High-voltage pulse resistance voltage divider

A resistive voltage divider and high-voltage pulse technology, applied in the field of performance devices, can solve the problems of increasing the overall lateral size of the voltage divider, and achieve the effects of simple and easy structure and reduction of step response time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

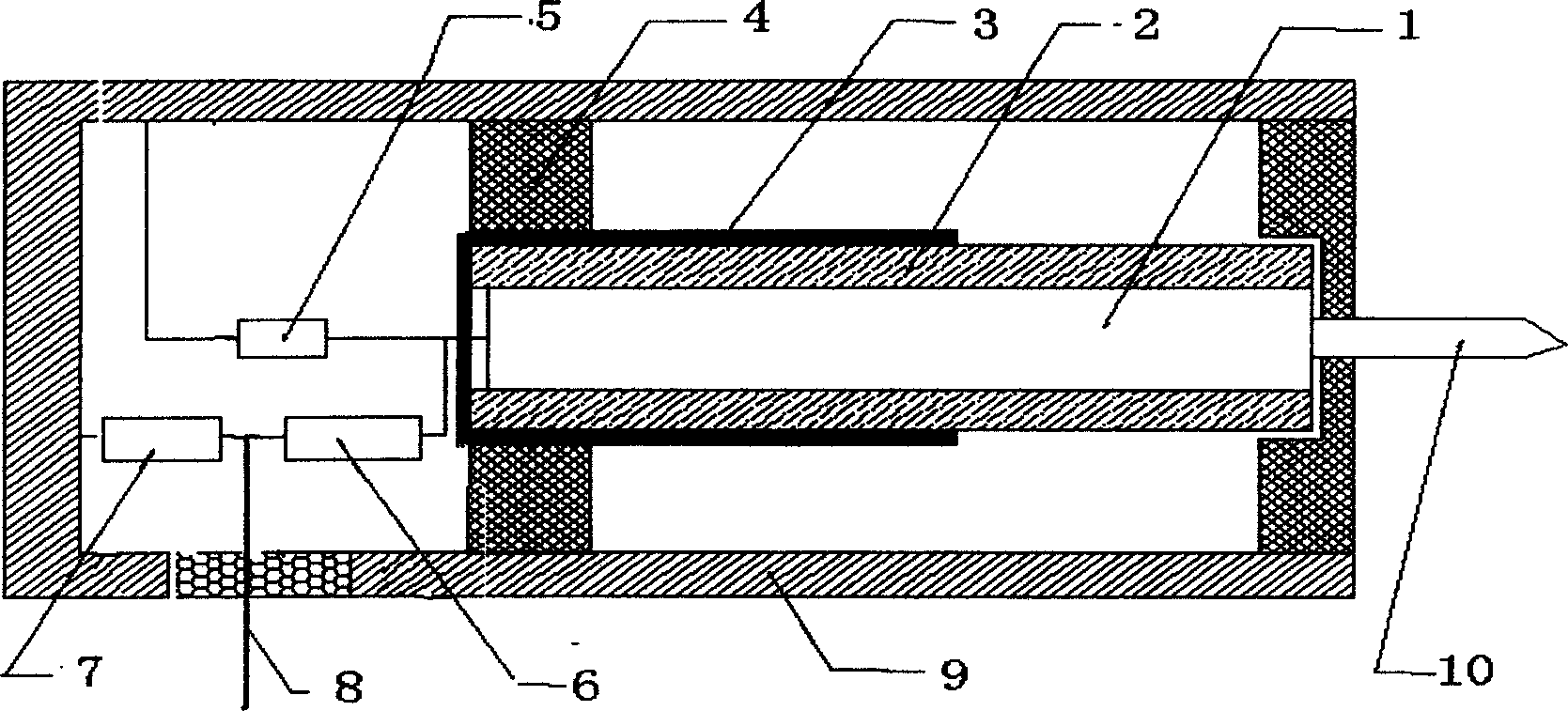

[0013] The outer layer shield 9 of the high-voltage pulse resistance voltage divider of the present invention is a hollow tube, and the first-stage high-voltage arm resistor 1 is arranged in the outer layer shield 9, and an insulating sleeve is set outside the first-stage high-voltage arm resistor 1 The tube 2 is covered with a sleeve electrode 3 at one end of the insulating sleeve 2, and the two ends of the insulating sleeve 2 are respectively supported by the high-voltage arm bracket 4 in the outer shielding cover 9, and connected to the outer end of the first-stage high-voltage arm resistance 1 There is a high-voltage input pole 10, the inner end of the first-stage high-voltage arm resistor 1 is connected to the sleeve electrode 3, and a first-stage low-voltage arm resistor 5 and a second-stage high-voltage arm resistor 5 are arranged between the bottom of the outer shield 9 and the high-voltage arm bracket 4. Arm resistance 6, second-stage low-voltage arm resistance 7, volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com