A nanometer porous high-entropy alloy electrode, a preparing method thereof and applications of the electrode

A high-entropy alloy, nano-porous technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., to achieve the effect of rich raw material content, good conductivity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

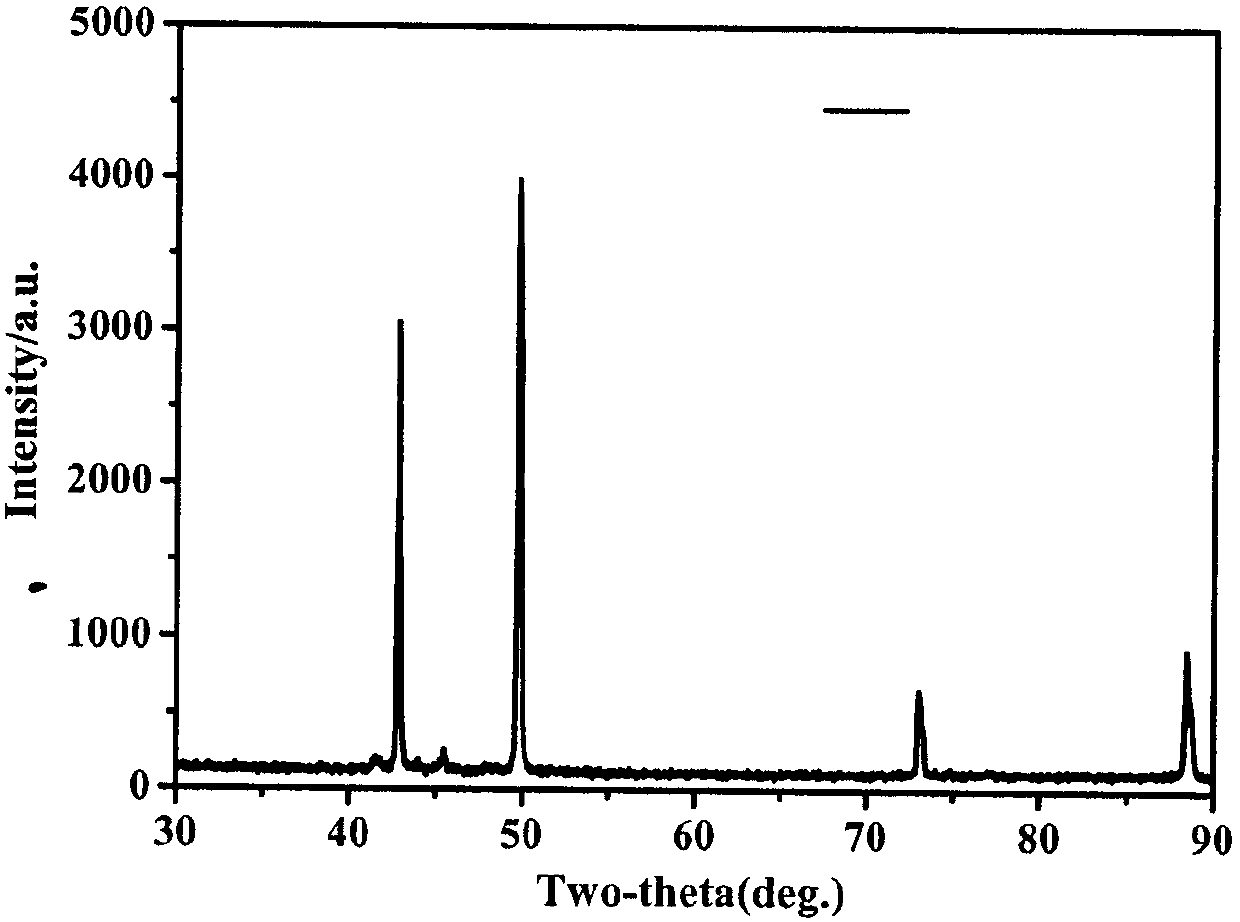

[0027] The preparation method of the nanoporous high-entropy alloy catalytic electrode proposed in this embodiment includes the following steps:

[0028] (1) Prepare alloy: prepare nickel-iron-molybdenum-manganese-cobalt alloy, five kinds of metals Ni:Fe:Mo:Mn:Co are put into smelting furnace according to the ratio of substance amount of 15:15:8:54:8, Melted in a high vacuum melting furnace to form an alloy.

