Preparation method of chitosan/sodium polyphosphate porous microcarrier

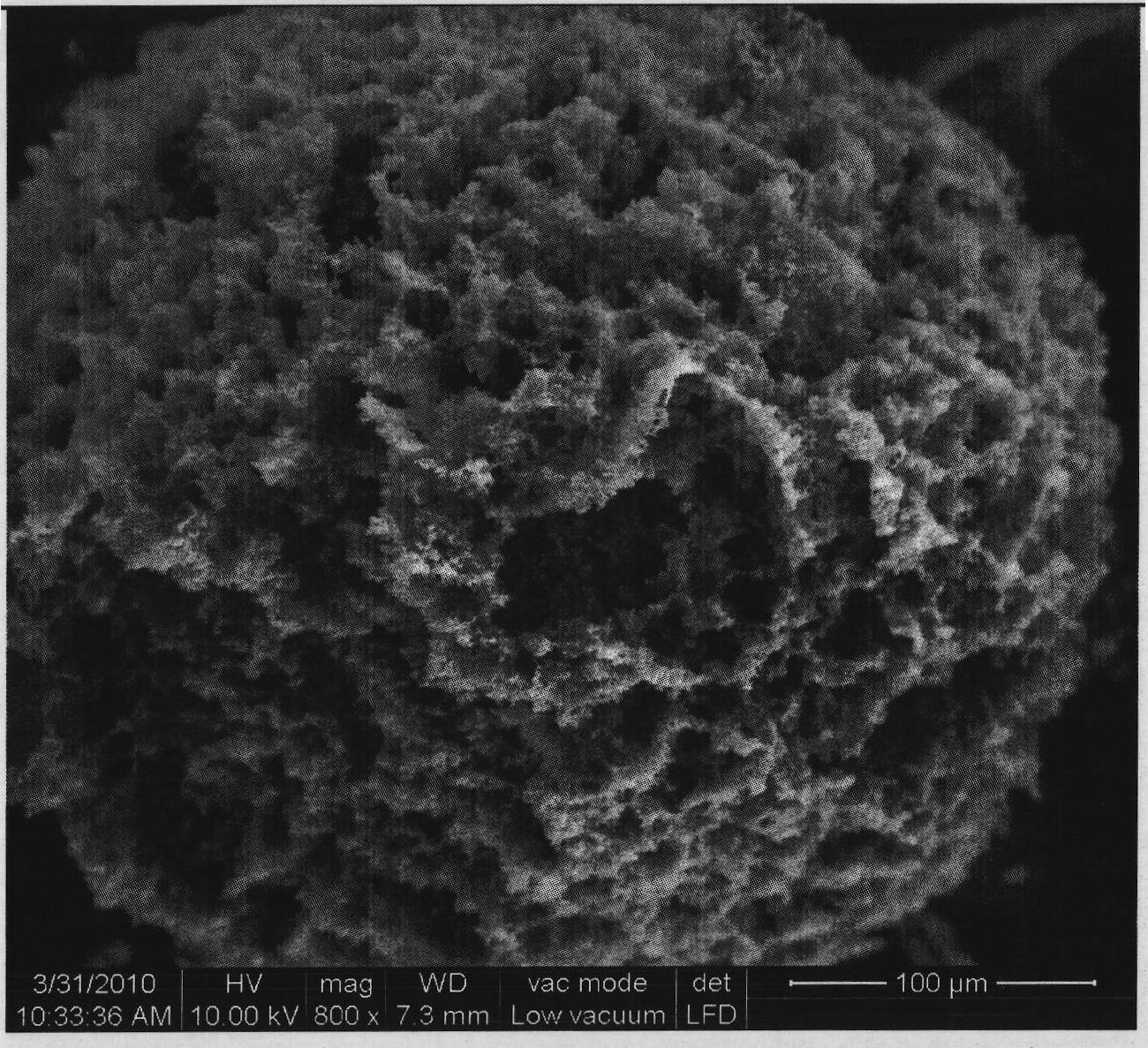

A technology of sodium polyphosphate and chitosan acid, which is applied in the preparation of microspheres, microcapsule preparations, animal cells, etc., can solve problems such as unevenness, poor controllability, and uncontrollable particle size, and achieve roundness The effect of high density and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

