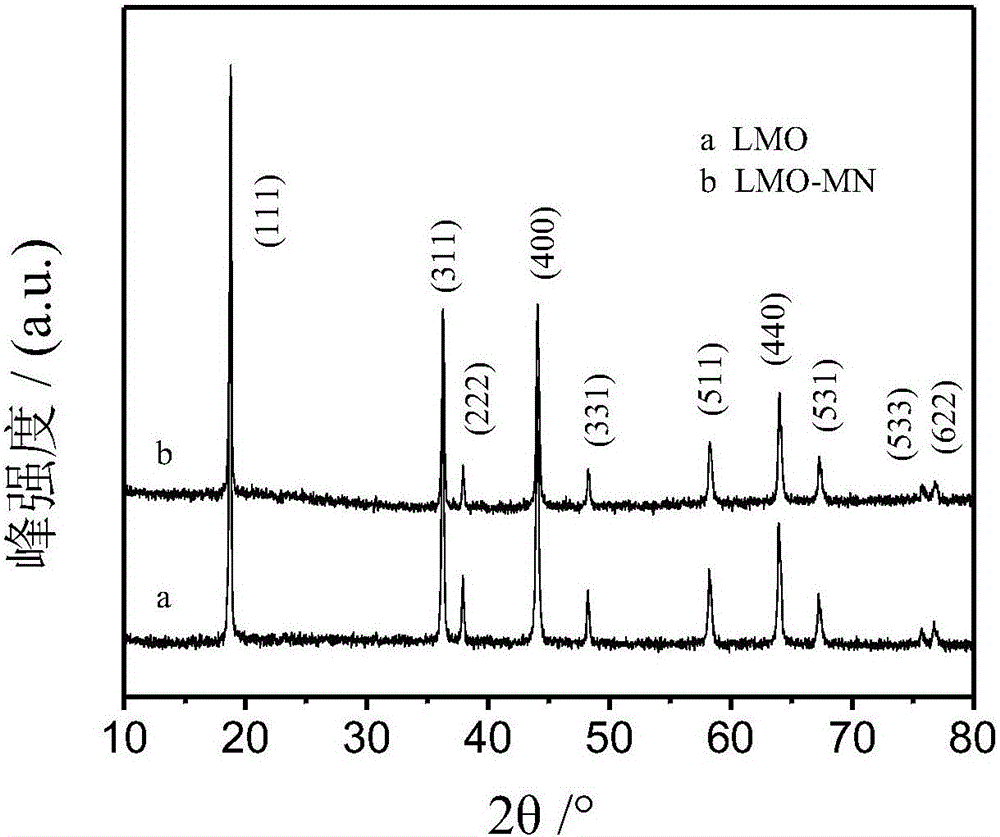

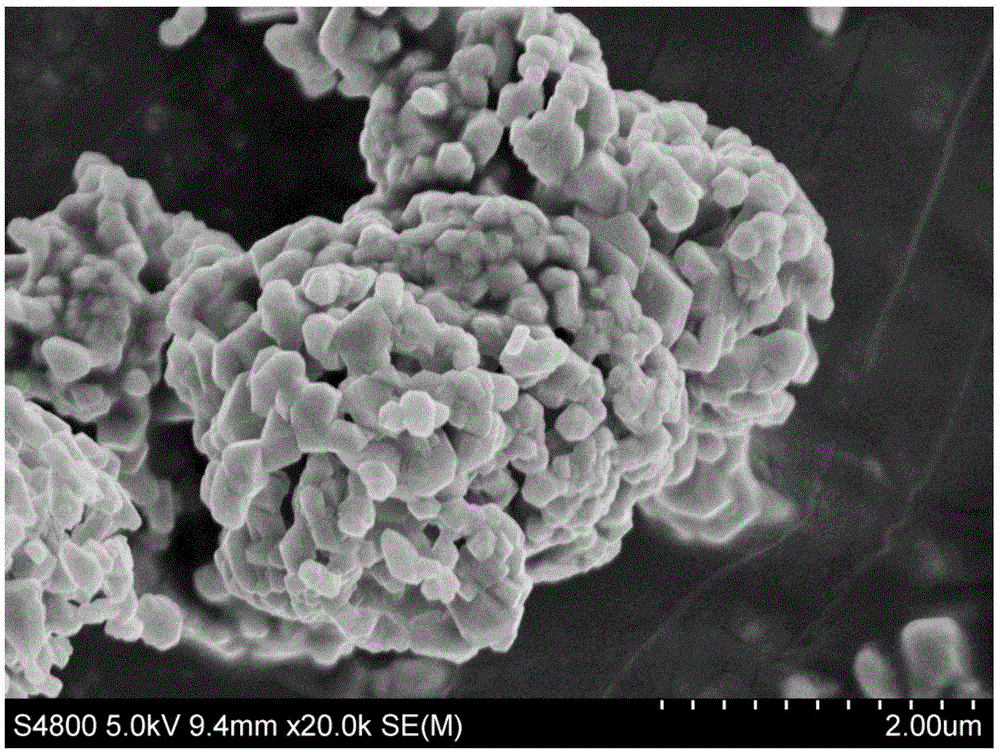

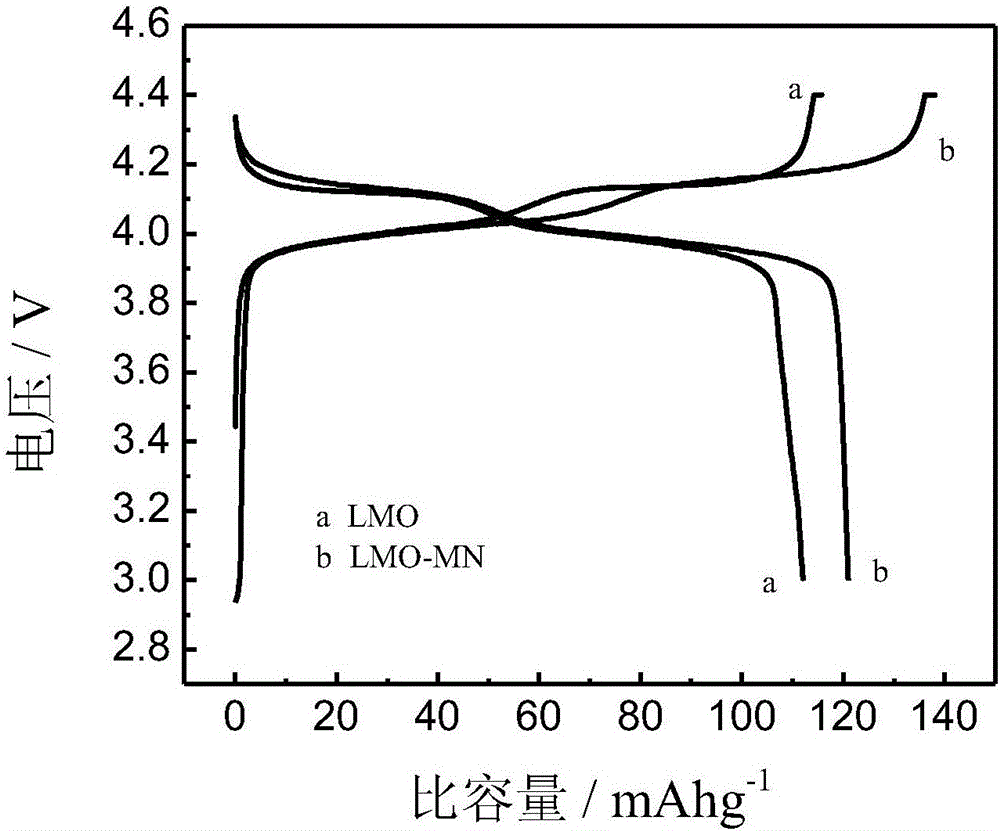

Preparation method capable of increasing electrochemical performance of magnesium-sodium-doped lithium permanganate anode material

A positive electrode material, lithium manganate technology, which is applied in the field of preparation of magnesium and sodium double doping to improve the electrochemical performance of lithium manganate positive electrode material, can solve the problem of three-dimensional diffusion channel blockage of lithium ions, and achieve excellent cycle stability, Broad application prospects and the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Dissolve 0.0357mol of manganese sulfate monohydrate in 250mL of deionized water, and then add 25mL of absolute ethanol dropwise.

[0026] (2) Dissolve 0.357mol ammonium bicarbonate in 250mL deionized water.

[0027] (3) Slowly add the solution obtained in step (2) dropwise into the solution obtained in step (1) for 3 times to obtain a milky white suspension, stir it with a DF-101S heat-collecting magnetic stirrer at 35°C for 1 hour, and age After 3 hours, a pale pink precipitate was obtained; the pale pink precipitate was suction-filtered, washed, and dried in a vacuum oven at 40°C for 8 hours to obtain a pale pink manganese carbonate powder.

