Electrolyte containing inorganic additive and lithium-ion battery containing electrolyte

A lithium-ion battery, inorganic additive technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of reducing battery cycle performance and stability, easily generating hydrogen fluoride, polluting the environment, etc., achieving good cycle performance, reducing water The effect of content and coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

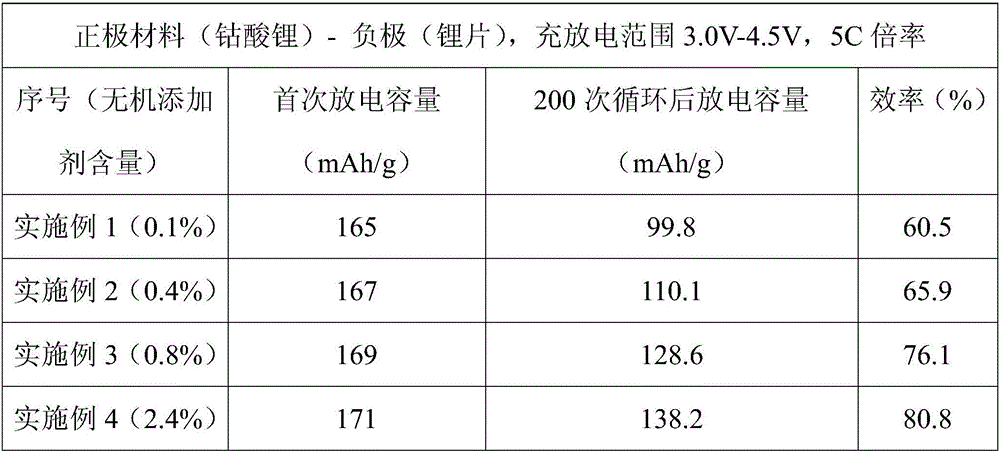

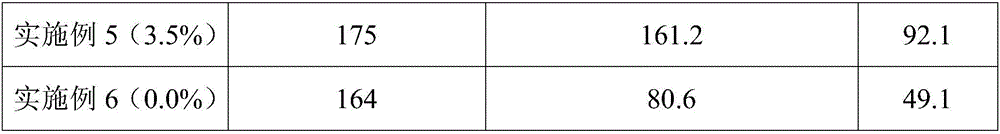

[0036] The electrolyte uses a mixture of ethylene carbonate (EC), diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) with a weight ratio of 1:1:1 as the organic solvent, and the electrolyte uses 1M LiCF 3 SO 3 , 1% organic additives (VC:ES=1:1), 0.1% inorganic additives (SiO 2 :Al 2 O 3 =1:2), mix well. Lithium cobalt oxide is used as the positive electrode material, and the lithium sheet is used as the negative electrode material. The button battery is assembled and tested. The charge and discharge range is 3.0V-4.5V. The test results are shown in Table 1.

Embodiment 2

[0038] The electrolyte uses a mixture of ethylene carbonate (EC), diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) with a weight ratio of 1:1:1 as the organic solvent, and the electrolyte uses 1M LiCF 3 SO 3 , 1% organic additives (VC:ES=1:1), 0.4% inorganic additives (SiO 2 :Al 2 O 3 =1:2), mix well. Lithium cobaltate was used as the positive electrode material, and the lithium sheet was used as the negative electrode material. They were assembled into a button cell and tested. The charge and discharge range is 3.0V-4.5V. The test results are shown in Table 1.

Embodiment 3

[0040] The electrolyte uses a mixture of ethylene carbonate (EC), diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) with a weight ratio of 1:1:1 as the organic solvent, and the electrolyte uses 1M LiCF 3 SO 3 , 1% organic additives (VC:ES=1:1), 0.8% inorganic additives (SiO 2 :Al 2 O 3 =1:2), mix well. Lithium cobaltate was used as the positive electrode material, and the lithium sheet was used as the negative electrode material. They were assembled into a button cell and tested. The charge and discharge range is 3.0V-4.5V. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com