Preparation method of sodium ion battery positive electrode material with coating structure

A sodium-ion battery and positive electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problem that the cycle performance and rate performance cannot be fully matched, the crystal structure is unstable, and the storage is stable Poor performance and other problems, to achieve the effect of improving air storage stability, improving cycle stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

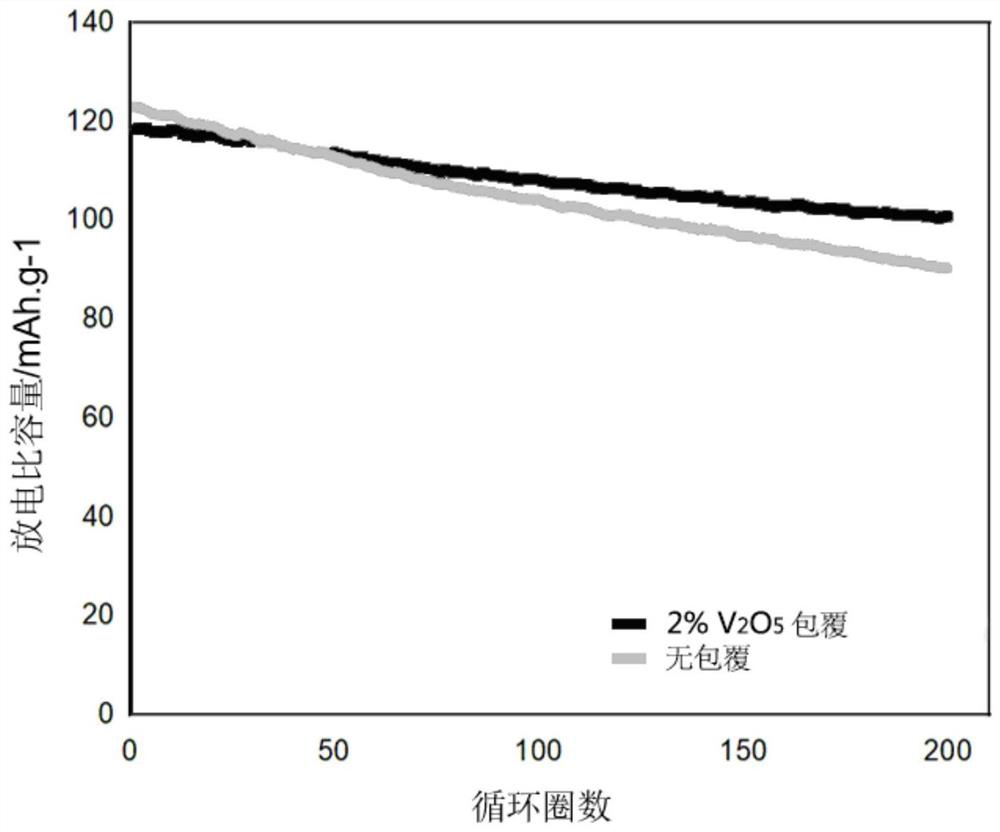

[0021] 0.0643g NH 4 VO 3 Disperse in 20mL absolute ethanol (NH 4 VO 3 The ratio to the mass of absolute ethanol is 0.004:1), under constant stirring, with a coating mass percentage of 2% V 2 o 5 Calculated by adding 2.5g NaNi 1 / 3 Fe 1 / 3 mn 1 / 3 o 2 The material was evaporated to dryness in a water bath at 80°C, heat-treated at 550°C for 3 hours, and cooled naturally to obtain the coating material.

