Double-coating diaphragm capable of simultaneously inhibiting lithium dendrites and shuttle effect and preparation method thereof

A shuttle effect, double-coating technology, applied in lithium batteries, structural parts, electrical components, etc., to achieve the effect of inhibiting lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of a dual-coated separator that simultaneously suppresses lithium dendrites and shuttling effects:

[0030] 1) Preparation of Zn-MOF powder material: Dissolve 1mmol of adenine and 1mmol of 4,4-biphenyldicarboxylic acid (with a molar ratio of 1:1) in 20mL of DMF and ultrasonically dissolve to obtain solution A and solution B for later use , 1mmol of zinc acetate and 1g of polyvinylpyrrolidone were dissolved in 20 mL of DMF and ultrasonically dissolved to obtain solution C for later use. Mix solution A, solution B and solution C in a volume ratio of 1:1:1, and add volume The activated ratio is 5:4:1, dispersed in DMF, methanol and deionized water, and stirred at room temperature for 12 hours;

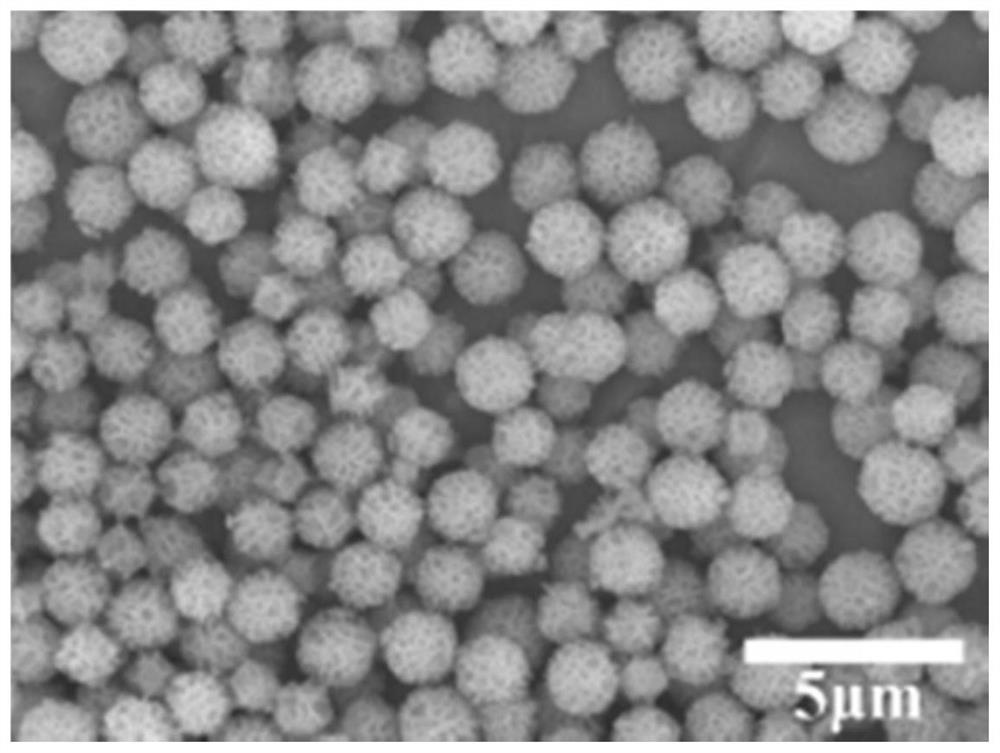

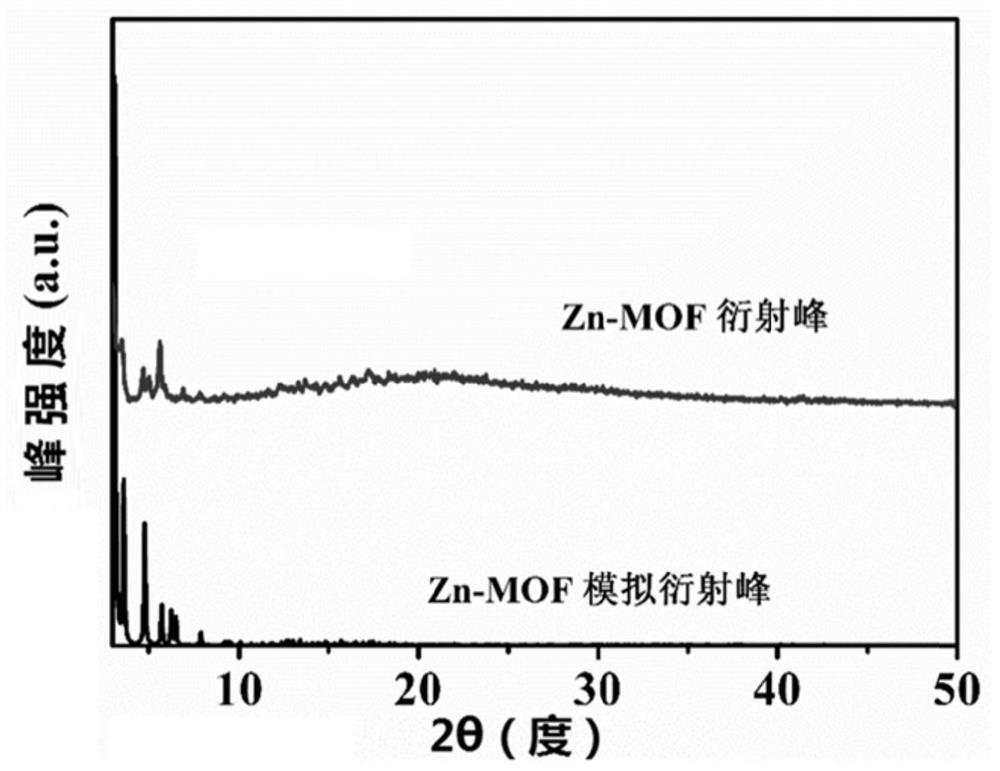

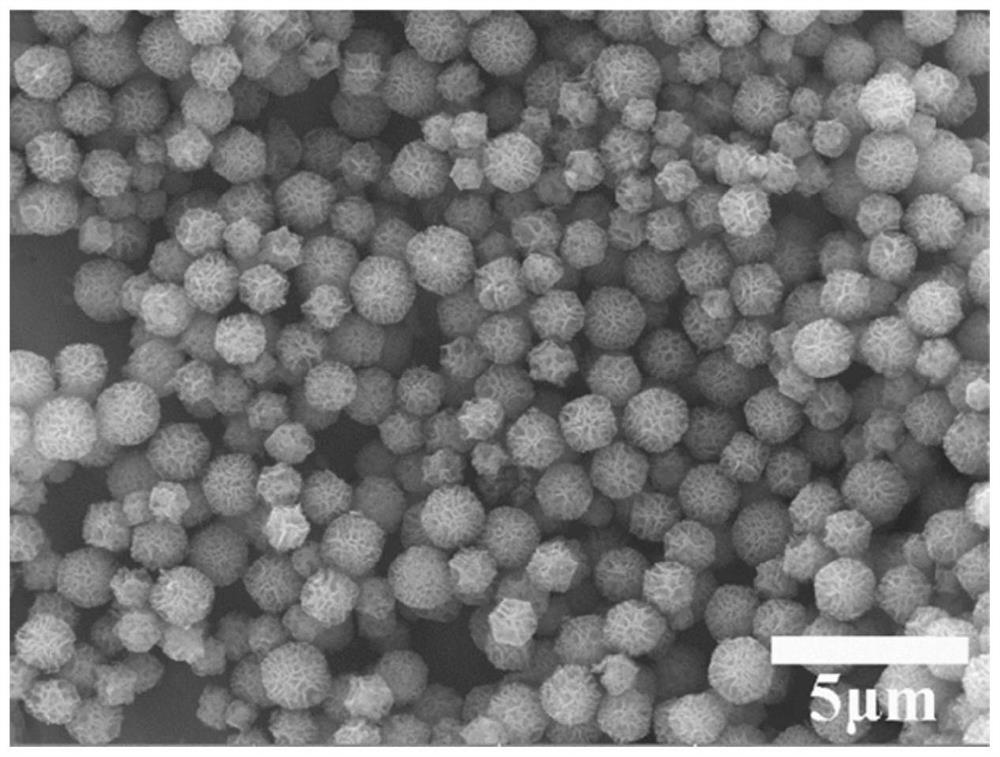

[0031] After the reaction stopped, under 8000r / min, centrifugal 5min, obtain white powder, after it is washed with DMF, MeOH successively, obtain Zn-MOF powder body material after drying in oven, as figure 1 Shown is the scanning electron microscope image of Zn-MOF pow...

Embodiment 2

[0036] Preparation of a dual-coated separator that simultaneously suppresses lithium dendrites and shuttling effects:

