Nitrogen-doped hollow carbon sphere composite and preparation method and application thereof

A technology of composite materials and hollow carbon spheres, applied in active material electrodes, electrical components, electrochemical generators, etc., can solve the problem of low capacitance, achieve low cost, simple polymerization method, and promote development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Dissolve 1 mmol of manganese acetate and 10 mmol of ammonium bicarbonate in 30 mL of ethylene glycol solution, perform hydrothermal reaction at 180° C. for 12 h, cool to normal temperature, then centrifuge, wash, and dry to obtain manganese carbonate microspheres.

[0039] (2) 100 mg of manganese carbonate microspheres and 100 mg of dopamine hydrochloride were dissolved in a Tris buffer solution with pH ≈ 8.5, reacted at room temperature, and then the reaction product was separated from solid to liquid, washed and dried to obtain a manganese carbonate / polydopamine complex.

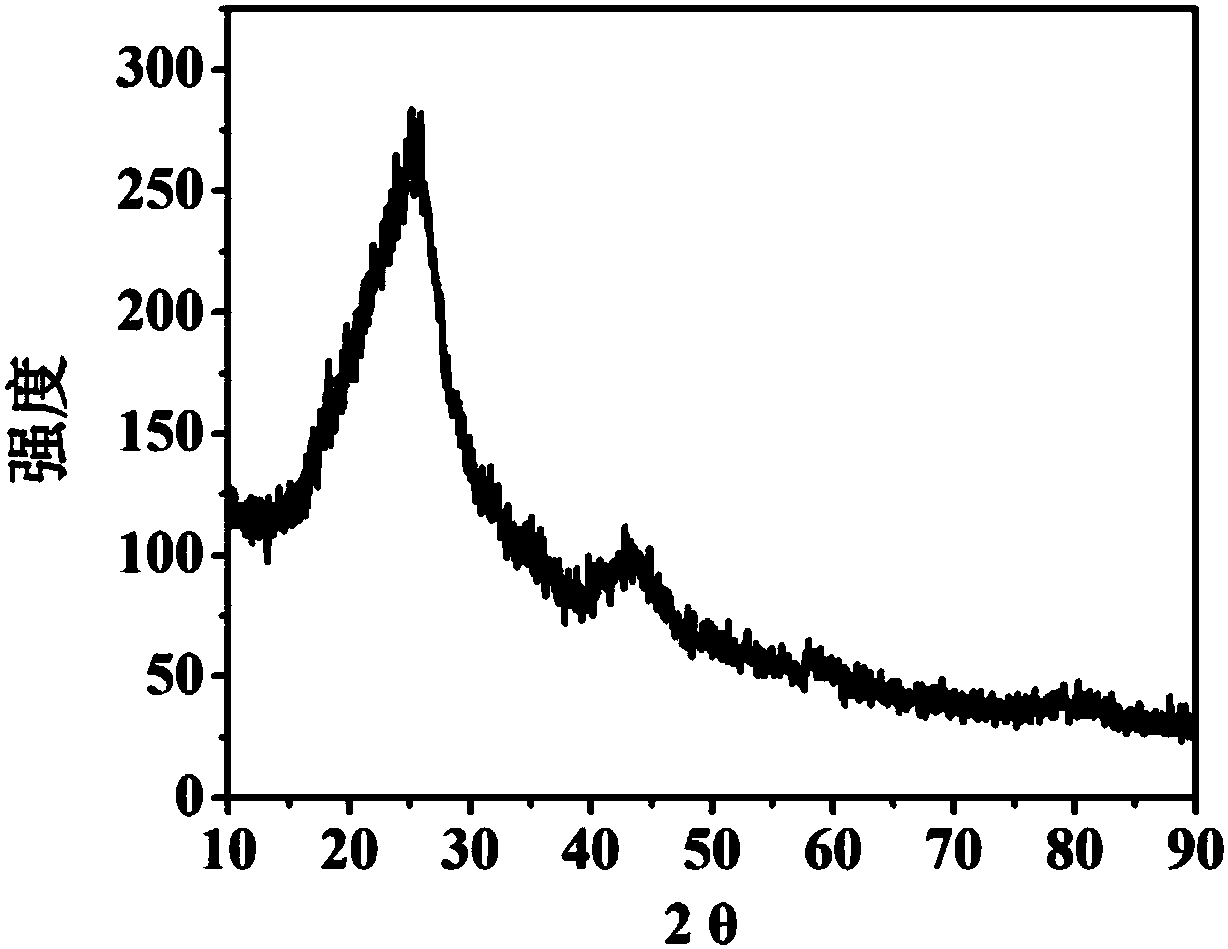

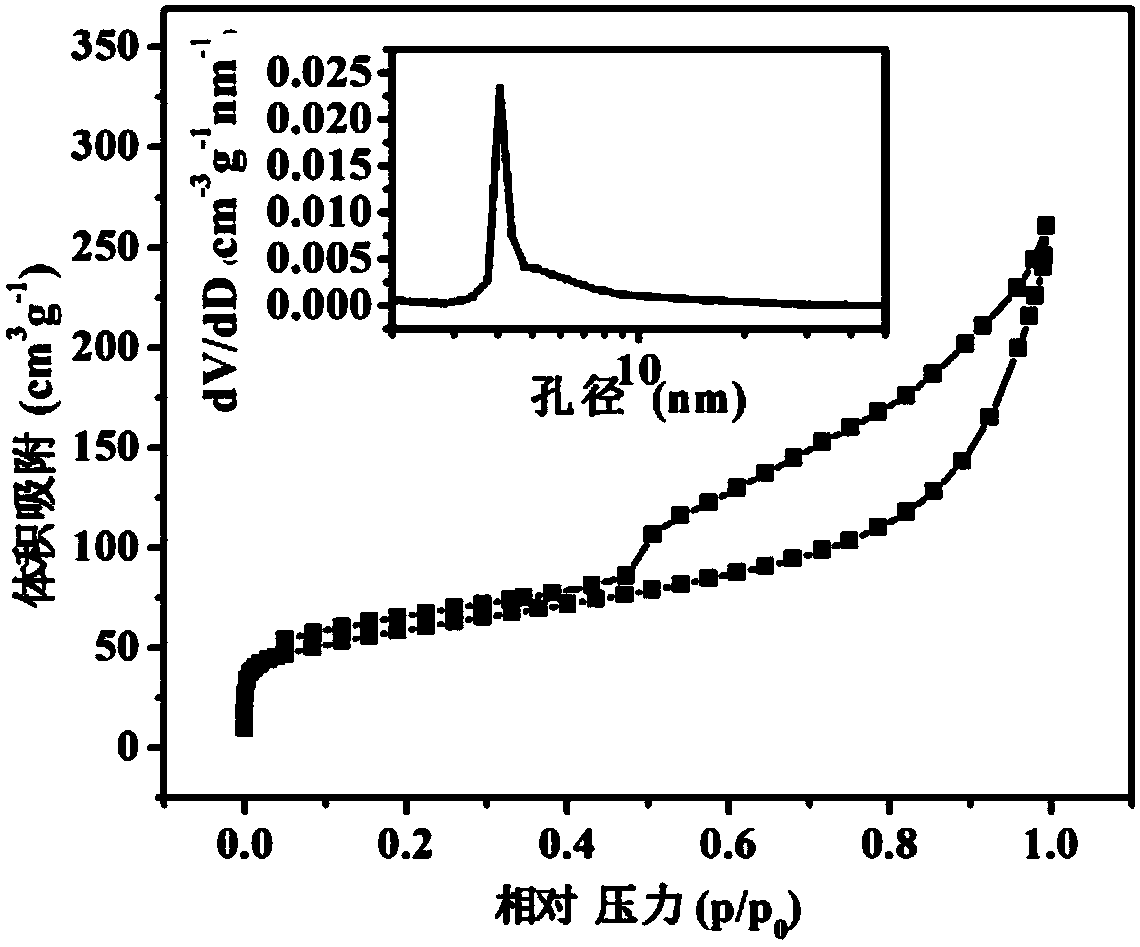

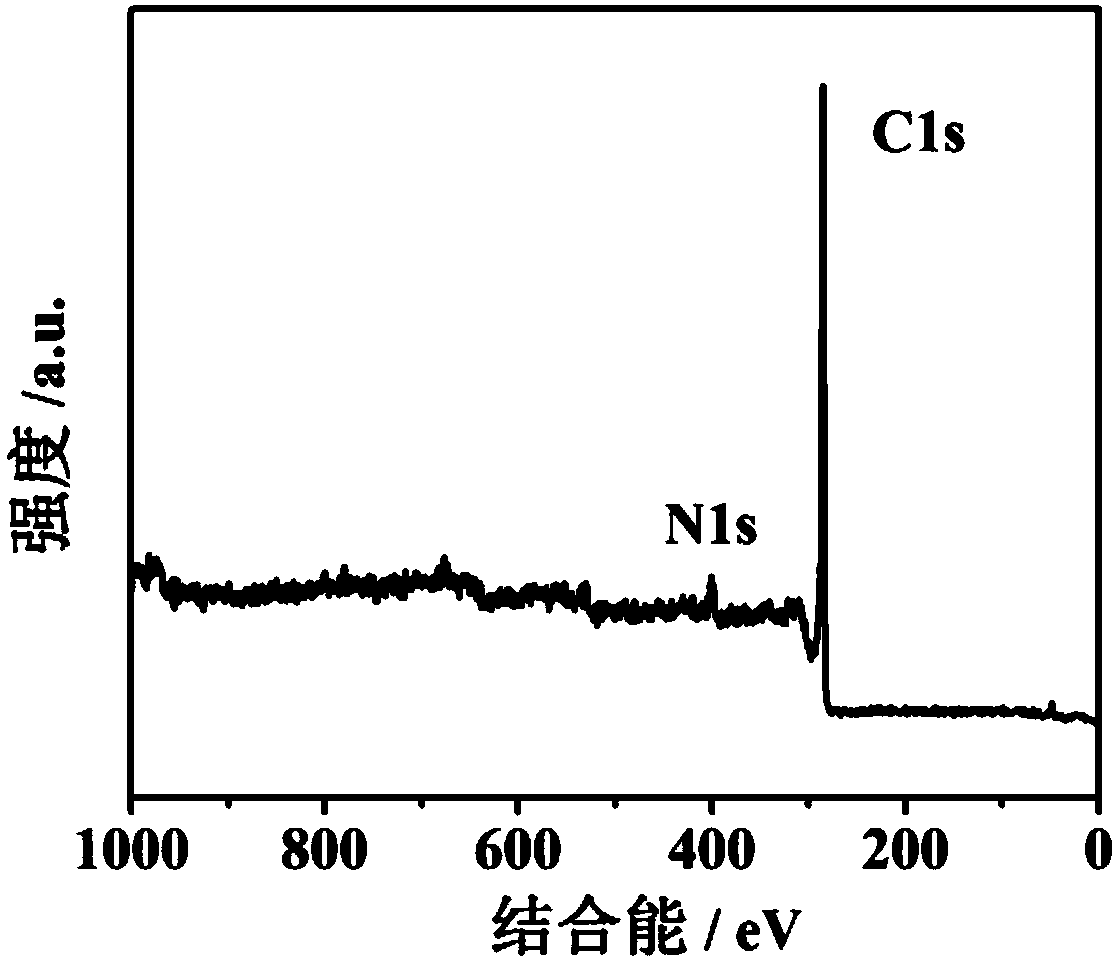

