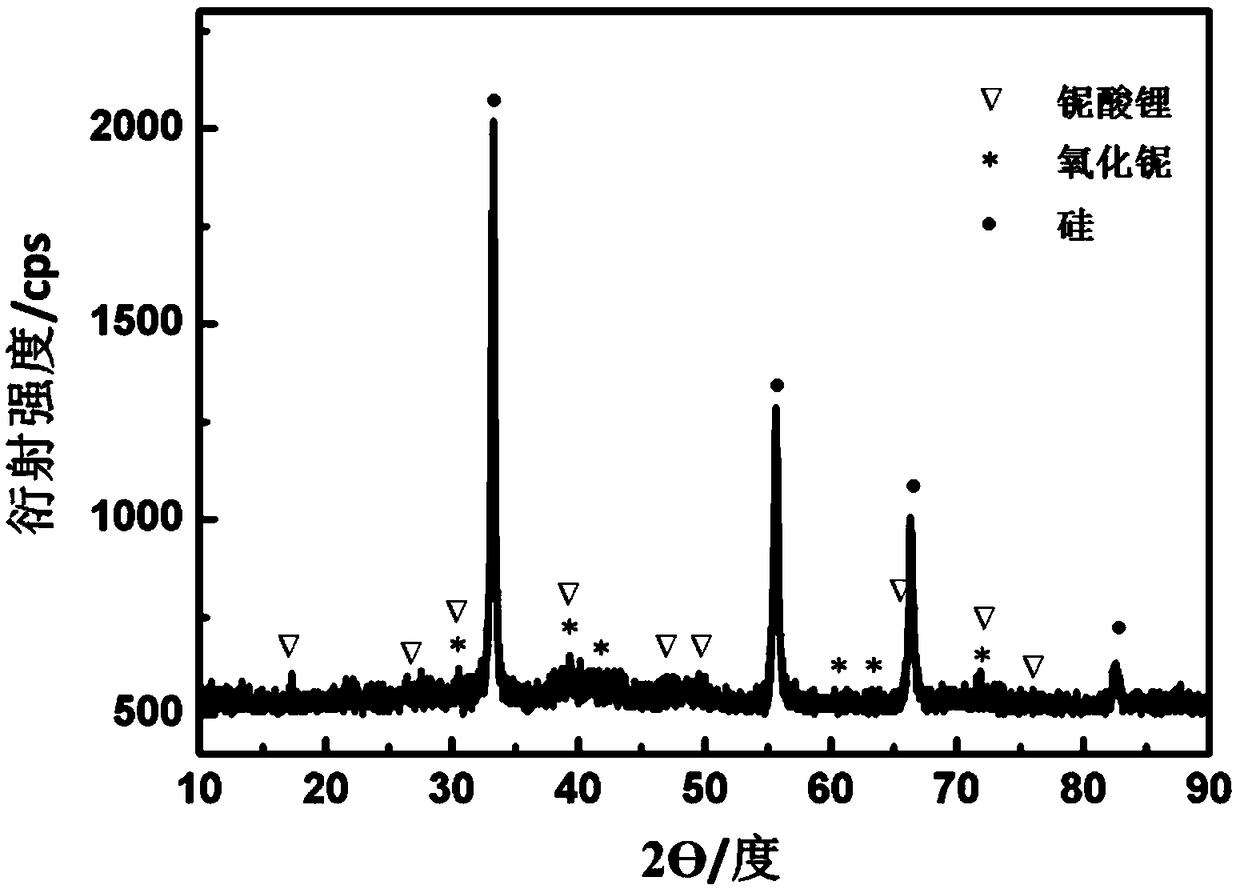

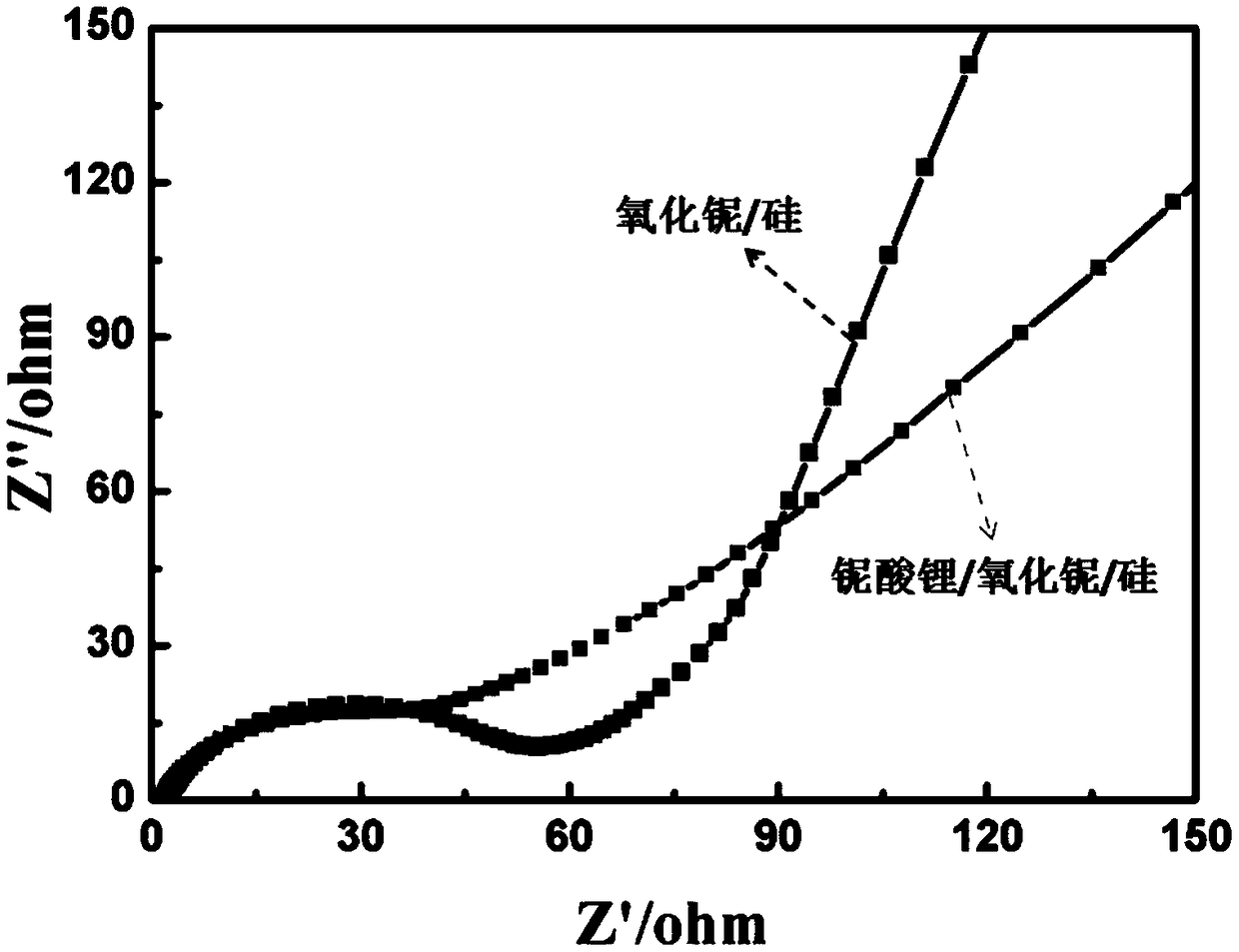

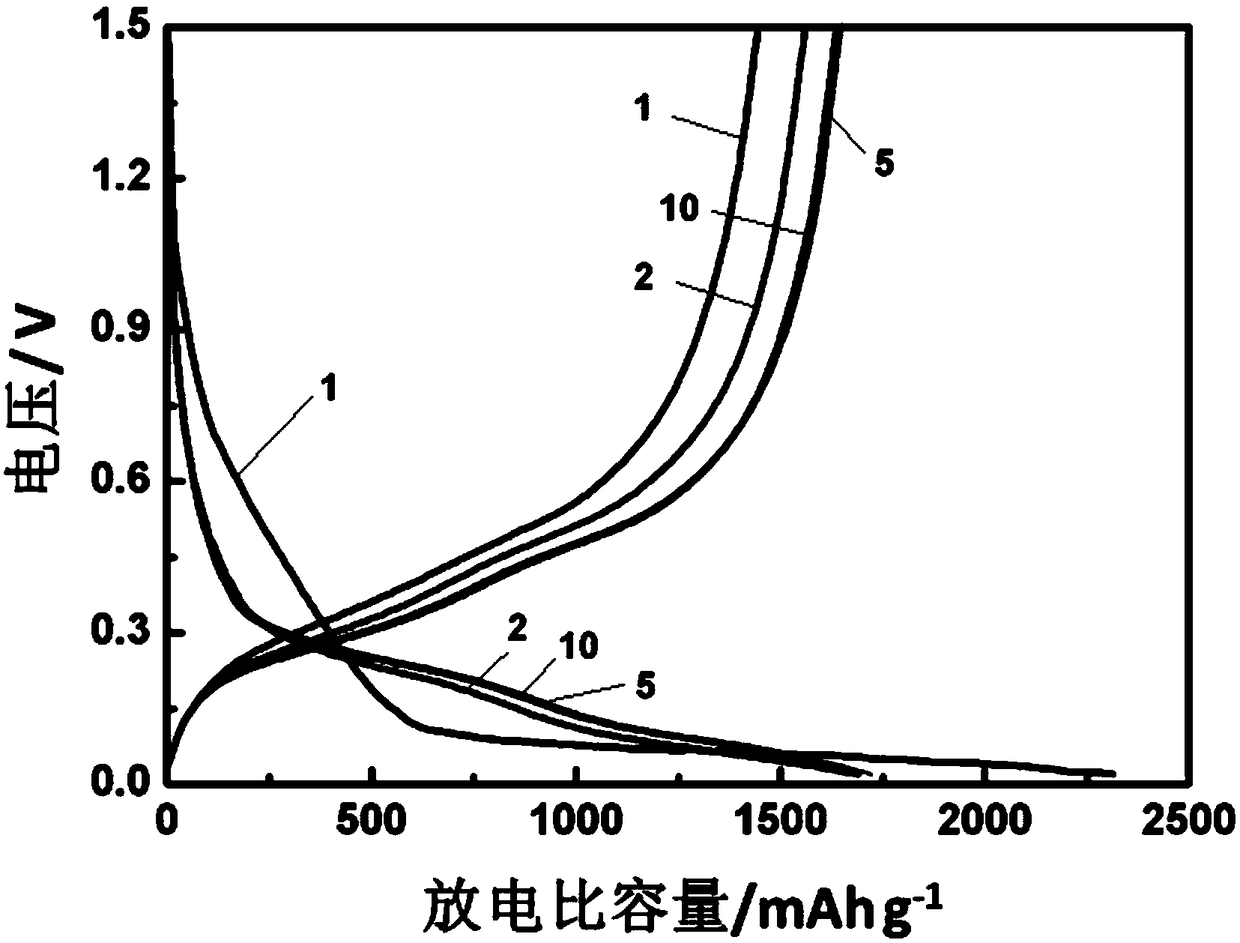

Lithium niobite/niobium-base oxide/silicon compound cathode material, preparation method and application thereof

A negative electrode material and oxide technology, which is applied in the field of lithium niobate/niobium-based oxide/silicon composite negative electrode system and its preparation, can solve the problems of unstable ion transport and poor ion conductivity, and achieve good electrochemical cycle stability , the preparation method is simple, the effect of high batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method with lithium niobate / niobium-based oxide / silicon composite negative electrode material has the following steps:

[0049] S1. Add 0.538g of silicon powder (average particle size of 50nm) into 40mL of ethanol solution (analytical grade) and ultrasonically vibrate for 30 minutes to obtain a uniformly mixed silicon powder / alcohol solution: silicon powder / ethanol solution;

[0050] S2. Dissolve 0.538g of niobium chloride in 40ml of ethanol solution and vigorously stir for 30min to obtain a uniform oxide precursor / alcohol solution: clear ethanol solution of niobium chloride;