Embodiment 2

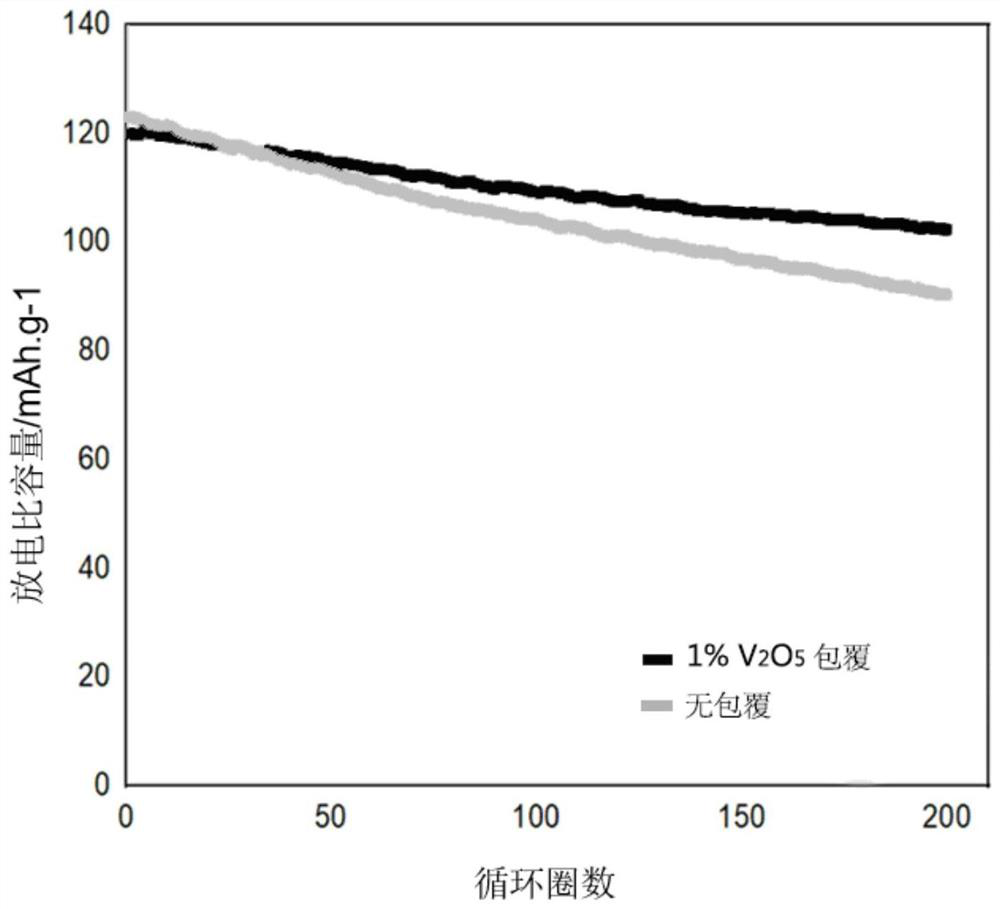

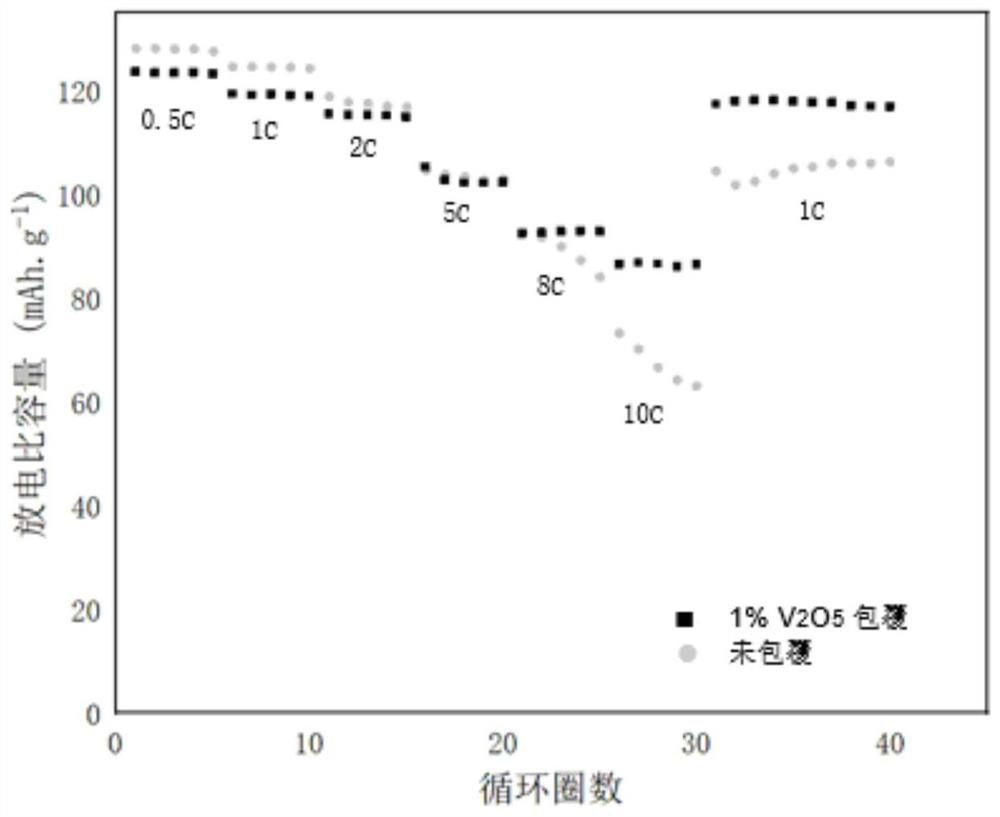

[0023] 0.032g NH 4 VO 3 Disperse in 20mL absolute ethanol (NH 4 VO 3 The ratio to the mass of absolute ethanol is 0.002:1), under constant stirring, the coating mass percentage is 1% V 2 o 5 Calculated by adding 2.5g NaNi 1 / 3 Fe 1 / 3 mn 1 / 3 o 2 The material was evaporated to dryness in a water bath at 80°C, heat-treated at 550°C for 3 hours, and cooled naturally to obtain the coating material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com