Gas-phase high pressure pulse discharge device and method for catalytically degrading organic dyes in water by same

A high-voltage pulse discharge and catalytic degradation technology, applied in electrochemical water/sewage treatment, oxidized water/sewage treatment, adsorbed water/sewage treatment, etc. Unable to adjust and limit the gas phase discharge efficiency, etc., to achieve the effect of improving contact, increasing processing capacity, and increasing reaction probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

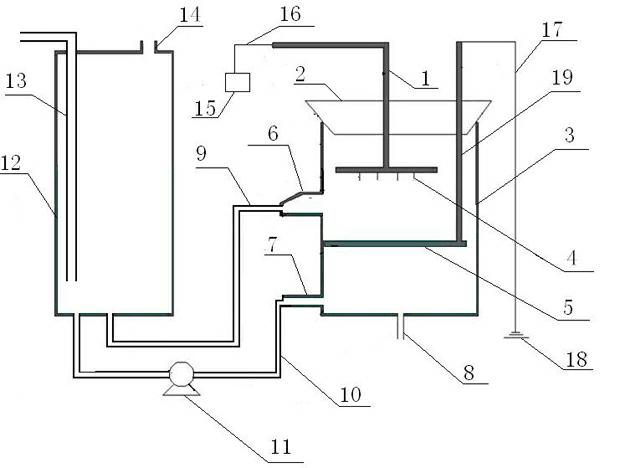

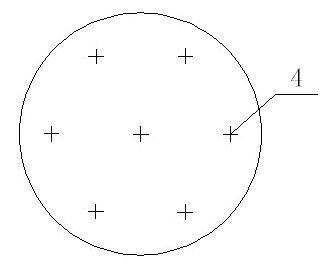

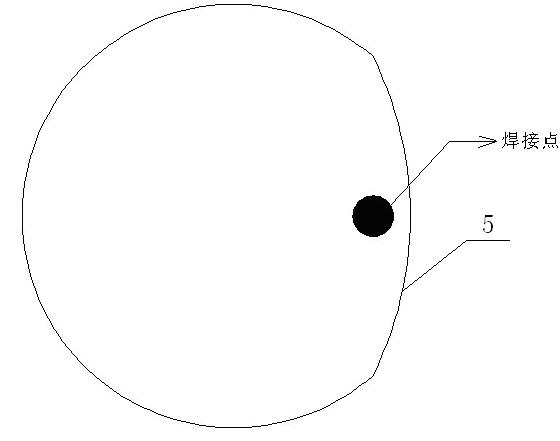

[0026] Embodiment 1: refer to figure 1 , 2 and 3, the device comprises a cylindrical reactor 3 and its bottom air inlet pipe 8, a liquid storage tank 12 and its top air outlet 14, a high-voltage electrode 4 suspended on the upper part of the reactor by fixing guide rods 1, 19 and the lower part The ground electrode 5, the external high-voltage pulse power supply 15; the top opening of the reactor is blocked with a rubber plug 2, and the opening 6 on the side wall of the reactor is connected to the liquid storage tank 12 through the liquid return pipe (liquid outlet pipe) 9, and the open The hole 6 is located between the high-voltage electrode 4 and the ground electrode 5. The opening 7 in the lower part of the side wall of the reactor is connected to the liquid storage tank 12 through the liquid inlet pipe 10, and a peristaltic pump 11 is arranged on the liquid inlet pipe; the high-voltage electrode 4 passes through the wire 16 is connected with the high-voltage pulse power s...

Embodiment 2

[0027] Embodiment 2: This device is on the basis of embodiment 1, also comprises: the material of reactor 3 is plexiglass, and internal diameter is 65mm; The diameter of the needle is 0.25mm, the distance between the needles is 15mm, and the height of the needle is 4mm. The distance between the electrode and the liquid surface is 10-30mm; the liquid storage tank 12 is provided with a sampling tube 13 extending from the top to the bottom; the reaction device is powered by a high-voltage pulse power supply 15 with a peak voltage of 46KV and a frequency of 80Hz.

Embodiment 3

[0028] Embodiment 3: refer to figure 1 , 2, 3 and 4, the method that utilizes the vapor phase high-voltage pulse discharge device of the device described in embodiment 2 to catalyze the degradation of organic dyes in water: the activated carbon fiber with a thickness of 3mm is put into a carbonization activation furnace and activated with water vapor to expand its aperture to carry out Pore structure adjustment of activated carbon. During the activation process, nitrogen gas is introduced as a protective gas. When the temperature rises to 800°C, water vapor is activated for 100 minutes. The purpose of activation is to increase the specific surface area of activated carbon fibers to greater than 1000m 2 / g (correspondingly increase the ratio of the pore diameter above 2nm), so that it can effectively absorb macromolecular organic matter in water while absorbing dissolved ozone in water, and react on the surface of carbon. Add 3g of activated carbon fiber into the reactor,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com