Lithium and manganese-rich cathode material of lithium ion battery and preparation method of cathode material

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low initial Coulombic efficiency, large initial irreversible capacity, and poor cycle stability, so as to improve electrochemical performance and suppress irreversible Good chemical reaction and material processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

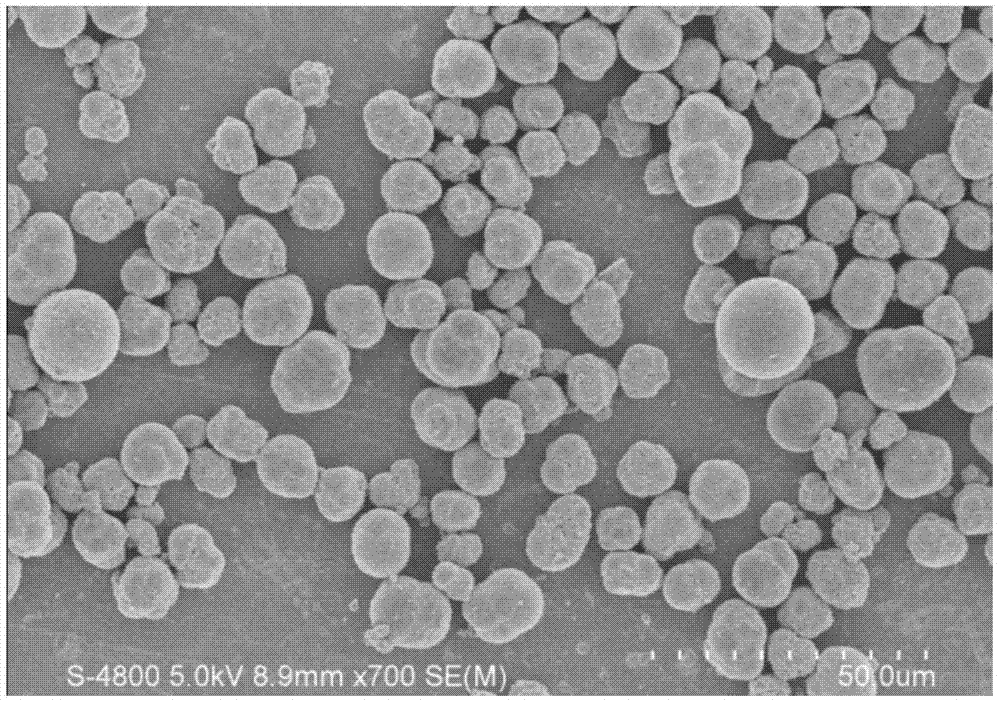

[0040] A preparation method of lithium-rich manganese cathode material for lithium ion battery, the lithium-rich manganese material is Li 2 TiO 3 Coated xLi 2 MnO 3 ·(1-x)LiNi 0.5-a / 2 mn 0.5-a / 2 al a o 2 (wherein, 0.1≤x≤0.9, 0.002≤a≤0.1) materials, the nickel-manganese-aluminum composite carbonate precursor is prepared by the co-precipitation method, and then sintered at high temperature to obtain a spherical or quasi-spherical nickel-manganese-aluminum composite oxide, Adding it into a solvent to disperse evenly, adding tetrabutyl titanate, hydrolyzing to obtain a nickel-manganese-aluminum-titanium compound compound, mixing with a lithium compound, and calcining to obtain a lithium-rich manganese cathode material. in particular:

[0041] Step 1. Preparation of Precursor

[0042] According to xLi 2 MnO 3 ·(1-x)LiNi 0.5-a / 2 mn 0.5-a / 2 al a o 2 In the chemical formula, the stoichiometric ratio of Ni, Mn, and Al is weighed to form a uniform mixed aqueous solution of...

