2H type A5B19 superstacked La-M-Mg-Ni based quaternary hydrogen storage alloy electrode material and preparation method thereof

A technology of A5B19 and hydrogen storage alloys, which is applied in battery electrodes, structural parts, nickel storage batteries, etc., can solve the problems that the preparation method of quaternary hydrogen storage alloys has not been reported, the difficulty of quaternary single-phase alloys increases, and the phase transition reaction is complicated. , to achieve excellent high-rate discharge performance, excellent electrochemical cycle stability, and reduce thermal uneven deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

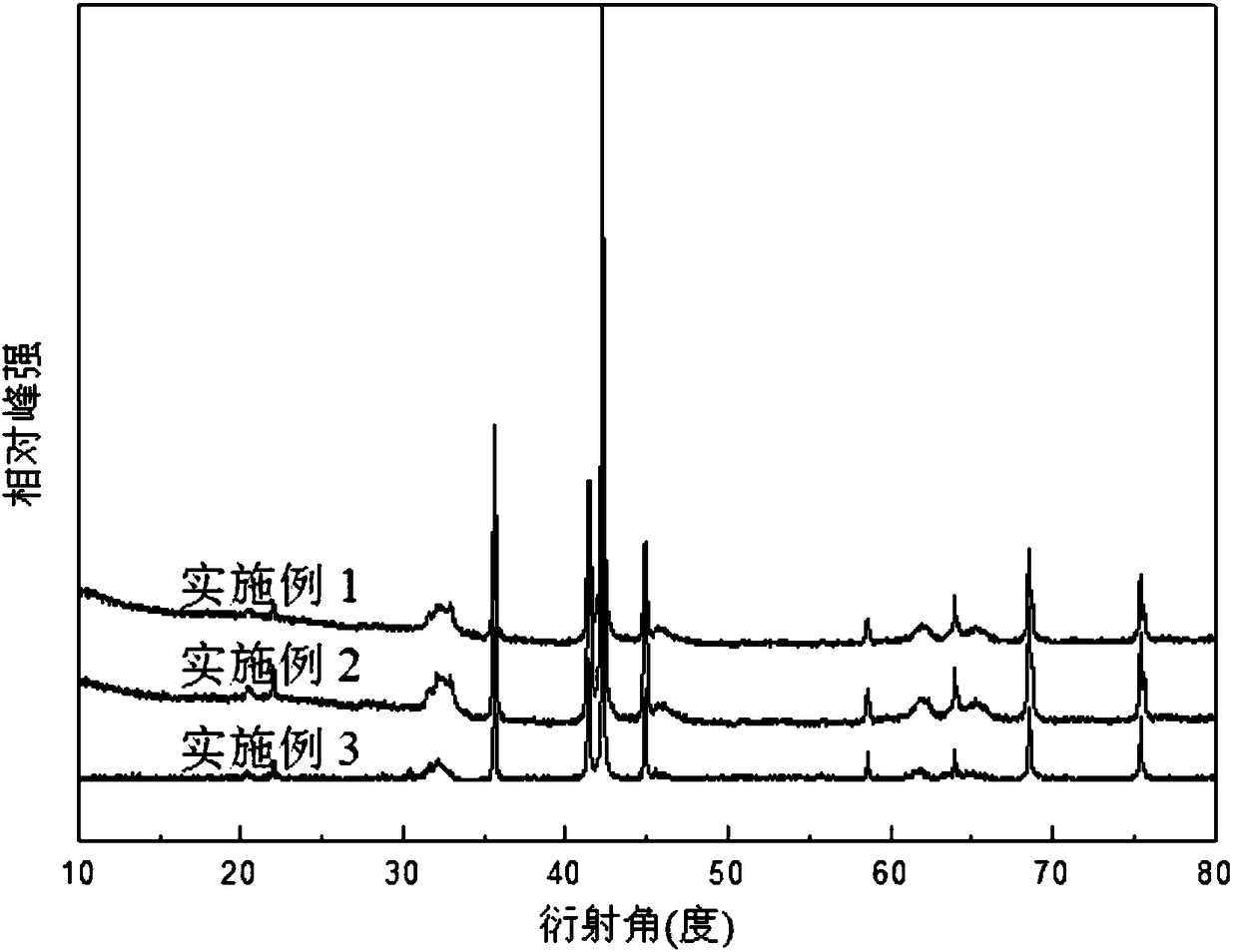

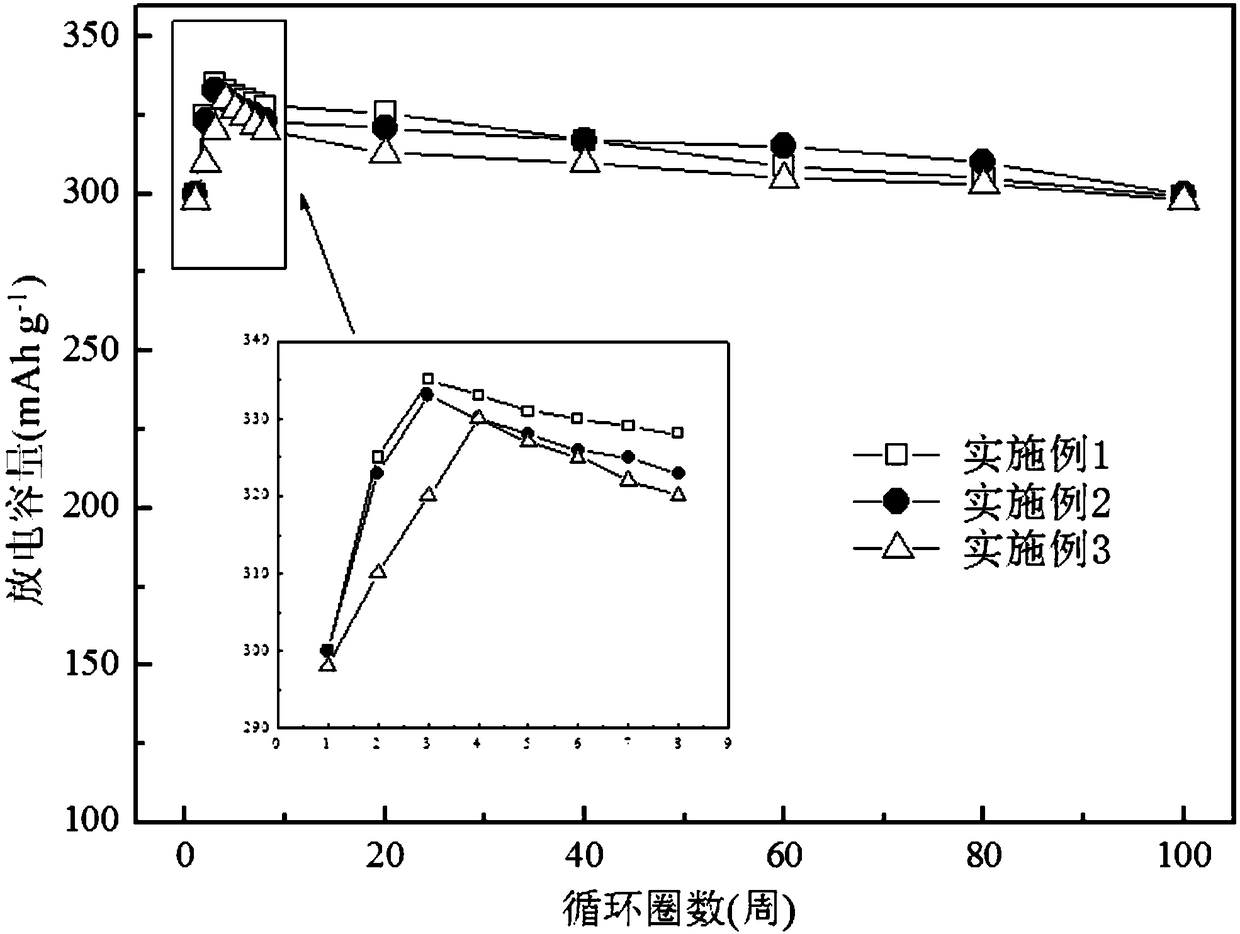

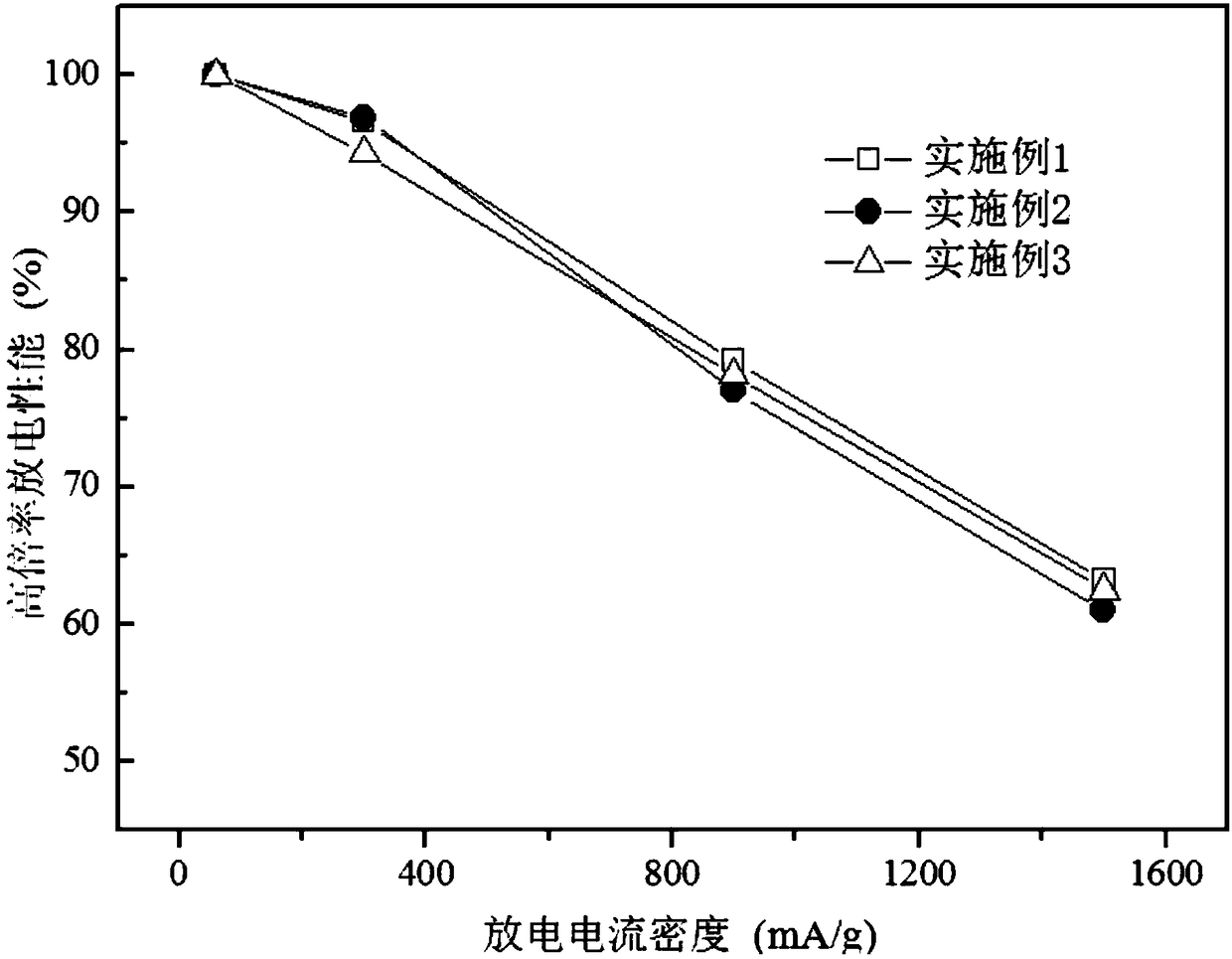

Embodiment 1

[0035] (1) Ingredients

