Binary medium solar high temperature heat absorption/storage device

A solar energy and heat accumulator technology, applied in the field of solar high temperature heat absorption/heat accumulator, can solve the problems of lower heat exchange efficiency, less heat storage capacity, less heat storage working medium, etc., so as to improve heat exchange efficiency and reduce occupied space , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

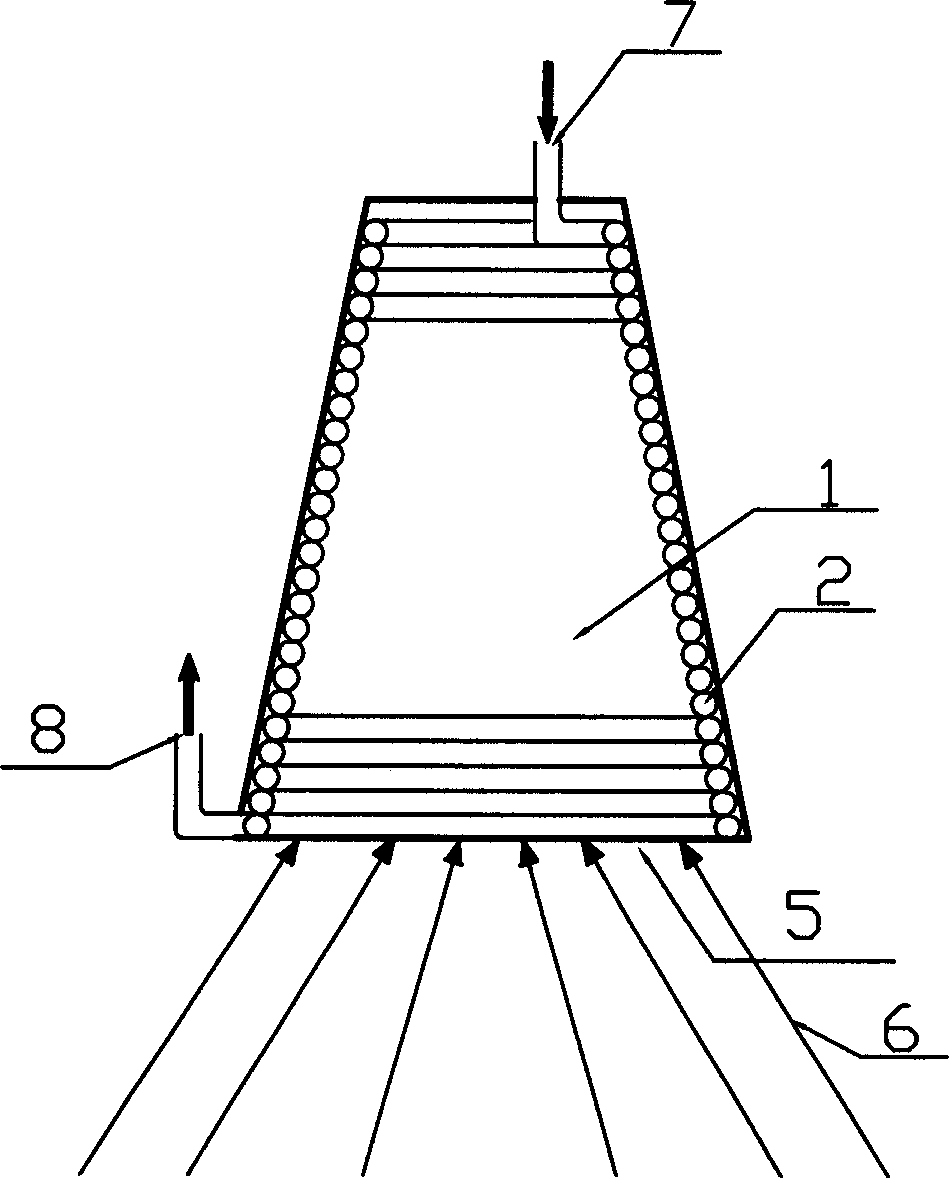

[0017] For this example, see the attached figure 1 , figure 1 It is a schematic diagram of a heat absorber / regenerator having a frustum-shaped shape and a coil heat exchanger arranged in a spiral arrangement as the heat exchanger 2 . The frustoconical shape conforms to the energy density distribution of the light spot of the concentrator, which can absorb the heat efficiently; the spiral arrangement of the coil heat exchanger 2 increases the length of the tube, increases the heat exchange area, and improves the heat exchange efficiency. The heat absorber / regenerator absorbs the heat of the incident light 6 from the heat absorbing surface 5 coated with a high-quality heat absorbing coating, and transmits it to the heat storage working medium 1, and the heat storage working medium 1 changes from solid to liquid, which is a phase change heat storage ; wherein the regenerative working medium 1 is a molten salt with a melting point above 400° C. for high-temperature phase transiti...

