Method for preparing spinel lithium titanate nano piece and application of spinel lithium titanate nano piece in lithium battery

A technology of lithium lithium titanate and nanosheets, which is applied in the preparation of spinel lithium titanate nanosheets and its application in lithium batteries, can solve problems such as potential safety hazards and metal lithium deposition, and achieve easy operation and low cost. Low, high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

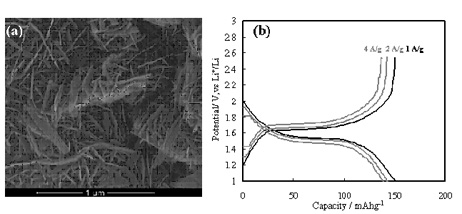

[0010] The specific steps of a preparation method of spinel lithium titanate nanosheets are as follows: mixing 0.5-2.0 grams of titanium dioxide powder with 40-50 milliliters of potassium hydroxide solution with a concentration of 10-20 mol / liter, at 160 ℃-200 ℃ Reaction for 48-96h, after the reactant is washed with dilute hydrochloric acid, take 0.1-0.5 g of reactant and mix it with 0.1-0.15 mol / L lithium hydroxide solution in a molar ratio of 0.5-2:4-6, and hydrothermally at 140-200 ° C The reaction is carried out for 12-48 hours, and then calcined at 350-750° C. for 1-5 hours to obtain the spinel lithium titanate nanosheets.

[0011] A specific method for the application of spinel lithium titanate nanosheets in lithium batteries is: lithium battery assembly: according to the mass ratio of Li 4 Ti 5 O 12 : Polyvinylidene fluoride: Acetylene black = 60-75: 5-10: 15-30 After mixing and grinding, spread evenly on 0.25cm 2 The positive electrode is made of copper sheet, the n...

Embodiment 1

[0014] The specific steps of a preparation method of spinel lithium titanate nanosheets are as follows: mixing 2.0 grams of titanium dioxide powder with 40 milliliters of potassium hydroxide solution with a concentration of 20 mol / liter, reacting at 160° C. for 96 hours, and then reacting the reactants with dilute hydrochloric acid After washing, 0.1 g of reactant was mixed with 0.15 mol / L lithium hydroxide solution in a molar ratio of 1:5, hydrothermally reacted at 140 ° C for 48 h, and then calcined at 350 ° C for 5 h to obtain the spinel titanic acid. Lithium nanosheets.

[0015] A specific method for the application of spinel lithium titanate nanosheets in lithium batteries is: lithium battery assembly: according to the mass ratio of Li 4 Ti 5 O 12 : Polyvinylidene fluoride: Acetylene black = 75:10:15 Mix and grind and apply evenly to 0.25cm 2 The positive electrode is made of copper sheet, the negative electrode is metal lithium, and the electrolyte is 1M LiClO 4 The ...

Embodiment 2

[0017] The specific steps of a preparation method of spinel lithium titanate nanosheets are as follows: mixing 0.5 g of titanium dioxide powder with 50 ml of potassium hydroxide solution with a concentration of 10 mol / liter, reacting at 200° C. for 48 hours, and then reacting the reactants with dilute hydrochloric acid After washing, 0.5 g of reactant was mixed with 0.1 mol / liter lithium hydroxide solution in a molar ratio of 0.5:4, hydrothermally reacted at 200 ° C for 12 h, and then calcined at 750 ° C for 1 h to obtain the spinel lithium titanate Nanosheets.

[0018] A specific method for the application of spinel lithium titanate nanosheets in lithium batteries is: lithium battery assembly: according to the mass ratio of Li 4 Ti 5 O 12 : Polyvinylidene fluoride: Acetylene black = 70: 5: 25 After mixing and grinding, spread evenly on 0.25cm 2 The positive electrode is made of copper sheet, the negative electrode is metal lithium, and the electrolyte is 1M LiClO 4 The EC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com