[0051] S3, adding the silicon powder / alcohol solution obtained in step S1 to the niobium chloride ethanol solution obtained in step S2 and vigorously stirring for 30min to obtain the ethanol mixed solution of 80mL silicon powder-niobium chloride, Nb in the solution 5+ The molar concentration is 0.0250mol L -1 ;

[0052] S4, move the 80mL silicon powder-niobium chloride ethanol mix...

Embodiment 2

[0058] A preparation method with lithium niobate / niobium-based oxide / silicon composite negative electrode material has the following steps:

[0059] S1. Add 0.863g of silicon powder (average particle size of 50nm) into 30mL of ethylene glycol solution (analytical pure) and ultrasonically vibrate for 40min to obtain a uniformly dispersed silicon powder / ethylene glycol solution;

[0060] S2, 0.807g niobium oxalate was dissolved in 30ml of ethylene glycol solution and vigorously stirred for 40min to obtain a clear niobium oxalate ethylene glycol solution for subsequent use;

[0061] S3, adding the silicon powder / ethylene glycol solution obtained in step S1 to the niobium oxalate ethylene glycol solution obtained in step S2 and vigorously stirring for 40min to obtain the ethylene glycol mixed solution of 60mL silicon-niobium oxalate, Nb in the solution 5+ The molar concentration is 0.0250mol L -1 ;

[0062] S4. Move the ethylene glycol mixed solution of silicon-niobium oxalate p...

Embodiment 3

[0067] A preparation method with lithium niobate / niobium-based oxide / silicon composite negative electrode material has the following steps:

[0068] S1. Add 0.538g of silicon powder (average particle size of 50nm) into 40mL of methanol solution (analytical pure) and ultrasonically vibrate for 30min to obtain a uniformly dispersed silicon powder / methanol solution;

[0069] S2, 0.538g of niobium chloride and 0.340g of tetrabutyl titanate were successively dissolved in 40ml of methanol solution and vigorously stirred for 1h to obtain a clear mixed solution of niobium chloride / tetrabutyl titanate in methanol;

[0070] S3. Add the silicon powder / methanol solution obtained in step S1 to the mixed solution prepared in step S2 and stir vigorously for 40 minutes to obtain 80 mL of methanol mixed solution of silicon-niobium chloride / tetrabutyl titanate. In the solution, Nb 5+ The molar concentration is 0.0250molL -1 , Ti 3+ The molar concentration is 0.0125mol L -1 ;

[0071]S4. Mov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com