[0028] (4) Place the light pink manganese carbonate powder obtained in step (3) in a muffle furnace for pre-sintering at 300°C for 2 hours. After pre-sintering, wash it with hydrochloric acid with a concentration of 0.1 mol / L for 2 days, filter it with suction, and wash it. Send it to 100°C for vacuum drying for 12 hours to ...

Embodiment 2

[0033] (1) Dissolve 0.0357mol of manganese sulfate monohydrate in 250mL of deionized water, and then add 25mL of absolute ethanol dropwise.

[0034] (2) Dissolve 0.357mol ammonium bicarbonate in 250mL deionized water.

[0035] (3) Slowly add the solution obtained in step (2) dropwise into the solution obtained in step (1) for 3 times to obtain a milky white suspension, stir it with a DF-101S heat-collecting magnetic stirrer at 35°C for 1 hour, and age After 3 hours, a pale pink precipitate was obtained; the pale pink precipitate was suction-filtered, washed, and dried in a vacuum oven at 40°C for 8 hours to obtain a pale pink manganese carbonate powder.

[0036] (4) Place the light pink manganese carbonate powder obtained in step (3) in a muffle furnace for pre-sintering at 300°C for 2 hours. After pre-sintering, wash it with hydrochloric acid with a concentration of 0.1 mol / L for 2 days, filter it with suction, and wash it. Send it to 100°C for vacuum drying for 12 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com