Method for detecting anti-seepage effect of anti-seepage film

A detection method and anti-seepage film technology, which is applied in the application of electric devices to test fluid tightness, etc., can solve the problems of anti-seepage film damage and leak location difficult to detect, and achieve the goal of avoiding blindness, high detection accuracy, and simple measurement process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

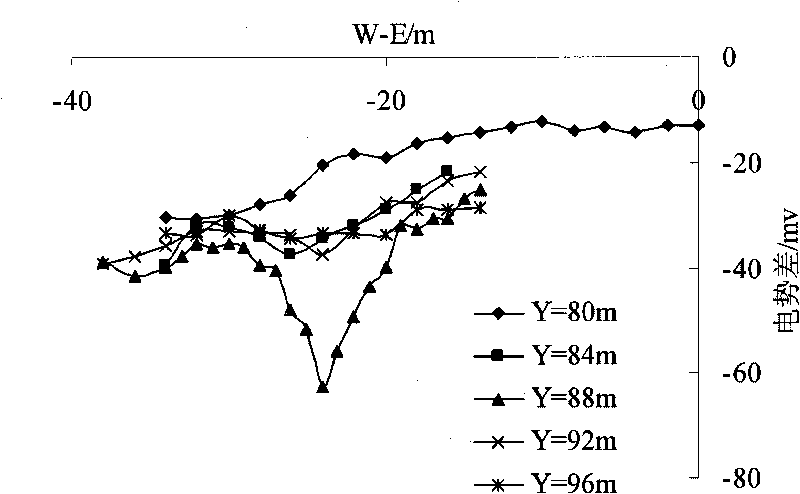

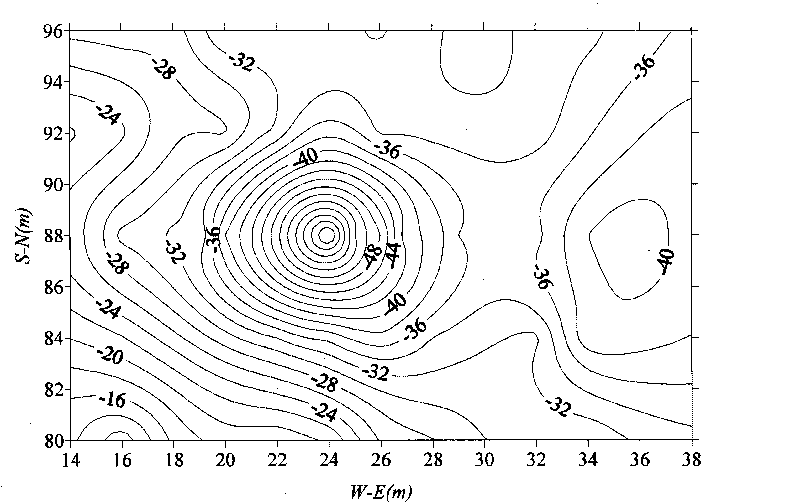

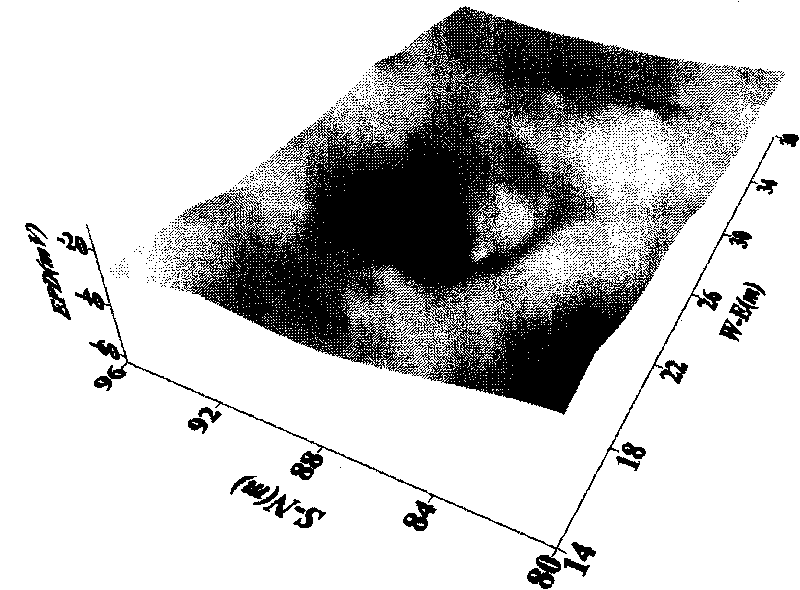

[0023] In view of the electrical insulation of the anti-seepage membrane, when the membrane is intact, there is no or only a small amount of current in the power supply circuit, and the potential difference in the entire area is evenly distributed; when there is a leak in the anti-seepage membrane, the insulation of the membrane is damaged, there will be The current passes through the hole, distorting the potential difference distribution there.

[0024] According to the above principles, the present invention is based on Figure 5 The shown method flow has designed the following implementation steps:

[0025] (1) In order to ensure the measurement effect, cover the upper part of the anti-seepage membrane with a water-retaining layer that keeps moist, such as wet sand, to ensure good conductivity above the membrane;

[0026] (2) One power supply electrode is respectively fixed on the upper and lower sides (in the soil) of the anti-seepage membrane. In the embodiment, the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com