Method for preparing Inconel 625 alloy spherical powder

A spherical powder and alloy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of production difficulty and procurement cost increase, and achieve the effect of improving powder yield, easy large-scale repetitive production, and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

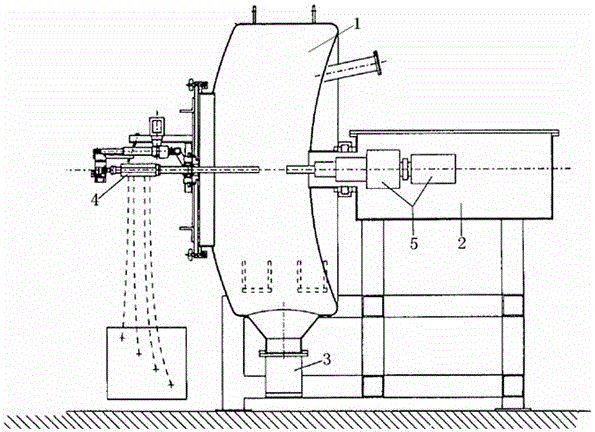

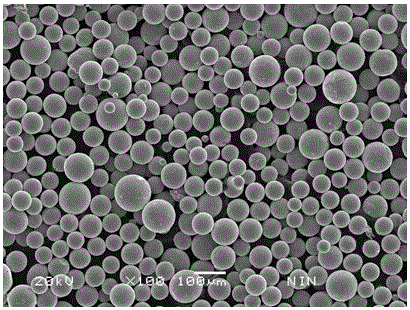

[0029] Embodiment 1: the preparation of Inconel625 alloy spherical powder

[0030] The mass ratio of the main elements is Ni-21Cr-8.5Mo-3.5Nb-4Fe, and the mass percentage of trace elements does not exceed the standard value, that is, C is not more than 0.1%, Al is not more than 0.4%, Ti is not more than 0.04%, Co Not more than 1%, Mn not more than 0.5%, S not more than 0.015%, P not more than 0.015%, Si not more than 0.5%, Ta not more than 0.05%, wherein the Nb element comes from the NbFe alloy containing Nb70%. Carry out a smelting in a vacuum induction furnace with a vacuum degree of 0.1Pa; remove the surface scale of the first smelting, and perform a second vacuum self-consumption remelting with a vacuum degree of 0.05Pa to obtain a second smelting of Inconel625 master alloy with a relative density of 87%. Ingot-shaped billet; master alloy rods with a density of 99.6% are obtained by isothermal free forging, and are machined into Inconel625 alloy electrode rods with a diame...

Embodiment 2

[0032] Embodiment 2: the preparation of Inconel625 alloy spherical powder

[0033] The mass ratio of the main elements is Ni-22.5Cr-9.5Mo-4Nb-2Fe, and the mass percentage of trace elements does not exceed the standard value, that is, C is not more than 0.1%, Al is not more than 0.4%, Ti is not more than 0.04%, Co Not more than 1%, Mn not more than 0.5%, S not more than 0.015%, P not more than 0.015%, Si not more than 0.5%, Ta not more than 0.05%, wherein the Nb element comes from the NbFe alloy containing Nb70%. Carry out a smelting in a vacuum induction furnace with a vacuum degree of 0.05Pa; remove the surface oxide skin of the first smelting, and perform a second vacuum self-consumption remelting with a vacuum degree of 0.01Pa to obtain a second smelting of Inconel625 master alloy with a relative density of 88%. Ingot billet. A master alloy rod with a density of 99.5% was obtained by isothermal free forging, and processed into an Inconel625 alloy electrode rod with a diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com