[0037]1) Preparation of Zn-MOF powder material: Dissolve 1mmol of adenine and 1mmol of 4,4-biphenyldicarboxylic acid in 20mL of DMF and ultrasonically dissolve it for later use; dissolve 1mmol of zinc acetate and 1g of polyvinylpyrrolidone in 20mL of Ultrasonic dissolution in DMF for standby, mix the above three DMF solutions with a volume ratio of 1:1:2, add the activated volume ratio of 5:4:1 and disperse them in DMF, methanol and deionized water, at room temperature Stir for 18h;

[0038] After the reaction is stopped, centrifuge at 8000r / min for 5min to obtain a white powder, which is washed with DMF and MeOH in turn, and dried in an oven to obtain a Zn-MOF powder material;

[0039] 2) Preparation of ZnNC carbon material: Calcining the Zn-MOF powder material prepared in step 1) in a tube furnace under a nitrogen atmosphere, calcining at 800°C for 4h, and...

Embodiment 3

[0043] Preparation of a dual-coated separator that simultaneously suppresses lithium dendrites and shuttling effects:

[0044] 1) Preparation of Zn-MOF powder material: Dissolve 1 mmol of adenine and 1 mmol of 4,4-biphenyldicarboxylic acid in 20 mL of DMF and ultrasonically dissolve them for later use; mix 1 mmol of zinc acetate with 1 g of polyvinylpyrrolidine Dissolve the ketone in 20 mL DMF and ultrasonically dissolve it for later use. Mix the above three DMF solutions at a ratio of 1:1:4 by volume, and add the activated dispersant in DMF, methanol, and Ionized water, stirred at room temperature for 24h;

[0045] After the reaction stopped, centrifuge at 8000 r / min for 5 min to obtain a white powder, which was washed with DMF and MeOH in turn, and dried in an oven to obtain a Zn-MOF powder material;

[0046] 2) Preparation of ZnNC carbon material: calcining the Zn-MOF powder material prepared in step 1) in a tube furnace under a nitrogen atmosphere, calcining at 800°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com