Electrochemical method for processing garbage percolate concentrated solution

A technology for landfill leachate and concentrate, which is applied in chemical instruments and methods, electrochemical water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of pollutant accumulation and high cost, and reduce the pollutant concentration. , The effect of reducing salt content and eliminating biological toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

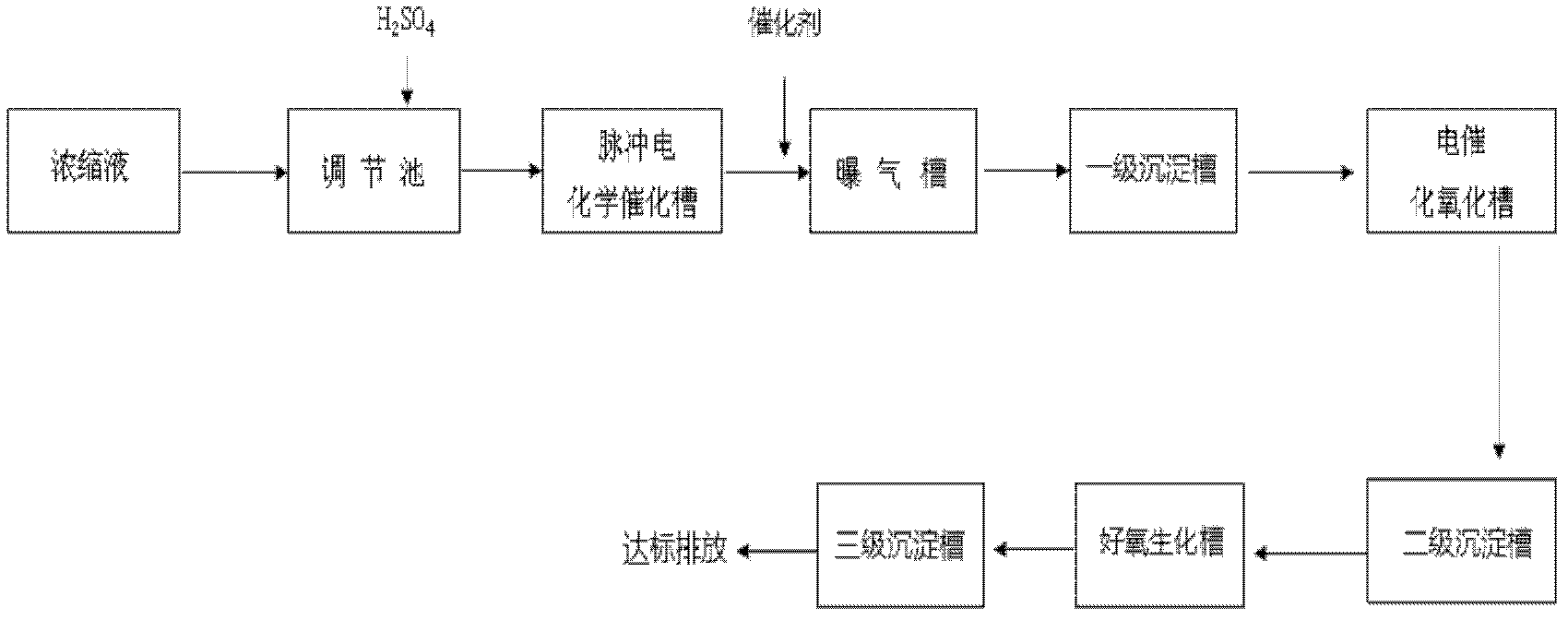

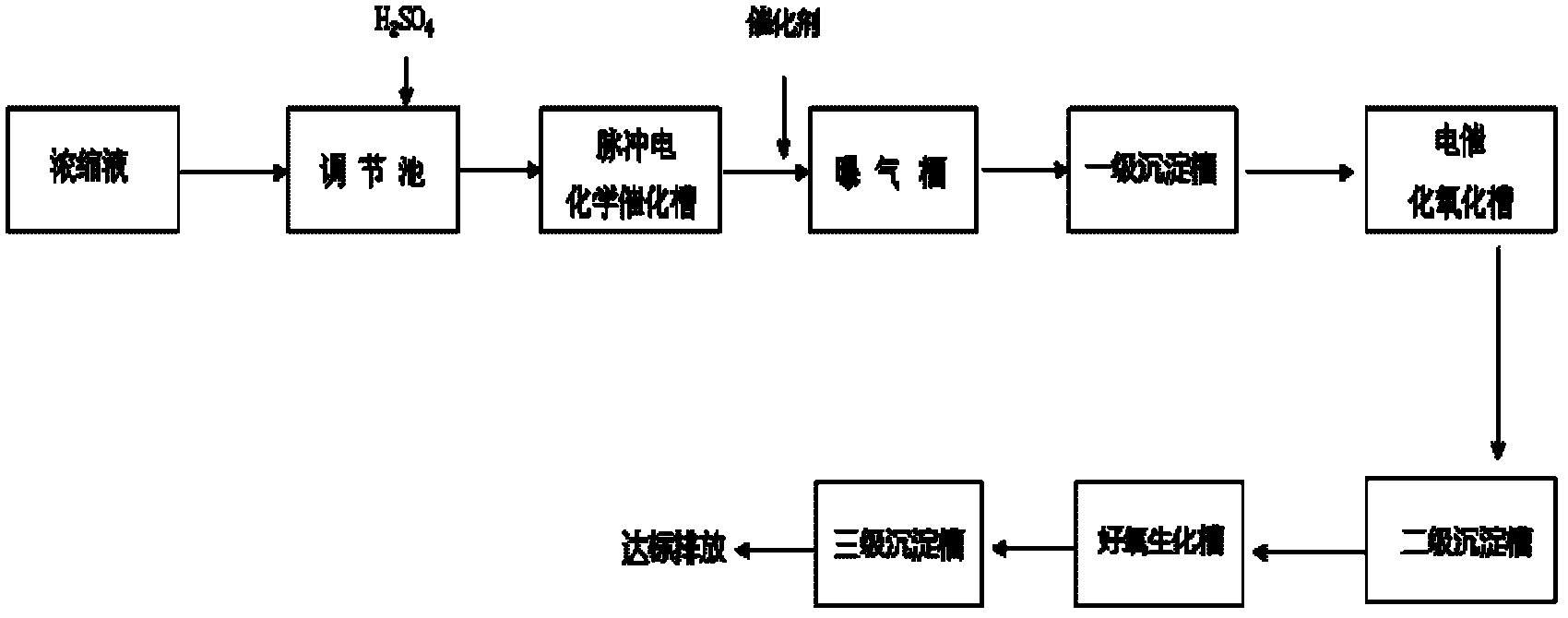

[0034] Such as figure 1 As shown, the present embodiment provides an electrochemical method for treating landfill leachate concentrate, and the steps are as follows:

[0035] a) The leachate concentrate enters the regulating tank, adds sulfuric acid to adjust the pH value to 3, and pumps it into the pulse electrochemical catalytic tank;

[0036] b) Add H to the effluent after the pulse electrochemical catalytic tank reaction 2 o 2 and MnO 2 Finally, go to the aeration tank for aeration-Fenton reaction. The effluent after the reaction in the aeration tank enters the first-stage sedimentation tank for precipitation to obtain the supernatant. The first-stage sedimentation tank is composed of three sedimentation tanks of the same specification in series;

[0037] c) The supernatant after settling in the primary sedimentation tank is pumped into the electrocatalytic oxidation tank for advanced oxidation degradation, which greatly improves the biodegradability of the sewage and m...

Embodiment 2

[0042] Such as figure 1 Shown, a kind of electrochemical method for processing landfill leachate concentrate, its steps are as follows:

[0043] a) The leachate concentrate enters the regulating tank, adds hydrochloric acid to adjust the pH value to 3.5, and pumps it into the pulse electrochemical catalytic tank;

[0044] b) Adding Fe to the effluent after the pulse electrochemical catalytic tank reaction 2+ +H 2 o 2 and MnO 2 Finally, go to the aeration tank for aeration-Fenton reaction. The effluent after the reaction in the aeration tank enters the first-stage sedimentation tank for precipitation to obtain the supernatant. The first-stage sedimentation tank is composed of two sedimentation tanks of the same specification in series;

[0045] c) The supernatant after settling in the primary sedimentation tank is pumped into the electrocatalytic oxidation tank for advanced oxidation degradation, which greatly improves the biodegradability of the sewage and makes the BOD of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com