Hybrid super capacitor

A supercapacitor and hybrid technology, which is applied in the direction of hybrid capacitor electrolyte, etc., can solve the problems of affecting cycle stability and reducing the energy density of hybrid energy storage devices, and achieve good cycle stability, high energy density, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Preparation of the positive electrode: first make the binder sodium carboxymethyl cellulose into a water dispersion with a mass percentage of 3%, and activate carbon (with a specific surface area of about 2400m 2 / g), acetylene black and sodium carboxymethyl cellulose are mixed in the ratio of 70:10:20 by mass ratio, stir evenly in the high-speed mixer, the gained mixture is evenly coated on the graphite conductive paper surface, moves in the vacuum oven to Take it out after drying, and cut it to get the positive electrode sheet;

[0068] Preparation of electrolyte: Dissolve 10.58g of zinc perchlorate in 100mL of a mixed solution of propylene carbonate, acetonitrile and diethyl carbonate (the volume ratio of the three is 4.5:4.5:1), and prepare a 0.4mol / L solution. get the electrolyte.

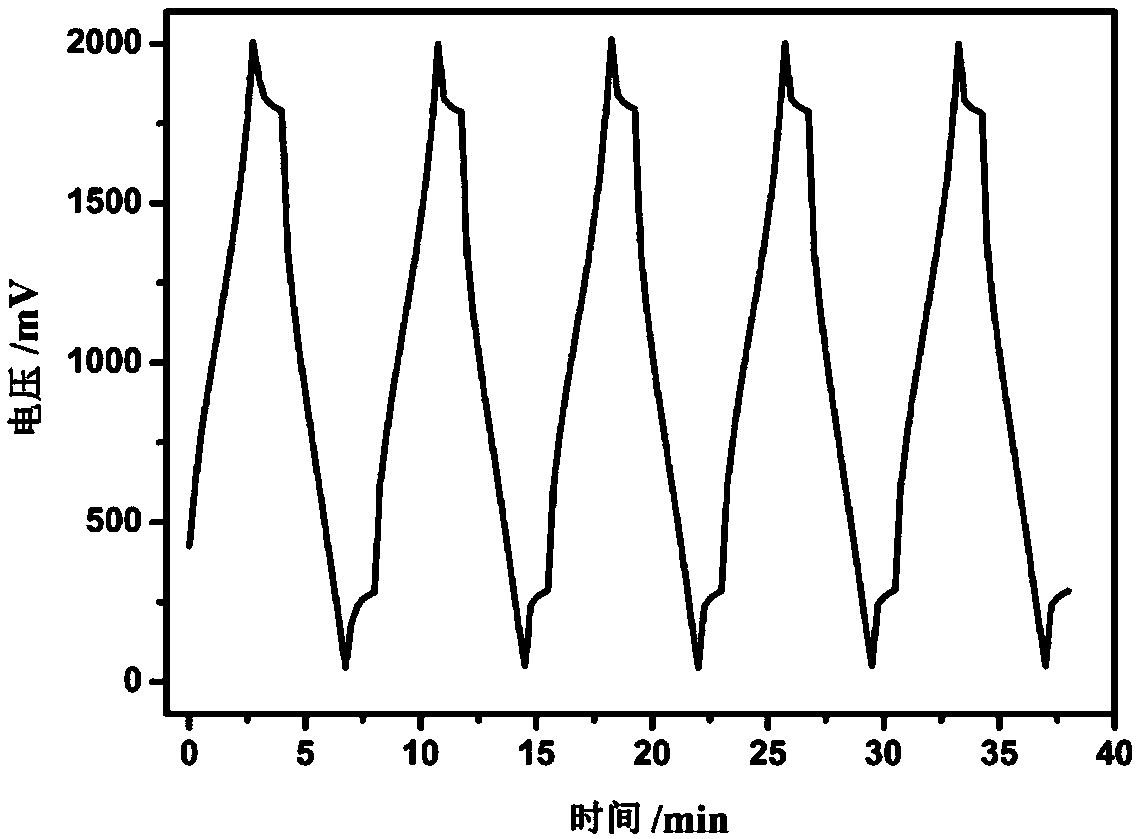

