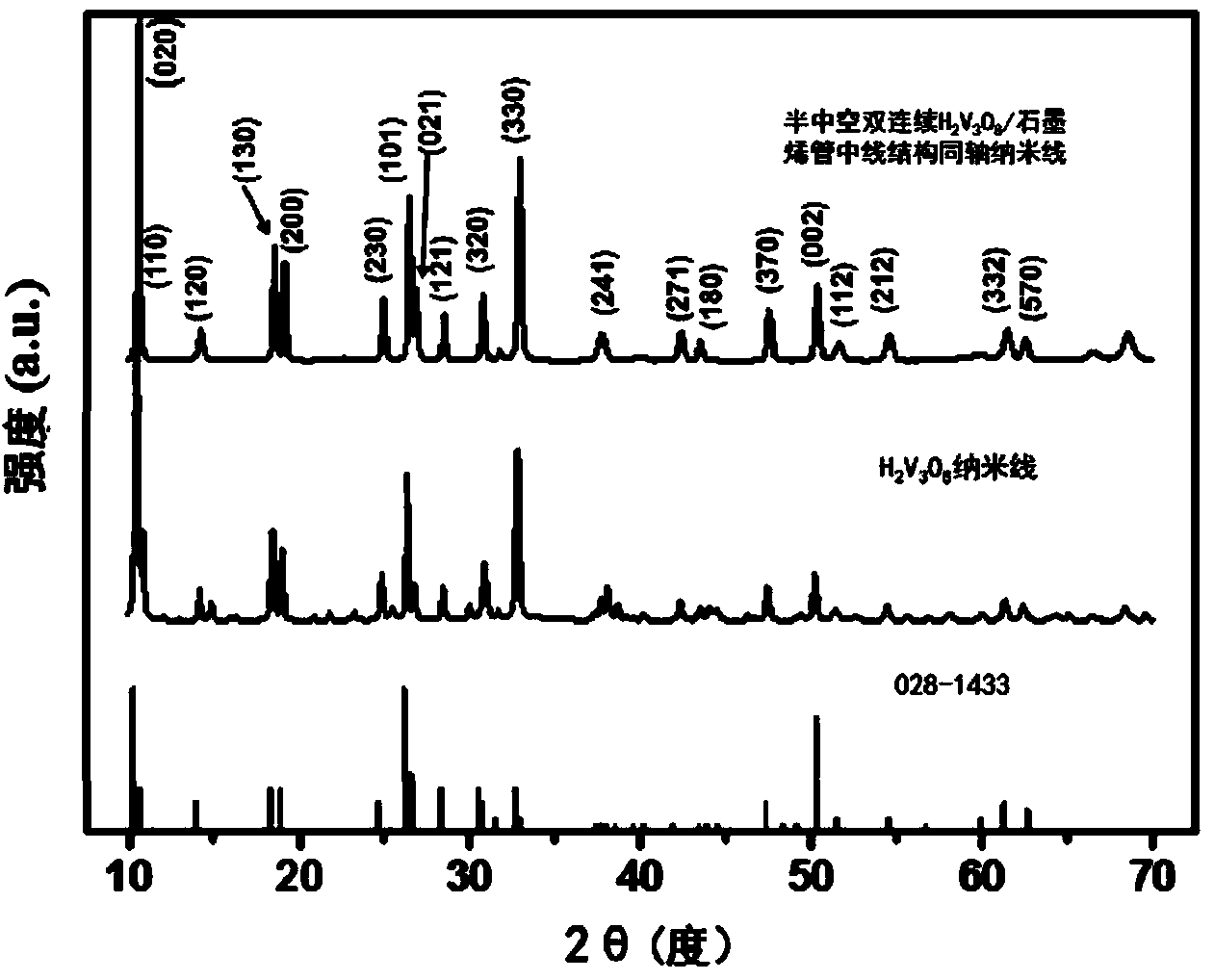

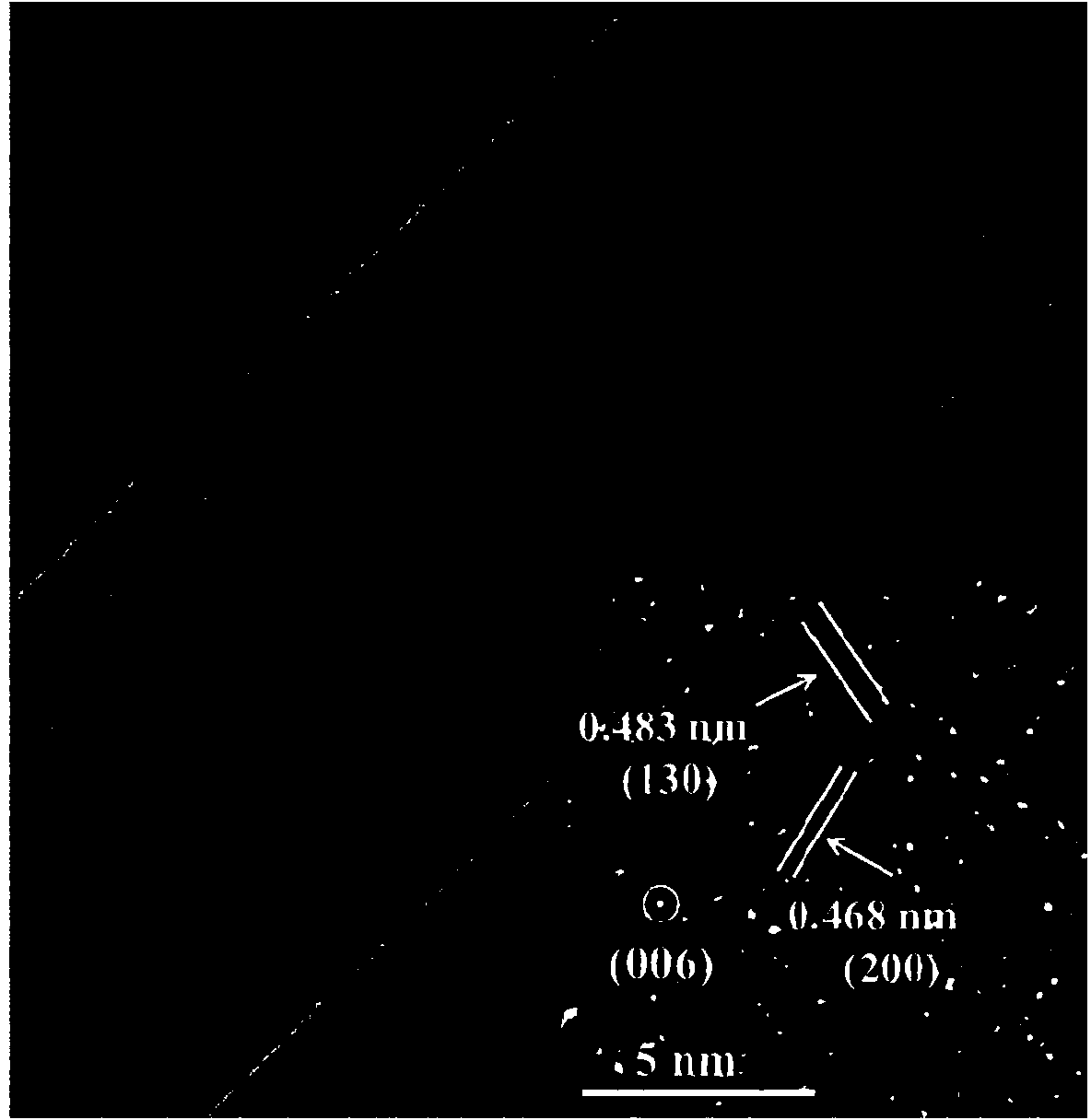

Semi-hollow bicontinuous line-structure coaxial nanowire material in H2V3O8/graphene tube, as well as preparation method and application of material

A graphene tube, bicontinuous technology, applied in the fields of nanomaterials and electrochemistry, to achieve the effects of being conducive to market promotion, excellent electrochemical performance, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Semi-hollow double continuous H 2 V 3 o 8 The preparation method of coaxial nanowire material with wire structure in graphene tube, it comprises the steps:

[0051] One, the preparation of graphene dispersion liquid:

[0052] 1) Measure 1g of graphite powder and 23ml of concentrated sulfuric acid into a 250ml Erlenmeyer flask, and stir gently with a magnetic stirrer for 24 hours at room temperature;

[0053] 2) Turn on the constant temperature water bath and adjust the temperature of the water bath to 40°C. After the temperature is stable, put the Erlenmeyer flask into the water bath and stir for 5 minutes. Measure 100mg NaNO 3 Add to the dispersion obtained in step a), and stir for 5 minutes. Then measure 500mgKMnO 4 Slowly add the powder into the conical flask, keep the temperature of the dispersion below 45°C, and stir for 30 minutes;

[0054] 3) To the dispersion obtained in step b), add deionized water three times, add 3ml deionized water for the first two t...

Embodiment 2

[0074] One, the preparation of graphene dispersion liquid: same as embodiment 1;

[0075] Two, V 2 o 5 Preparation of sol: same as Example 1;

[0076] 3. V 2 o 5 Preparation of quantum dots / graphene composites:

[0077] 9) Take 1.1mmol of V 2 o 5 The sol is placed in a beaker, with aniline / V 2 o 5 Sol molar ratio is 0.03:1 ratio to V 2 o 5 Add 0.5mol / L aniline solution to the sol, and stir evenly;

[0078] 10) Add 16ml of graphene dispersion to the solution obtained in step 9), and add deionized water until the total volume of the solution is 60ml, and stir for 30 minutes;

[0079] 11) Sonicate the solution obtained in step 10) for 20 minutes to obtain a homogeneous solution;

[0080] 12) Transfer the homogeneous solution obtained in step 11) to a 100ml reactor, put it in a thermostat at 200°C for hydrothermal reaction, and the reaction time is 84 hours. After the reaction, take it out of the reactor and let it cool down to room temperature naturally;

[0081] 13)...

Embodiment 3

[0084] One, the preparation of graphene dispersion liquid: same as embodiment 1;

[0085] Two, V 2 o 5 Preparation of sol: same as Example 1;

[0086] 3. V 2 o 5 Preparation of quantum dots / graphene composites:

[0087] 9) Take 1.5mmol of V 2 o 5 The sol is placed in a beaker, with aniline / V 2 o 5 Sol molar ratio is 0.03:1 ratio to V 2 o 5 Add 0.5mol / L aniline solution to the sol, and stir evenly;

[0088] 10) Add 10ml of graphene dispersion to the solution obtained in step 9), and add deionized water until the total volume of the solution is 60ml, and stir for 30 minutes;

[0089] 11) Sonicate the solution obtained in step 10) for 20 minutes to obtain a homogeneous solution;

[0090] 12) Transfer the homogeneous solution obtained in step 11) to a 100ml reactor, and put it in a thermostat at 160°C for hydrothermal reaction. The reaction time is 12 hours. After the reaction, take it out of the reactor and cool it down to room temperature naturally;

[0091] 13) The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com