Phosphorus/carbon composite negative electrode material of lithium ion battery and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of restricting the development and application of black phosphorus negative electrode materials, difficult industrialization of black phosphorus negative electrodes, and fast capacity decay of black phosphorus, etc. The effect of electrochemical cycle stability, easy large-scale industrial production, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Weigh 8g of red phosphorus and 2g of graphite according to the ratio of P / C mass ratio of 8 / 2 and manually grind them with an agate mortar for 2 hours to mix them evenly, put the above mixture into a stainless steel tank, and add 500g of stainless steel balls. After being sealed with nitrogen gas, ball milling was carried out for 30 hours at a speed of 550 rpm to obtain a black powder product.

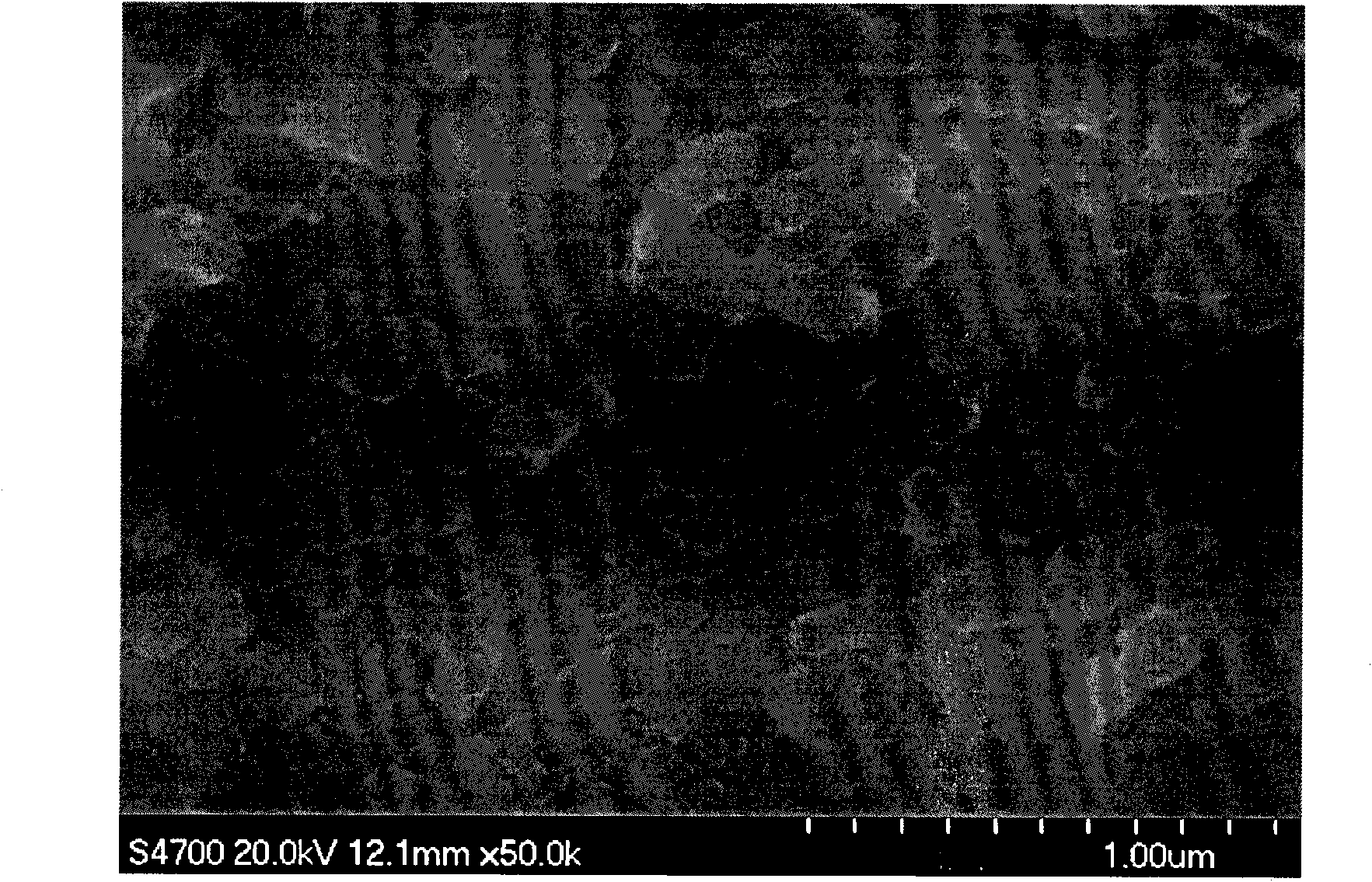

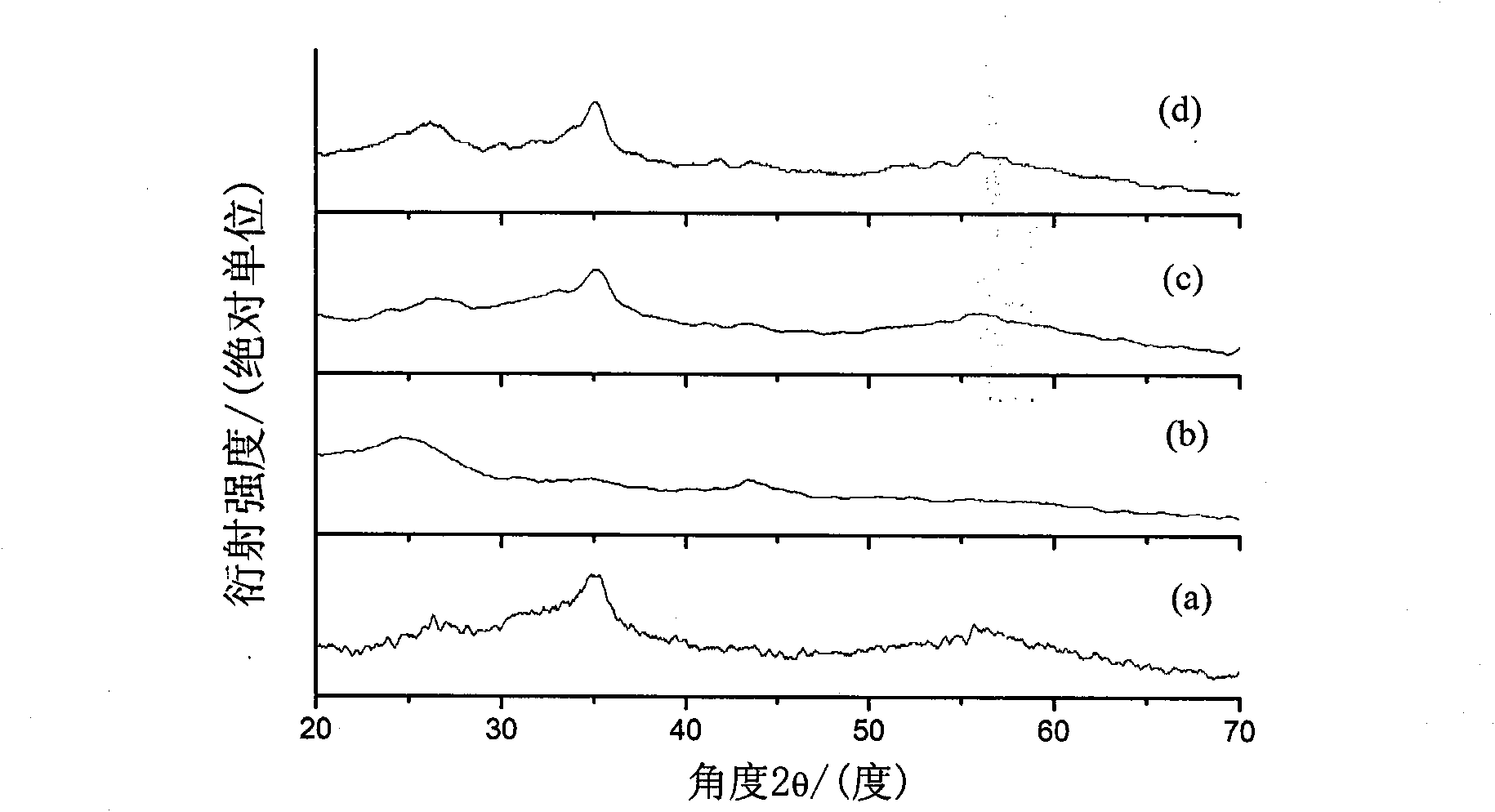

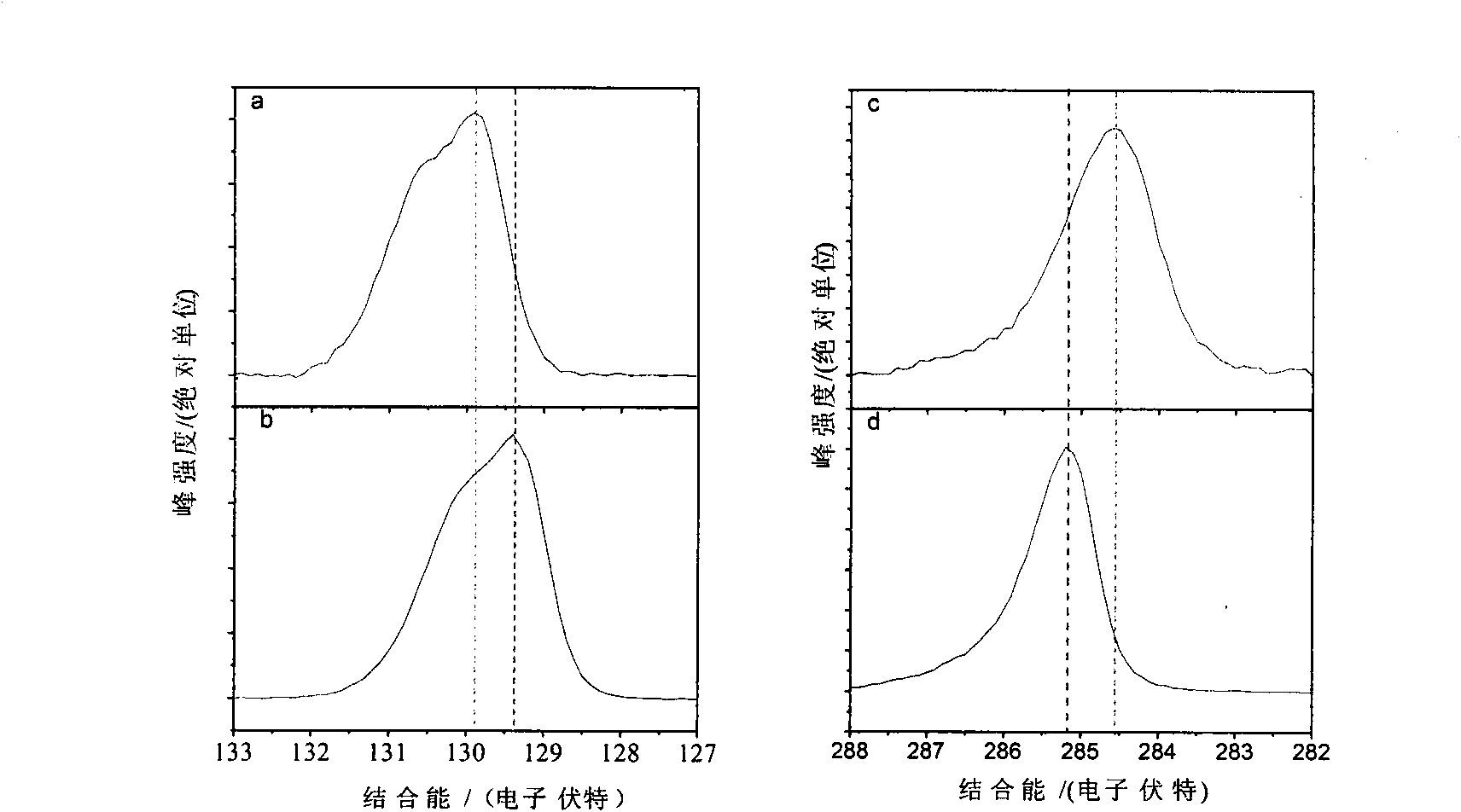

[0038] The morphology of the phosphorus / carbon composite was characterized by a Hitachi S-4700 field emission scanning electron microscope, and the test results were as follows: figure 1 shown. Adopt Japan