Multi-window multifunctional gas and dust explosion inhibition experiment system

A dust explosion and experimental system technology, applied in the direction of material explosiveness, etc., can solve the problems of small observation window size, low light transmittance, and inability to realize multiple gas preparation, and achieve the effect of increasing the visualization range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

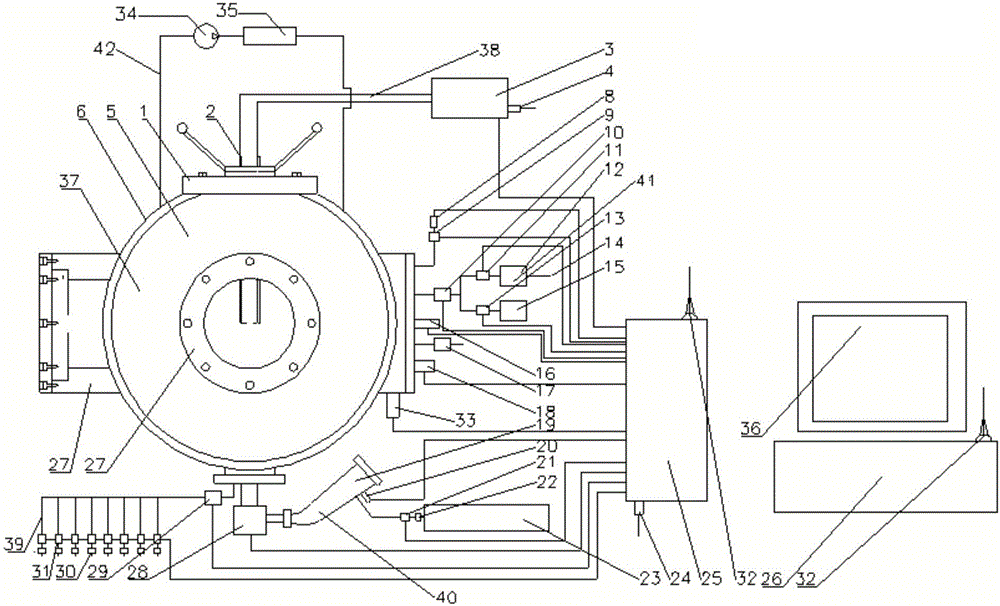

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] A multi-window multifunctional gas and dust explosion suppression experiment system such as figure 1 As shown, the explosion vessel 37 includes a volume of about 20L, an explosion reaction tank body 5 with an inner diameter of about 340mm and a reaction tank cover 1 fastened on the top of the explosion reaction tank body 5 by a flange, and the explosion vessel 37 extends three diameters of 110mm, optical diagnostic window 27 with light transmittance not less than 90%, one pair is set on the parallel line at the central horizontal position, and the other is set at the same horizontal position perpendicular to the direction of the parallel line, which is convenient for installing optical testing equipment and Ensure that the window glass is not polluted after powder spraying in the container.

[0024] The heating constant tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com