Iron based metal organic framework compound / graphene composite and application thereof

An organic framework and iron-based metal technology, applied in the field of lithium-ion battery energy, can solve the problems of unsatisfactory fast charging and discharging, limited lithium ion deintercalation efficiency, long activation time, etc., and achieve low raw material prices and good cycle stability , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

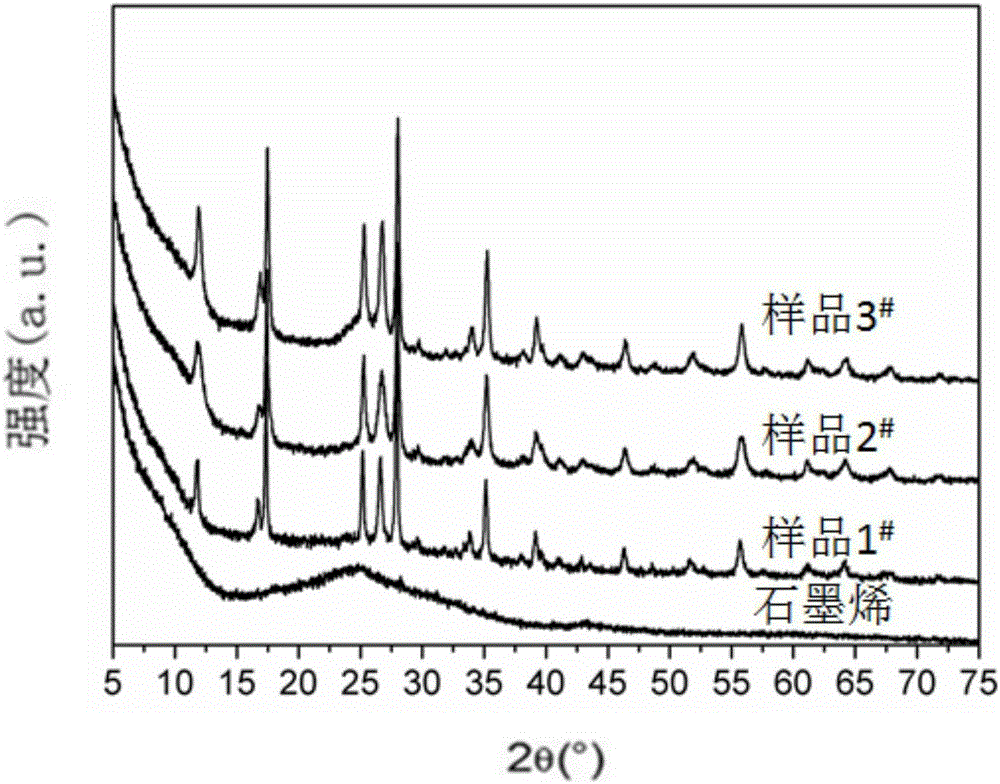

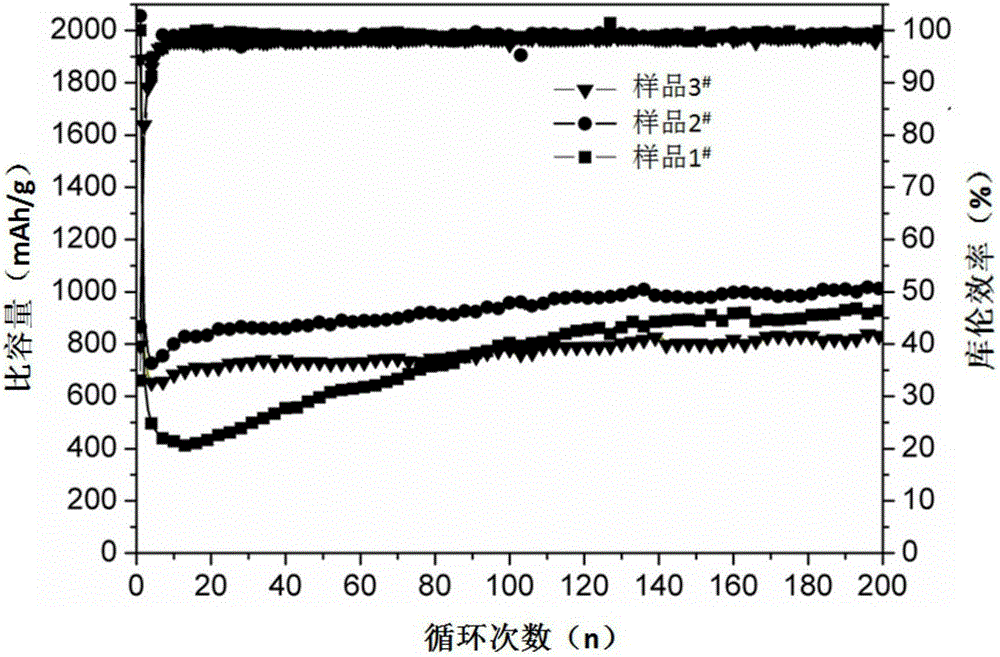

[0034] Example 1 Sample 1 # and battery C1 # preparation of

[0035] sample 1 # Preparation of:

[0036] Add DMF (N,N-dimethylformamide) 60mL in the beaker, C 8 h 6 o 4 (terephthalic acid) 0.230g, FeCl 3 .6H 2 O (ferric chloride hexahydrate) 0.374g, anhydrous acetic acid 0.415g, and