[0036] La obtained by induction melting 0.65 PR 0.15 Mg 0.2 Ni 3.65 and LaMgNi 4 Alloy ingots were used as precursors, and were pulverized to 300 mesh under argon atmosphere, according to the molar ratio La 0.65 PR 0.15 Mg 0.2 Ni 3.65 : LaMgNi 4 =0.9:1 (ie: 1.058g of La 0.65 PR 0.15 Mg 0.2 Ni 3.65 and 1.442 g of LaMgNi 4 Alloy powder) is mixed evenly;

[0037] (2) ball mill

[0038] The mixture in step (1) was ball-milled for 1 h under an argon atmosphere, the ball-to-material ratio was 30:1, and the rotational speed was 100 r / min. The ball-milling procedure was ball milling for 20 minutes with an interval of 20 minutes; b1;

[0039] (3) Tablet

[0040] The mixture of step (2) is cold-pressed and formed under a pressure of 10MPa, and wrapped and welded and sealed with a nickel plate;

[0041] (4) Sintering

[0042] The pressed sheet of step (3) is placed in the vacuum sintering furnace and sealed, and the vacuum degree is 5 × 10 -3 ...

Embodiment 2

[0053] (1) Ingredients

[0054] La obtained by induction melting 0.65 Nd 0.15 Mg 0.2 Ni 3.65 and LaMgNi 4 Alloy ingots were used as precursors, and were pulverized to 400 mesh under argon atmosphere, according to the molar ratio La 0.65 Nd 0.15 Mg 0.2 Ni 3.65 : LaMgNi 4 =0.74:1 (ie: 0.95g of La 0.65 Nd 0.15 Mg 0.2 Ni 3.65 and 1.55 g of LaMgNi 4 Alloy powder) is mixed evenly;

[0055] (2) ball mill

[0056] The mixture in step (1) was ball-milled for 0.5 h under an argon atmosphere, the ball-to-material ratio was 30:1, the rotational speed was 100 r / min, the ball-milling program was ball-milling for 20 minutes, and an interval of 20 minutes; after the ball-milling was completed, it was naturally cooled to room temperature and taken out;

[0057] (3) Tablet

[0058] The mixture of step (2) is cold-pressed and formed under a pressure of 10MPa, and wrapped and welded and sealed with a nickel plate;

[0059] (4) Sintering

[0060] The pressed sheet of step (2) is ...

Embodiment 3

[0071] (1) Ingredients

[0072] La obtained by induction melting 0.65 Gd 0.15 Mg 0.2 Ni 3.65 and LaMgNi 4 Alloy ingots were used as precursors, and were pulverized to 350 mesh under argon atmosphere, according to the molar ratio La 0.65Gd 0.15 Mg 0.2 Ni 3.65 : LaMgNi 4 =0.625:1 (ie: 0.85g of La 0.65 Gd 0.15 Mg 0.2 Ni 3.65 and 1.65 g of LaMgNi 4 Alloy powder) is mixed evenly;

[0073] (2) ball mill

[0074] The mixture in step (1) was ball-milled for 0.8 h under an argon atmosphere, the ball-to-material ratio was 30:1, and the rotation speed was 100 r / min. The ball-milling procedure was ball milling for 20 minutes with an interval of 20 minutes; after the ball milling was completed, it was naturally cooled to room temperature and taken out;

[0075] (3) Tablet

[0076] The mixture of step (2) is cold-pressed and formed under a pressure of 10MPa, and wrapped and welded and sealed with a nickel plate;

[0077] (4) Sintering

[0078] Place the pressed tablet of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com