Shimadzu XRD-6000 type X-ray powder diffractometer to characterize the product structure as amorphous structure, its XRD test result is as follows figure 2 as shown in a. The PHI Quantera SXM type X-ray photoelectron energy spectrometer of Japan Vacuum-PHI Company was used to characterize the bonding situation between atoms in the product, and the XPS test results before and...

Embodiment 2

[0040] Weigh 4g of red phosphorus and 6g of acetylene black according to the ratio of P / C mass ratio of 4 / 6 and manually grind them with an agate mortar for 2 hours to mix them evenly. Put the above mixture into a stainless steel tank and add 200g of stainless steel balls. After being sealed with nitrogen gas, ball milling was performed for 15 hours at a speed of 450 rpm to obtain a black powder product.

[0041] Adopt Japan Shimadzu XRD-6000 type X-ray powder diffractometer to characterize the product structure as amorphous structure, its XRD test result is as follows figure 2 as shown in b. The electrochemical performance test was carried out by Wuhan Landian CT 2001A battery test system, at 2.0~0.1V (vs. Li + / Li) range, the first discharge and charge curves such as Figure 4 As shown in b, the first discharge and charge specific capacities are 1354.6 and 1061.3mAh / g, respectively. Electrochemical cycle performance curves such as Figure 5 As shown in a, at 2.0~0.1V (v...

Embodiment 3

[0043] Weigh 3g of red phosphorus and 7g of acetylene black according to the ratio of P / C mass ratio of 7 / 3 and manually grind them with an agate mortar for 2 hours to mix them evenly. Put the above mixture into a stainless steel tank and add 800g of stainless steel balls. After sealing with nitrogen gas, ball mill for 20 hours under the condition of rotating speed of 350 rpm to obtain a black powder product.

[0044] Adopt Japan Shimadzu XRD-6000 type X-ray powder diffractometer to characterize the product structure as amorphous structure, its XRD test result is as follows figure 2 as shown in c. The electrochemical performance test was carried out by Wuhan Landian CT 2001A battery test system, at 2.0~0.1V (vs.Li + / Li) range, the first discharge and charge curves such as Figure 4 As shown in c, the first discharge and charge specific capacities are 2194.3 and 1755.1mAh / g, respectively. At 2.0~0.78V (vs. Li + After 40 cycles in the range of / Li), the discharge and charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com