[0040] (3) Under the protection of nitrogen, the manganese carbonate / polydopamine composite was calcined at 700°C for 5h, then cooled to 500°C, and the reaction was continued for 2h to obtain nitrogen-doped carbon-coated manganese oxide particles.

[0041] (4) Nitrogen-doped carbon-coated manganese oxide particles were treated with 0.5 mol / L sulfuric acid for 24 hours, centrifuged with absolute e...

Embodiment 2

[0046] (1) Dissolve 1mmol of manganese acetate and 12mmol of ammonium bicarbonate in 30mL of ethylene glycol solution, perform hydrothermal reaction at 200°C for 24h, cool to normal temperature, then centrifuge, wash and dry to obtain manganese carbonate microspheres.

[0047] (2) 100 mg of manganese carbonate microspheres and 300 mg of dopamine hydrochloride were dissolved in a Tris buffer solution with pH ≈ 8.5, reacted at room temperature, and then the reaction product was separated from solid to liquid, washed and dried to obtain a manganese carbonate / polydopamine complex.

[0048] (3) Under the protection of nitrogen, the manganese carbonate / polydopamine composite was calcined at 800°C for 8h, then cooled to 400°C, and the reaction was continued for 3h to obtain nitrogen-doped carbon-coated manganese oxide particles.

[0049] (4) Nitrogen-doped carbon-coated manganese oxide particles were treated with 0.1 mol / L hydrochloric acid for 24 hours, centrifuged with absolute etha...

Embodiment 3

[0052] (1) Dissolve 1mmol of manganese acetate and 8mmol of ammonium bicarbonate in 30mL of ethylene glycol solution, perform hydrothermal reaction at 220°C for 12h, cool to room temperature, then centrifuge, wash and dry to obtain manganese carbonate microspheres.

[0053] (2) 100 mg of manganese carbonate microspheres and 200 mg of dopamine hydrochloride were dissolved in a Tris buffer solution with pH ≈ 8.5, reacted at room temperature, and then the reaction product was separated from solid to liquid, washed and dried to obtain a manganese carbonate / polydopamine complex.

[0054] (3) Under the protection of nitrogen, the manganese carbonate / polydopamine composite was calcined at 700°C for 6h, then cooled to 500°C, and the reaction was continued for 3h to obtain nitrogen-doped carbon-coated manganese oxide particles.

[0055] (4) Nitrogen-doped carbon-coated manganese oxide particles were treated with 1mol / L oxalic acid for 48 hours, centrifuged with absolute ethanol, and dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com