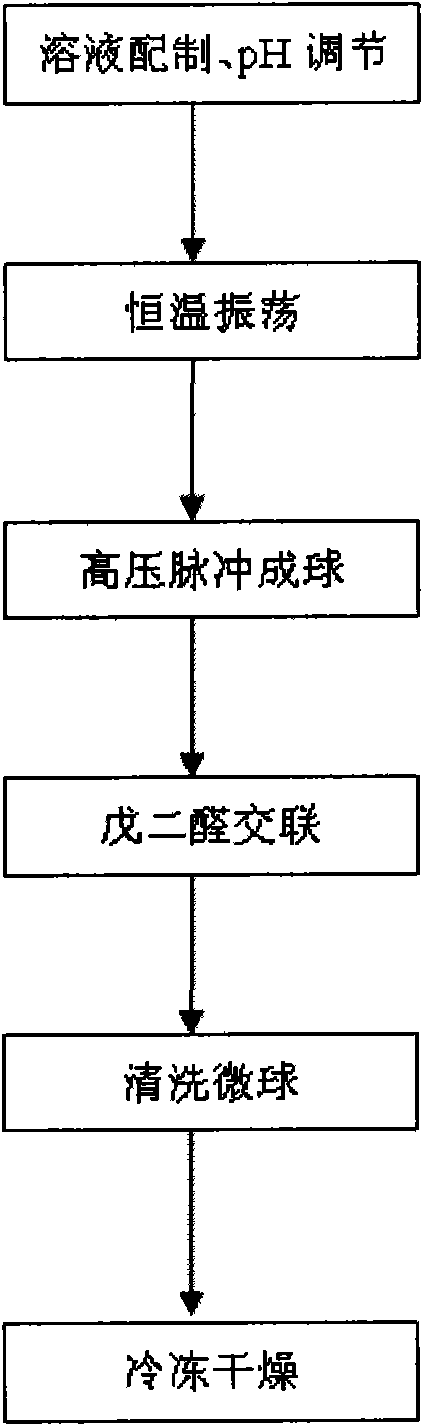

[0035] A kind of preparation method of chitosan / sodium polyphosphate porous micro-carrier high-pressure pulse into balls, comprising the following steps:

[0036] (1), solution preparation

[0037] Preparation concentration is 2.5% chitosan acid solution and pH is 10 sodium polyphosphate aqueous solution;

[0038] Wherein the reaction ratio of chitosan acid solution and sodium polyphosphate aqueous solution is calculated by volume, i.e. chitosan acid solution: sodium polyphosphate aqueous solution is 2: 1;

[0039] The chitosan deacetylation degree ≥ 90%;

[0040] (2), constant temperature oscillation

[0041] Oscillate the 2.5% chitosan acid solution obtained in step (1) in a constant temperature oscillator, control the temperature of the water bath at 37° C., and leave it to defoam after 24 hours of constant temperature;

