Power battery hydrogen storage electrode alloy and preparation method thereof

An electrode alloy and power battery technology, which is applied in the field of hydrogen storage alloy materials, can solve the problems that the electrochemical performance is difficult to meet the requirements of Ni/MH batteries, and cannot meet the practical requirements of the performance stability of hydrogen storage alloys, and achieves electrochemical performance. Excellent cycle stability, improved electrochemical cycle stability, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

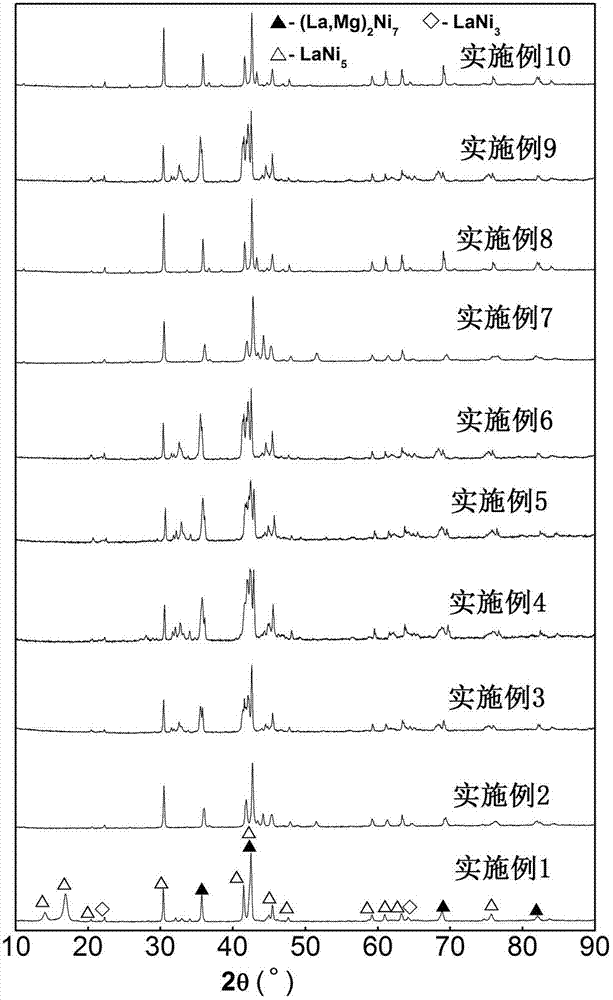

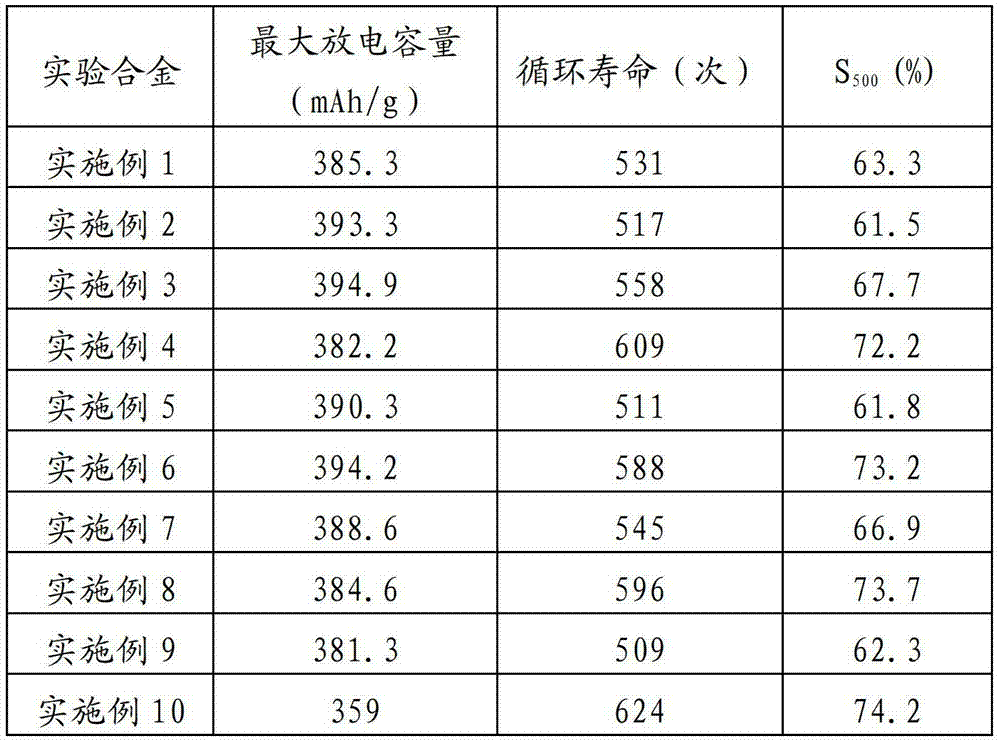

[0022] refer to figure 1 , the metal raw material La that is weighed according to the chemical formula composition 0.72 Ce 0.1 Mg 0.18 Ni 3.4 al 0.1 Put it in the magnesia crucible of the intermediate frequency induction furnace, then cover the furnace cover, and evacuate to a vacuum degree of 4.5×10 -2 Pa, then fill in the mixed gas of argon + helium to reach the negative pressure of 0.04MPa, control the temperature at about 1450°C, adjust the power to melt all the metal, and become a molten liquid master alloy, keep it under the melting condition for 5 minutes, and then put the liquid alloy Inject into the tundish, and continuously spray it on the smooth surface of the water-cooled copper roller rotating at a line speed of 8m / s through the boron nitride nozzle at the bottom of the tundish to obtain fast-quenched alloy flakes; put the fast-quenched alloy into a vacuum heat treatment furnace , evacuated to 4.5×10 -3Pa, heated to 650°C for 4 hours, then cooled to room tem...

Embodiment 2-10

[0024] refer to figure 1 , the chemical composition and the ratio selection of specific embodiments of the present invention 2-10 are as follows:

Embodiment 2

[0025] Example 2: La 0.62 Ce 0.1 SM 0.1 Mg 0.18 Ni 3.4 al 0.1

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com