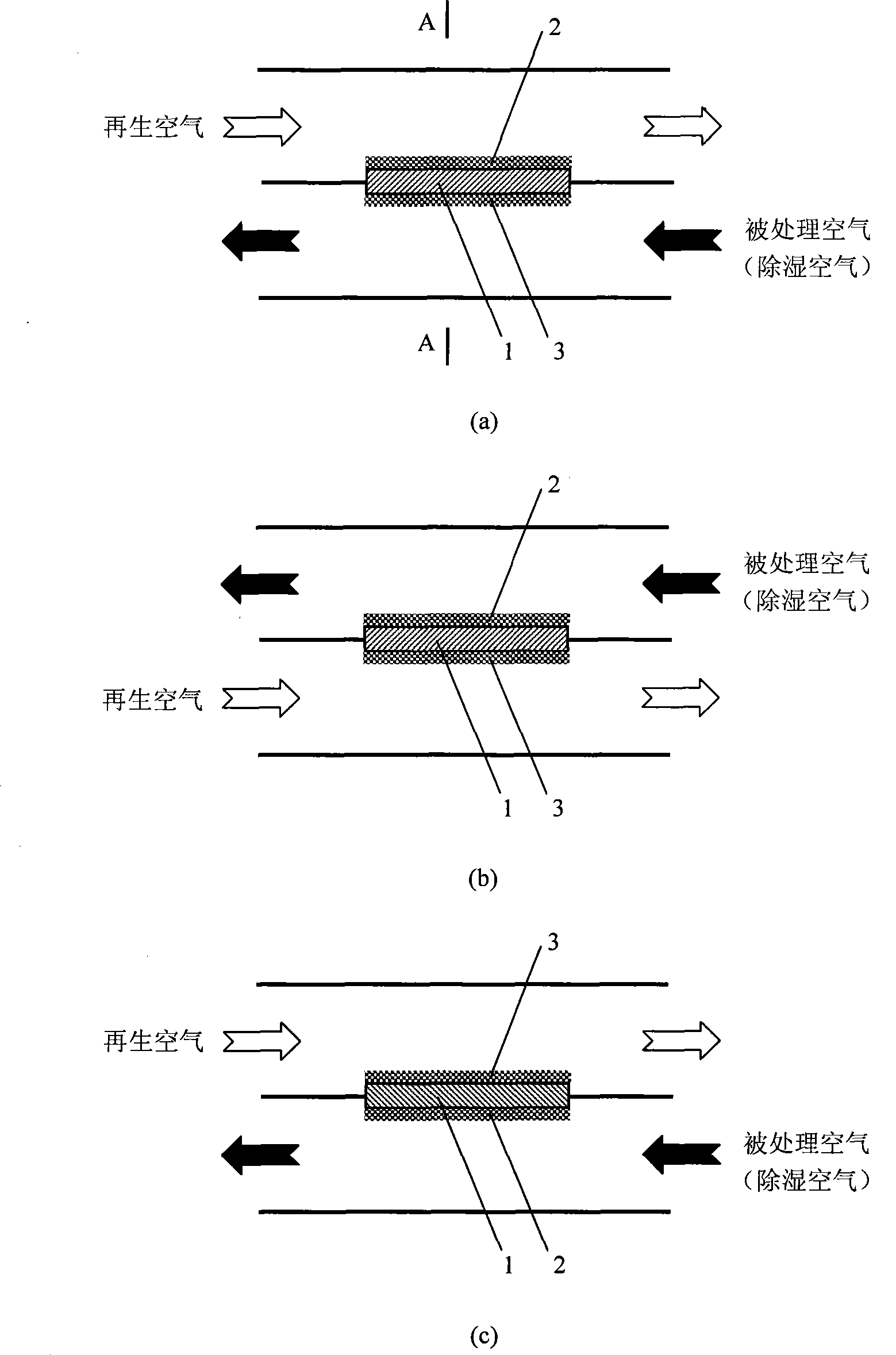

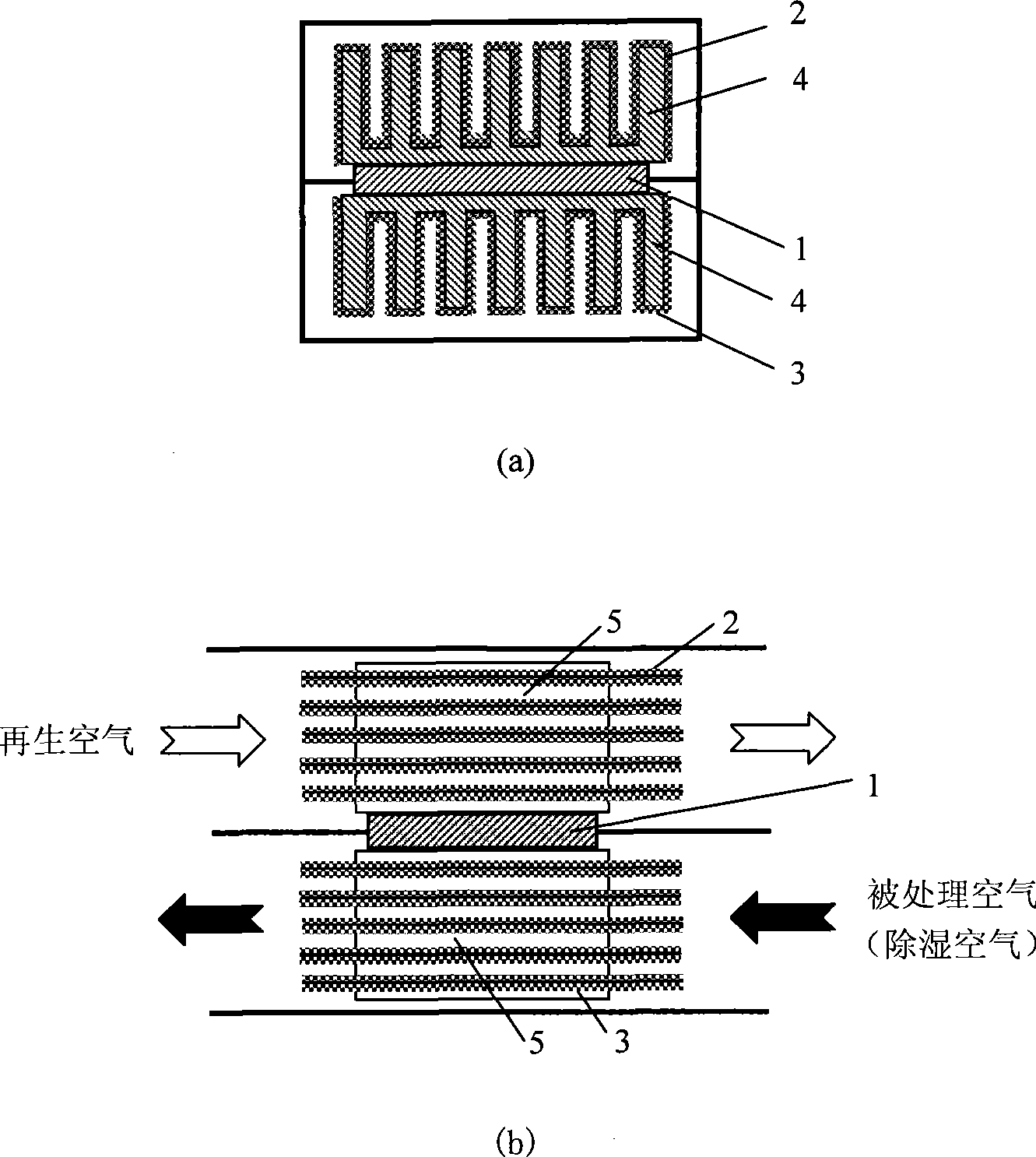

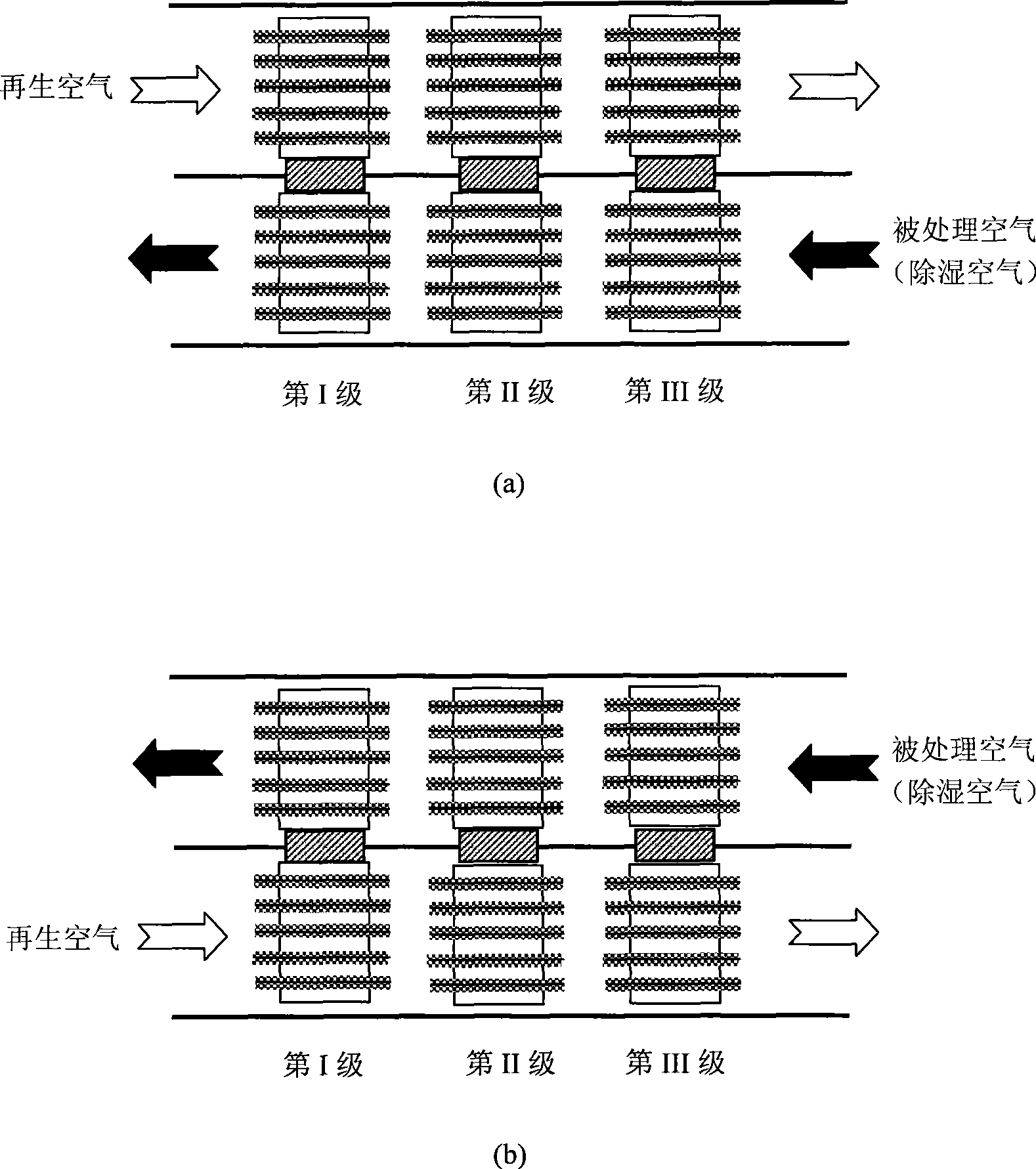

[0013] The main feature of the invention is the organic combination of semiconductor refrigeration mode and solid adsorption dehumidification mode. The solid hygroscopic agent is respectively placed at the cold end and the hot end of the semiconductor refrigeration device. The treated air flows through the cold end and directly contacts with the solid moisture absorbent to realize the heat and mass transfer process. The humidity and temperature of the treated air are reduced, and it is directly sent into the room. The regeneration air (which can be indoor exhaust air) flows through the hot end of the semiconductor refrigeration, directly contacts the solid moisture absorbent, and takes away the moisture in the moisture absorbent, thereby realizing the regeneration process of the solid moisture absorbent. After half a cycle, change the direction of the current in the semiconductor, and at the same time rotate the semiconductor refrigeration sheet or use the air valve to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com