Method for preparing Ti-6Al-7Nb medical titanium alloy spherical powder

A technology of ti-6al-7nb and spherical powder, which is applied in the field of metal and alloy powder preparation, can solve the problem of high production cost and inability to effectively solve the problem of high flow rate of powder, high purity, no satellite powder, no hollow powder, and difficult to scale up Production and other problems, to achieve good fluidity, improve production efficiency and fine powder yield, pure melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Preparation of Ti-6Al-7Nb alloy spherical powder

[0029] The percentage by weight is: Al5.58%, Nb6.8%, Ta0.45%, Fe0.21%, O0.13%, C0.06%, N0.04%, H0.007%, the rest is Ti, the total The melting and casting raw materials with a weight of 50kg are sequentially subjected to vacuum induction melting and vacuum arc remelting to obtain Ti-6Al-7Nb master alloy ingots;

[0030] Secondly, through the forging process of the master alloy rod, through the machining of the lathe and the precision CNC lathe, a Ti-6Al-7Nb alloy electrode rod with a diameter of 50mm and a length of 850mm is obtained, and the surface roughness is 1.6μm;

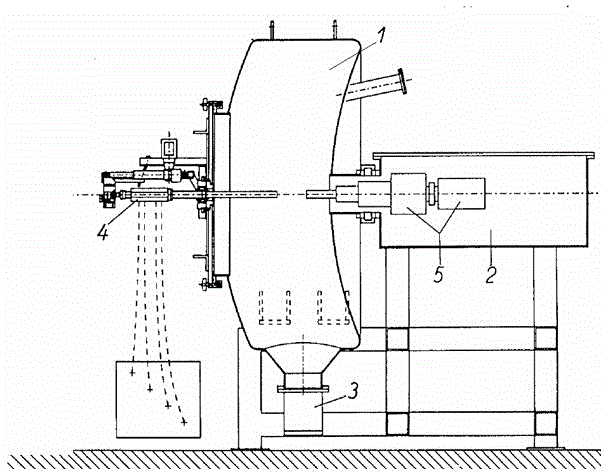

[0031] Place the obtained electrode rod in the electrode rod installation chamber 2, and evacuate the atomization chamber 1 until the vacuum degree of the equipment reaches 1.5×10 -3 Pa filled inert gas mixed with argon and helium, the inert gas pressure in the equipment is 1×10 5 Pa;

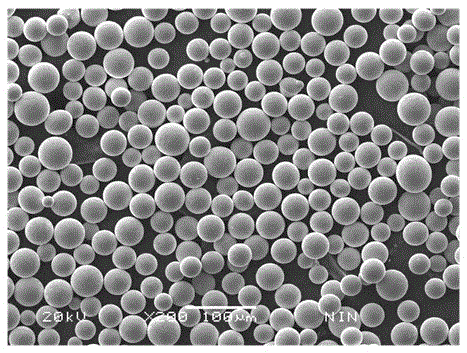

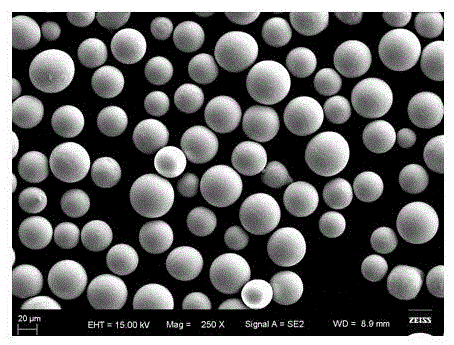

[0032] Turn on the atomization equipment to prep...

Embodiment 2

[0035] Embodiment 2: Preparation of Ti-6Al-7Nb alloy spherical powder

[0036] The percentage by weight is: Al6.12%, Nb7.21%, Ta0.41%, Fe0.20%, O0.11%, C0.07%, N0.04%, H0.008%, the rest is Ti, the total The melting and casting raw materials with a weight of 50kg are sequentially subjected to vacuum induction melting and vacuum arc remelting to obtain Ti-6Al-7Nb master alloy ingots;

[0037]Secondly, through the forging process of the master alloy rod, through the machining of the lathe and the precision CNC lathe, a Ti-6Al-7Nb alloy electrode rod with a diameter of 80mm and a length of 700mm is obtained, and the surface roughness is 1.6μm;

[0038] Place the obtained electrode rod in the electrode rod installation chamber 2, and evacuate the atomization chamber 1 until the vacuum degree of the equipment reaches 1.0×10 -3 Pa filled inert gas mixed with argon and helium, the inert gas pressure in the equipment is 2×10 5 Pa;

[0039] Turn on the atomization equipment to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com