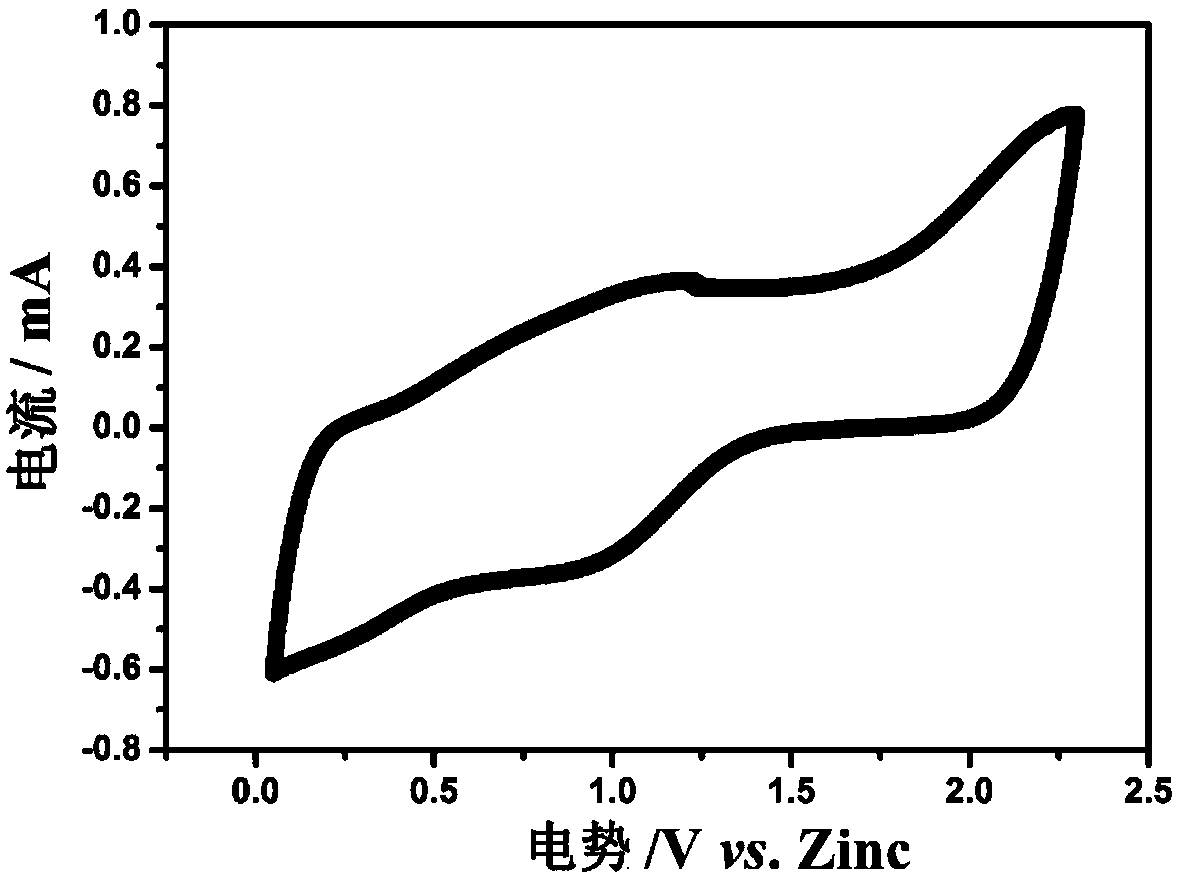

[0069] The prepared positive electrode sheet is used as the positive electrode, the zinc foil is used as the negative electrode, the propylene carbonate / acetonitrile / diethyl carbonat...

Embodiment 2

[0072] Preparation of the positive electrode: First, the binder polyvinylidene fluoride is made into a polyvinylpyrrolidone dispersion liquid with a mass percentage of 5%, and graphene oxide (sheet diameter is 0.3-1 micron), acetylene black and polyvinylidene fluoride are mixed by mass After mixing at a ratio of 70:20:10, stir evenly in a high-speed mixer, and apply the obtained mixture evenly on the surface of the conductive polyethylene film, move it into a vacuum oven until it is dried, take it out, and cut it to obtain the positive electrode sheet;

[0073] Preparation of negative electrode: After mixing zinc powder (about 400 mesh), zinc oxide powder and polyvinylidene fluoride in a mass ratio of 60:30:10, stir evenly in a high-speed mixer, and coat the obtained mixture evenly on brass foil surface, move it into a vacuum oven until it is dried, take it out, and cut it to get the negative electrode sheet;

[0074] Preparation of electrolyte: 5.29g of zinc perchlorate and 5...