Embodiment 2

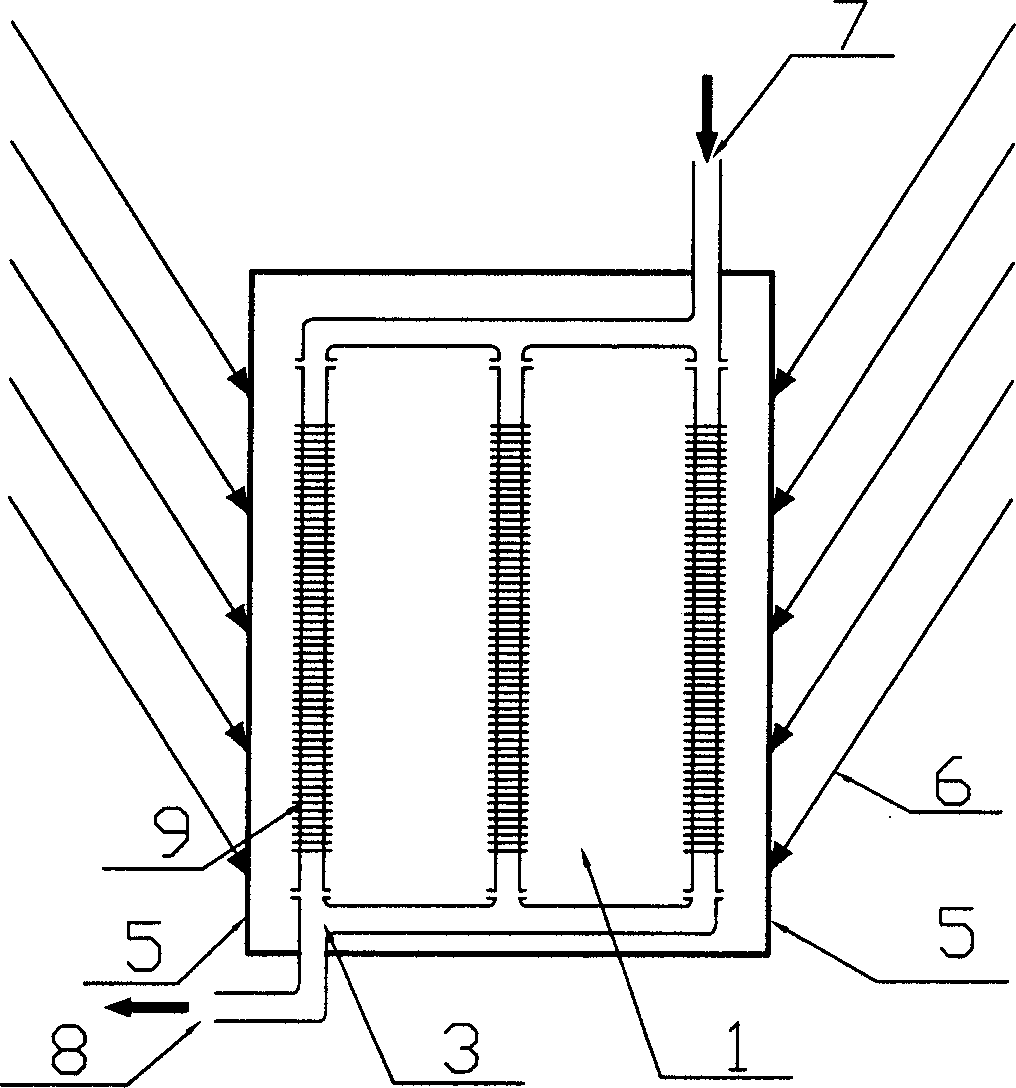

[0019] For this example, see the attached figure 2 , figure 2 It is a schematic diagram of a ribbed heat pipe heat exchanger 3 in which the heat absorber / regenerator has a cylindrical shape and the heat exchanger is a ribbed sheet 9 . The cylindrical process is simple and cost-saving; when the heat exchanger is finned, the heat exchange area is increased and the heat exchange efficiency is improved. The heat absorber / regenerator absorbs the heat of the incident light 6 from the heat absorbing surface 5 coated with a high-quality heat absorbing coating, and transmits it to the heat storage working medium 1, and the heat storage working medium 1 changes from solid to liquid, which is a phase change heat storage ; wherein the regenerative working medium 1 is a molten salt with a melting point above 400° C. for high-temperature phase transition; at the same time, the regenerative working medium 1 heats the circulating working medium flowing in from the inlet 7, and the circulat...

