Diesel particle filter regenerating unit and control method thereof

A particle trap and regeneration device technology, which is applied to the electric control of the exhaust treatment device, the silencer device, the exhaust device, etc., can solve the problems of difficult disassembly, trap ablation, and filter body cracking, etc. Achieve the effect of saving precious metals, realizing energy saving and environmental protection, and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

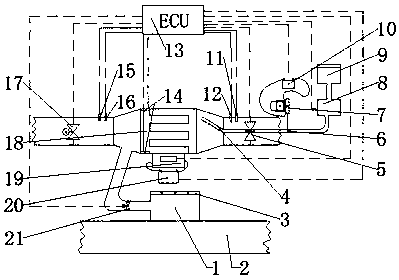

[0025] Embodiment 1: as figure 1 As shown, a particle trap regeneration device includes a water inlet pipe, a particle trap 18, a sewage tank 1, a regeneration electronic control unit ECU13, and an engine exhaust pipe 2. The particle trap 18 includes sequentially connected Upstream pipeline (exhaust gas inflow end), inner cavity and downstream pipeline (exhaust gas outflow end), rotating bearing 6 is arranged in the middle of the water inlet pipe, the front end of the water inlet pipe is connected with the high-pressure pulse rotary recoil nozzle 4, and the rear end is connected with clean water through the high-pressure pump 8 The box 9 is connected; the rotating bearing 6 is driven to rotate by the rotating motor 7, and the power supply I10 supplies power to the rotating motor 7; an upstream solenoid valve 17 is installed in the upstream pipeline of the particle trap 18, and an upstream pressure sensor is installed on the upper end of the upstream pipeline 15. The upstream tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com