Embodiment 1

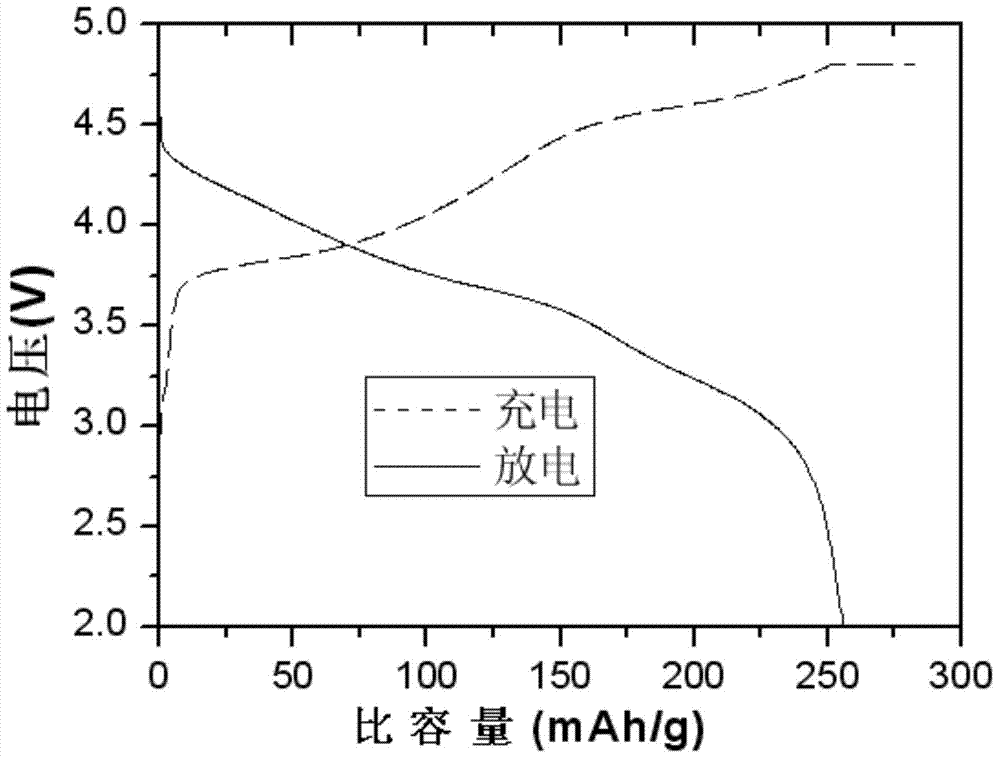

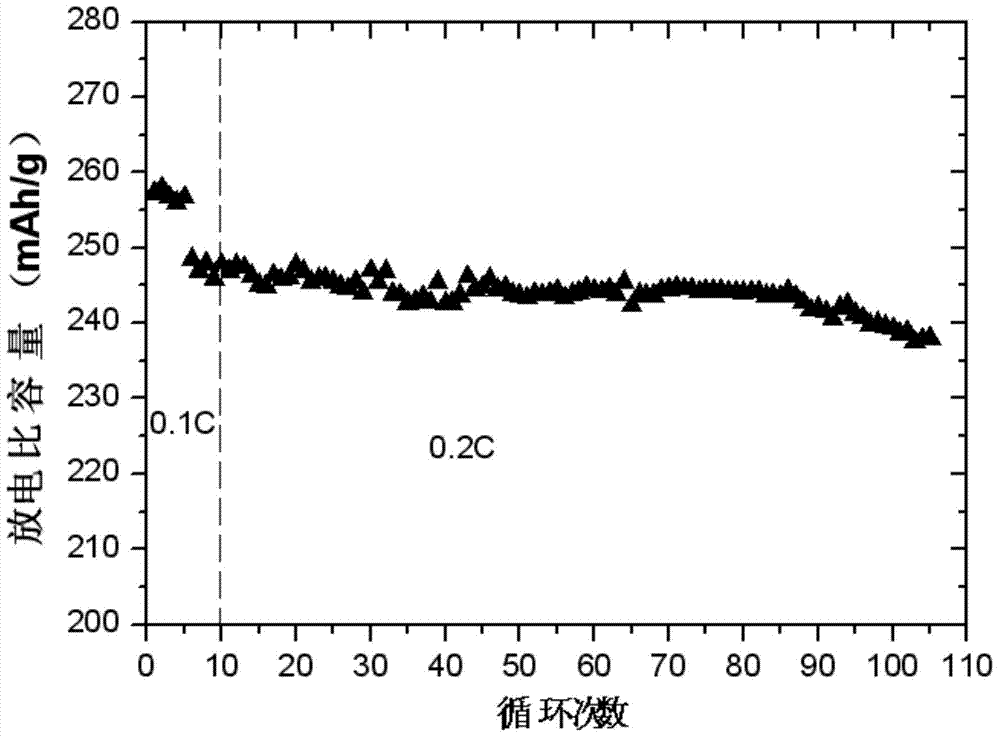

[0048] The present embodiment provides a kind of preparation method of lithium-ion battery lithium-rich manganese cathode material, and this material is Li 2 TiO 3 Coated 0.5Li 2 MnO 3 0.5LiNi 0.485 mn 0.485 al 0.03 o 2 Material, Li 2 TiO 3 Accounting for 3.5% of the total mass of lithium-rich manganese. It includes the following steps.

[0049] Step 1. Preparation of Precursor

[0050] According to 0.5Li 2 MnO 3 0.5LiNi 0.485 mn 0.485 al 0.03 o 2 In the chemical formula, the stoichiometric ratio of Ni, Mn, and Al is weighed to form a uniform mixed aqueous solution of nickel sulfate, manganese nitrate, and aluminum sulfate. The total concentration of metal ions is 0.5mol / L. The temperature of the solution is controlled at a constant temperature of 40°C. Under stirring, Add the precipitating agent lithium carbonate to the mixed solution, the amount of lithium carbonate is the same as the total amount of metal ions, react for 8h, filter, wash, and dry to obtain t...

Embodiment 2

[0062]The present embodiment provides a kind of preparation method of lithium-ion battery lithium-rich manganese cathode material, and this material is Li 2 TiO 3 Coated 0.3Li 2 MnO 3 0.7LiNi 0.47 mn 0.47 al 0.06 o 2 Material, Li 2 TiO 3 Accounting for 0.3% of the total mass of lithium-rich manganese. It includes the following steps.

[0063] Step 1. Preparation of Precursor

[0064] According to 0.3Li 2 MnO 3 0.7LiNi 0.47 mn 0.47 al 0.06 o 2 In the chemical formula, the stoichiometric ratio of Ni, Mn, and Al is weighed to form a uniform mixed aqueous solution of nickel nitrate, manganese nitrate, and aluminum nitrate. The total concentration of metal ions is 2.0mol / L. The temperature of the solution is controlled at a constant temperature of 65°C. Under stirring, Add the precipitating agent lithium carbonate to the mixed solution, the amount of lithium carbonate is the same as the total amount of metal ions, react for 15h, filter, wash and dry to obtain the ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com