Embodiment 3

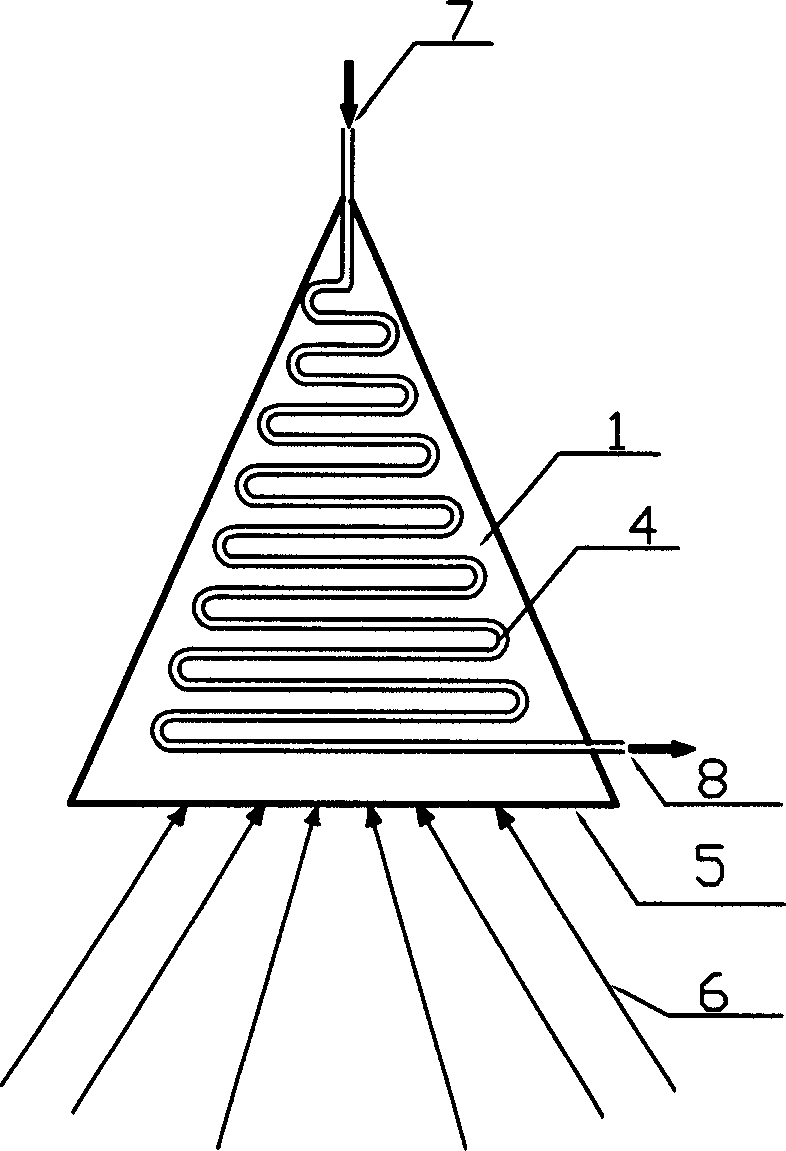

[0021] For this example, see the attached image 3 , image 3 It is a schematic diagram of the heat absorber / regenerator having a conical shape and the heat exchanger being a U-shaped tube heat exchanger 4 . The conical shape is similar to the light spot energy density distribution of the concentrator, and the process is simple, which saves cost; the heat exchanger is a U-shaped tube, which is convenient to manufacture, simple process, and saves cost. The heat absorber / regenerator absorbs the heat of the incident light 6 from the heat absorbing surface 5 coated with a high-quality heat absorbing coating, and transmits it to the heat storage working medium 1, and the heat storage working medium 1 changes from solid to liquid, which is a phase change heat storage wherein the regenerative working medium 1 is a molten salt with a melting point above 400° C. for phase transition at a high temperature; at the same time, the regenerative working medium 1 heats the circulating workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com