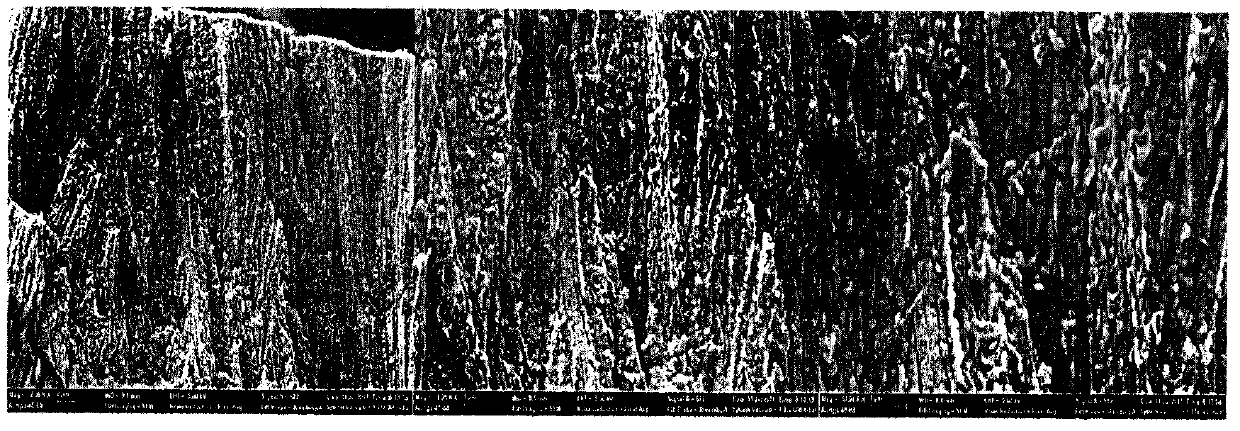

[0029] (2) The alloy strip is obtained by stripping in a strip stripping machine, the width of the alloy strip is 2 mm, and the thickness is 25 μm.

[0030] (3) Dealloying to prepare nanoporous high-entropy alloy electrodes.

[0031] Dealloying adopts electrochemical dealloying method in step screw (3), and concrete steps are as follows:

[0032] The alloy strip prepared in step (2) was prepared by electrochemical dealloying method to prepare nanoporous high-entropy alloy electrode. The dealloying step was: 1mol / L sulfuric acid bismuth was used as dealloying solution, ...

Embodiment 2

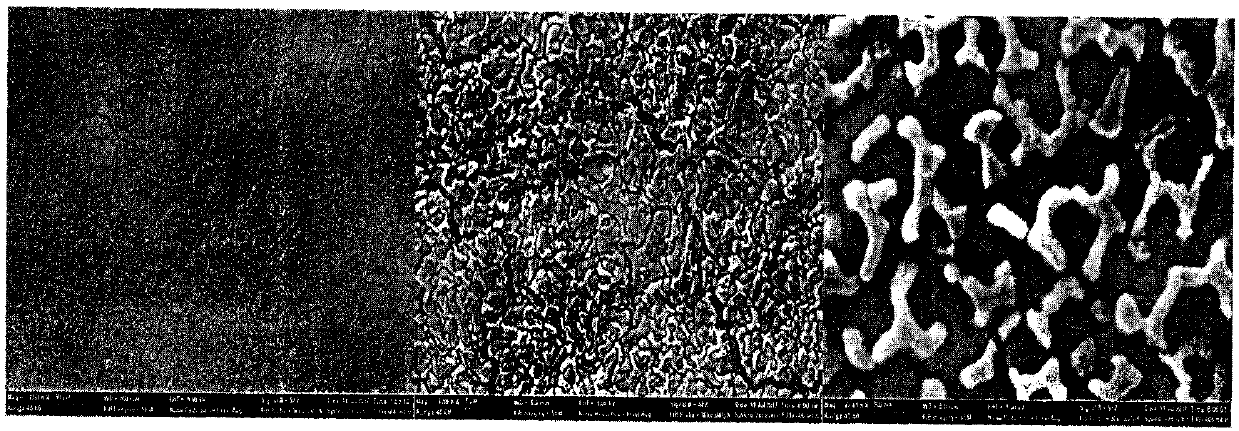

[0042] The only difference from Example 1 is that the dealloying time is changed to 1800 seconds. The catalytic performance of the obtained catalytic electrode: catalytic water electrolysis hydrogen production, at a current density of 100mA / cm 2 and 200mA / cm 2 , the overpotentials are 196mV and 278mV respectively; catalytic water electrolysis produces oxygen, and the current density is 10mA / cm 2 and 100mA / cm 2 , the overpotentials were 298mV and 442mV, respectively.

Embodiment 3

[0044] The only difference from Example 1 is that the dealloying time is changed to 3600 seconds. The catalytic performance of the obtained catalytic electrode: catalytic water electrolysis hydrogen production, at a current density of 100mA / cm 2 and 200mA / cm 2 , the overpotentials are 153mV and 252mV respectively; catalytic water electrolysis produces oxygen, and the current density is 10mA / cm 2 and 100mA / cm 2 , the overpotentials were 273mV and 423mV, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com