Oil and smoke purifier of low-temperature plasma synergistic modified filtering membrane

A low-temperature plasma and oil fume purifier technology, which is applied in the fields of filtration and separation, oil fume removal, chemical instruments and methods, etc., can solve the problems of concentration drop, the purification effect of high concentration oil fume needs to be further improved, etc., and achieves reduced pressure drop and simple structure. , to avoid the effect of electrode corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

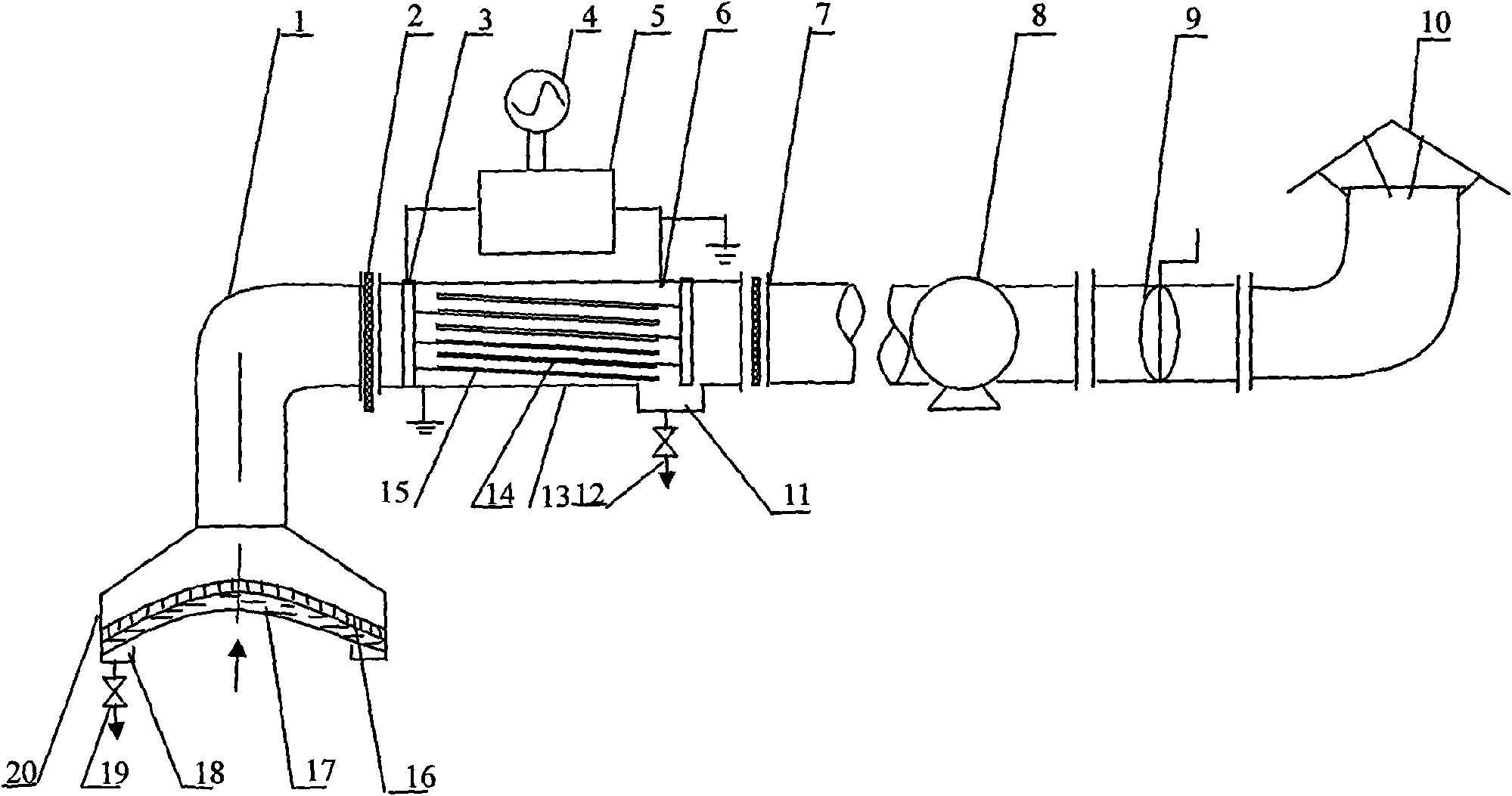

[0025] see figure 1 , Low-temperature plasma combined with surface modification filter membrane to purify cooking oil fume purifier includes gas collection hood 20, the top of gas collection hood 20 is connected to exhaust pipe through elbow 1, and rainproof cap 10 is installed at the outlet of exhaust pipe.

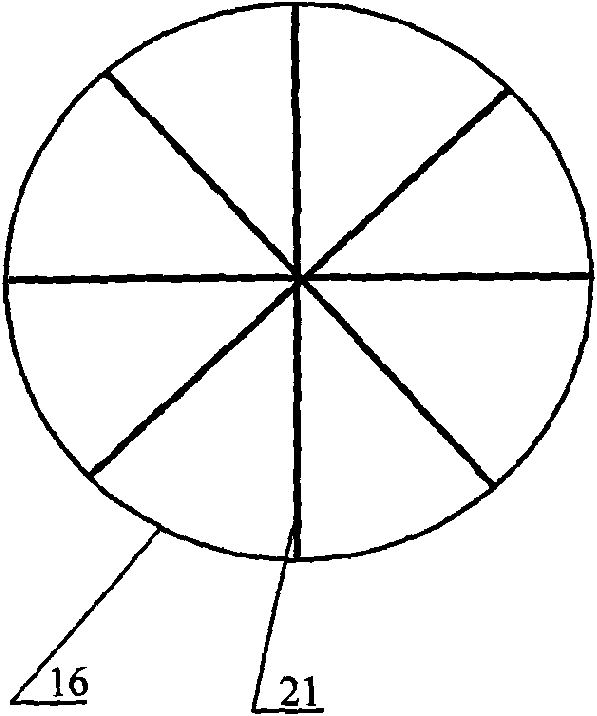

[0026] A stainless steel mesh 16 is installed on the working surface of the gas collecting hood 20, and the stainless steel mesh 16 is provided with a filter membrane 17, and the lower edge of the gas collecting hood 20 is inwardly folded to form a first-stage oil collecting tank case 18. The stainless steel net 16 is a radial net, and the inner surface of the net is equipped with a "rice" font stainless steel bar 21, see figure 2 This stainless steel mesh can both play a reinforcement effect, and can be used as the diversion mechanism of intercepting oil dirt again, the liquid oil dirt that makes filter membrane 17 surface intercepts can flow in the oil sump box 18 of ...

Embodiment 2

[0032] A pair of anode plates 15 and cathode plates 14 which are staggered and parallel to each other are installed in the secondary oil collection tank 13, and the material of the anode plates is aluminum.

[0033] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com