Vanadium-lithium phosphate composite material for positive electrode of lithium ion battery and preparation method thereof

A lithium-ion battery and lithium vanadium phosphate technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as high-rate charge and discharge performance of lithium-ion batteries, and achieve safe use and excellent high-rate performance , The effect of high charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Press Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of the raw material Li 2 CO 3 , NH 4 h 2 PO 4 and NH 4 VO 3 Mix, add MWCNTs and PVA accounting for 10% of the total mass of raw materials, the weight ratio of MWCNTs:PVA is 1:1, add 15ml of absolute ethanol and ball mill for 10h on a ball mill, the ball mill speed is set to 350rpm. After the raw material was taken out and dried, it was placed in a tube furnace, and calcined at 850°C for 10 h in an argon atmosphere (gas flow rate of 80 ml / min) to obtain amorphous carbon in situ coated Li 3 V 2 (PO 4 ) 3 The powder formed on the surface (Li 3 V 2 (PO 4 ) 3 / C), containing by mass percentage: 98% Li 3 V 2 (PO 4 ) 3 , 2% carbon.

[0017] The resulting product was analyzed by XRD, showing that they were all Li 3 V 2 (PO 4 ) 3 , there is no impurity phase, the particle size of the product can be obtained by SEM in the range of 200-600nm, and the MWCNTs are evenly distributed among the particles.

[00...

Embodiment 2

[0022] Press Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of the raw material Li 2 CO 3 , NH 4 h 2 PO 4 and NH 4 VO 3 Mix, add MWCNTs and PVA accounting for 20% of the total mass of raw materials, the weight ratio of MWCNTs:PVA is 1:1, add 15ml of absolute ethanol and ball mill for 10h on a ball mill, the ball mill speed is set to 350rpm. The raw materials were taken out and dried, put into a tube furnace, and calcined at 850 °C for 10 h in an argon atmosphere (gas flow rate of 80 ml / min) to obtain MWCNTs-modified Li 3 V 2 (PO 4 ) 3 / C cathode material, containing by mass percentage: 96.5% Li 3 V 2 (PO 4 ) 3 , 3.5% carbon.

[0023] The resulting product was analyzed by XRD, showing that they were all Li 3 V 2 (PO 4 ) 3 , there is no impurity phase, the particle size of the product can be obtained by SEM in the range of 200-600nm, and the MWCNTs are evenly distributed among the particles.

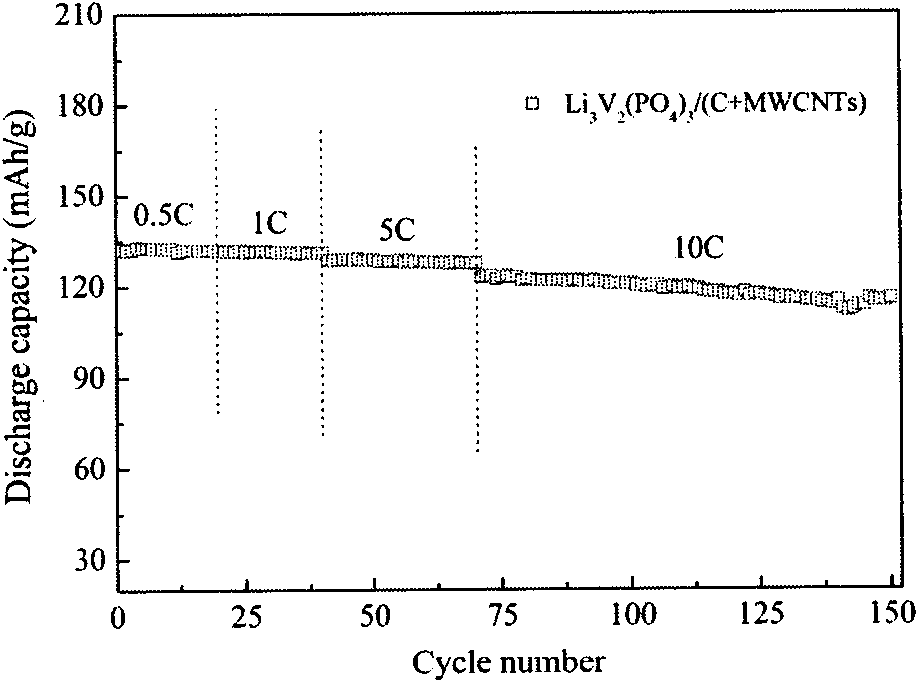

[0024] The prepared MWCNTs modified Li 3 V 2 (PO 4 ) 3 / C The po...

Embodiment 3

[0028] Press Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of the raw material Li 2 CO 3 , NH 4 h 2 PO 4 and NH 4 VO 3 Mix, add MWCNTs and PVA accounting for 30% of the total mass of raw materials, the weight ratio of MWCNTs:PVA is 1:1, add 15ml of absolute ethanol and ball mill for 10h on a ball mill, the speed of the ball mill is set to 350rpm. The raw materials were taken out and dried, put into a tube furnace, and calcined at 850 °C for 10 h in an argon atmosphere (gas flow rate of 80 ml / min) to obtain MWCNTs-modified Li 3 V 2 (PO 4 ) 3 / C cathode material, containing by mass percentage: 95% Li 3 V 2 (PO 4 ) 3 , 5% carbon.

[0029] The resulting product was analyzed by XRD, showing that they were all Li 3 V 2 (PO 4 ) 3 , there is no impurity phase, the particle size of the product can be obtained by SEM in the range of 200-600nm, and the MWCNTs are evenly distributed among the particles.

[0030] The prepared MWCNTs modified Li 3 V 2 (PO 4 ) 3 / C po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Electronic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com