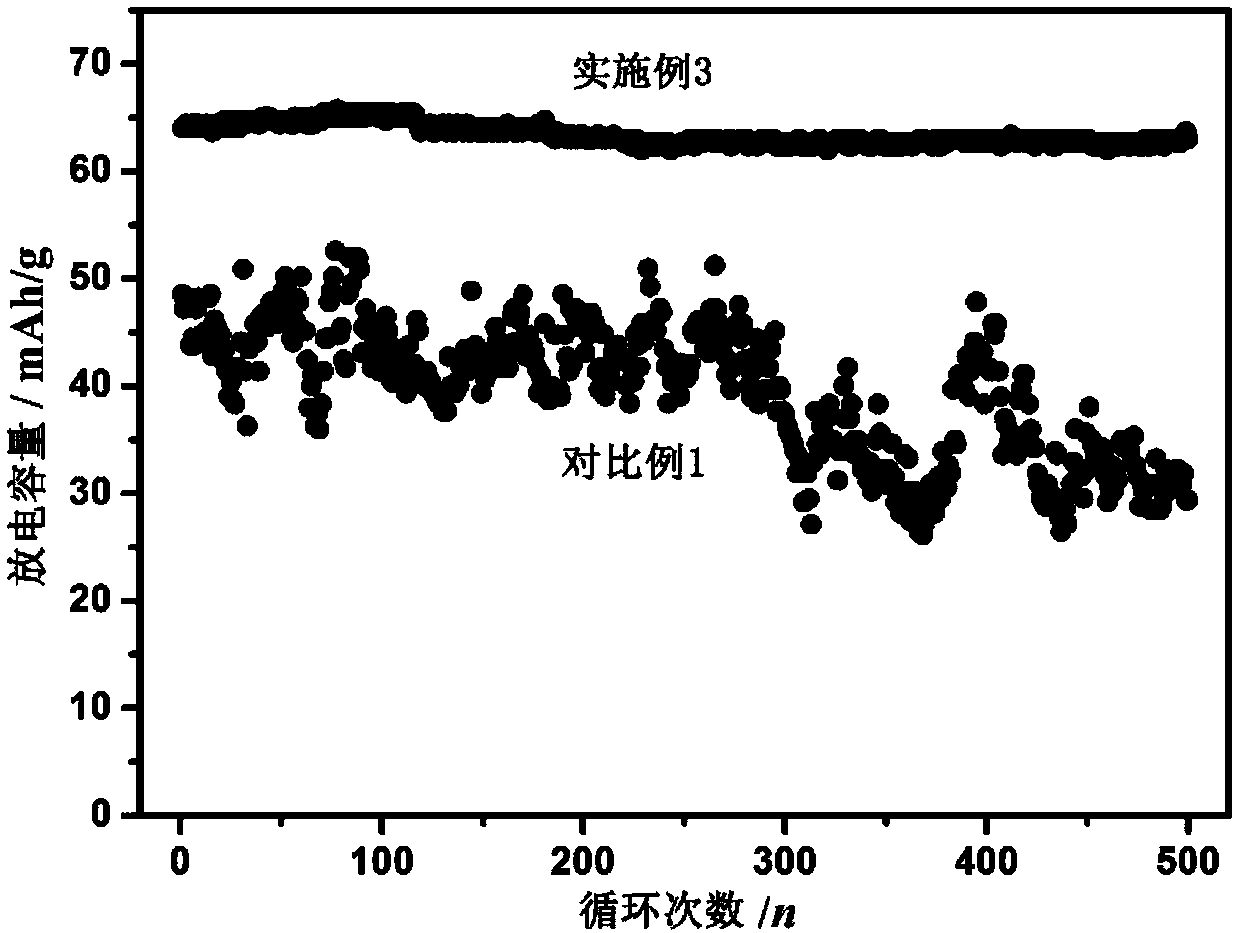

Embodiment 3

[0078] Preparation of the positive electrode: first make the binder sodium carboxymethyl cellulose into a water dispersion with a mass percentage of 3%, and activate carbon (with a specific surface area of about 2400m 2 / g), graphene (approximately 0.3-1 micron in sheet diameter), acetylene black and sodium carboxymethyl cellulose are mixed in a ratio of 78:2:15:5 by mass, and stirred evenly in a high-speed mixer, and the resulting mixture Evenly spread on the surface of titanium foil, move it into a vacuum oven until it is dried, take it out, and cut it to get the positive electrode sheet;

[0079] Preparation of electrolyte solution: Dissolve 18.18g of zinc trifluoromethanesulfonate in 100mL of a mixture of propylene carbonate and N,N-dimethylformamide (the volume ratio of the two is 1:1), and prepare 0.5mol / The solution of L, obtains electrolyte;

[0080] The prepared positive electrode sheet was used as the positive electrode, the zinc foil was used as the negative ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com