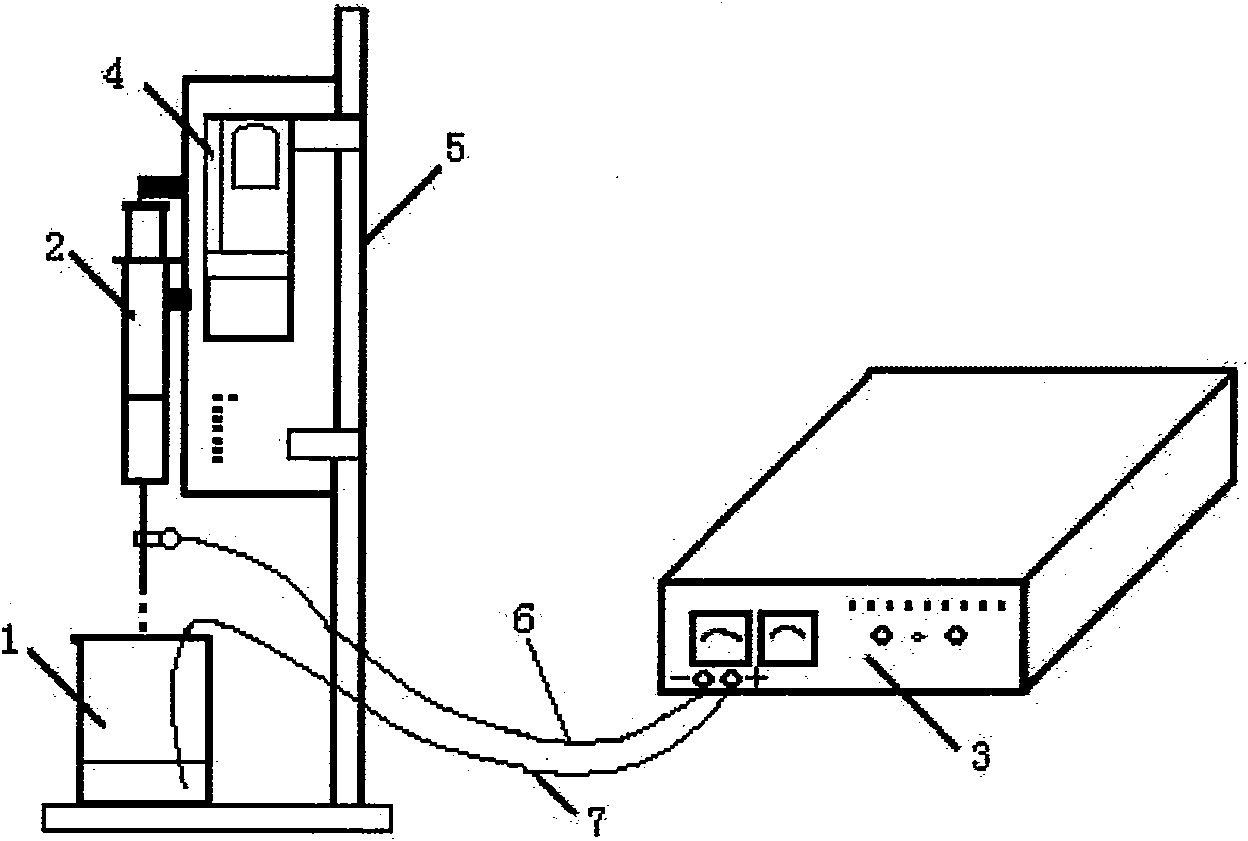

[0042] (3), high-voltage pulse into a ball

[0043] Step (2) After constant temperature oscillation and defoaming, the concentration is 2.5% chitosan ...

Embodiment 2

[0054] A kind of preparation method of chitosan / sodium polyphosphate porous micro-carrier high-pressure pulse into balls, comprising the following steps:

[0055] (1), solution preparation

[0056] Preparation concentration is 2% chitosan acid solution and pH is 10 sodium polyphosphate aqueous solution;

[0057] Wherein the reaction ratio of chitosan acid solution and sodium polyphosphate aqueous solution is calculated by volume, i.e. chitosan acid solution: sodium polyphosphate aqueous solution is 2: 1;

[0058] The chitosan deacetylation degree ≥ 90%;

[0059] (2), constant temperature oscillation

[0060] Oscillate the 2% chitosan acid solution obtained in step (1) in a constant temperature oscillator, control the temperature of the water bath at 37° C., and leave it to defoam after 24 hours of constant temperature;

[0061] (3), high-voltage pulse into a ball

[0062] Step (2) After constant temperature oscillation and defoaming, the concentration is 2% chitosan acid sol...

Embodiment 3

[0072] A kind of preparation method of chitosan / sodium polyphosphate porous micro-carrier high-pressure pulse into balls, comprising the following steps:

[0073] (1), solution preparation

[0074] Preparation concentration is 3% chitosan acid solution and pH is 10 sodium polyphosphate aqueous solution;

[0075] Wherein the reaction ratio of chitosan acid solution and sodium polyphosphate aqueous solution is calculated by volume, i.e. chitosan acid solution: sodium polyphosphate aqueous solution is 2: 1;

[0076] The chitosan deacetylation degree ≥ 90%;

[0077] (2), constant temperature oscillation

[0078] Vibrate the 3% chitosan acid solution obtained in step (1) in a constant temperature oscillator, control the temperature of the water bath at 37° C., and leave it to defoam after 24 hours of constant temperature;

[0079] (3), high-voltage pulse into a ball

[0080] Step (2) After constant temperature oscillation and defoaming, the concentration is 3% chitosan acid sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com