fully stirred, then transferred to a 100mL reaction kettle, placed in a blast drying oven at 150°C for 2h, and then separated Dry to obtain the iron-based metal-organic framework compound, which is designated as sample 1 # .

[0037] battery C1 # preparation of :

[0038] Weigh 0.0757g sample 1 # Put into the agate mortar, after grinding for 5 minutes, weigh 0.0223g of carbon black into the agate mortar, continue grinding for 10 minutes, then add 0.0124g of polyvinylidene fluoride binder (abbreviated as PVDF binder) , continue to grind for 40 minutes, then transfer to a 25mL glass bottle, add 2mL of N-methylpyrrolidone solution dropwise, place it in a magnetic stirrer and con...

Embodiment 2

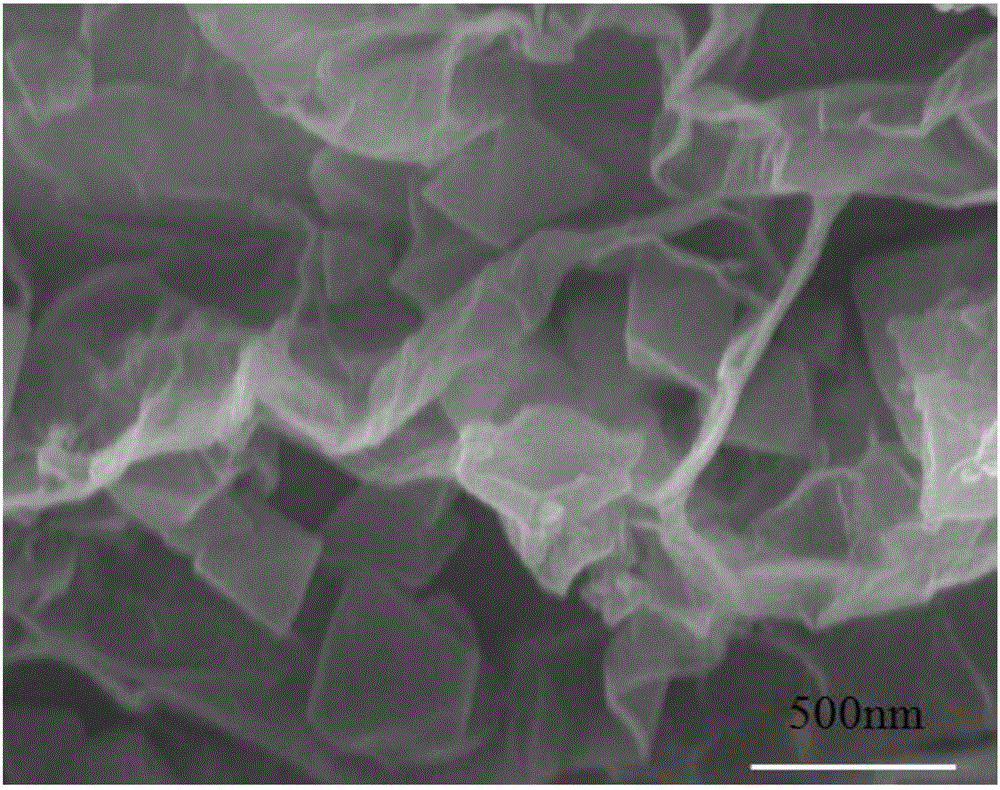

[0039] Example 2 Sample 2 # and battery C2 # preparation of

[0040] sample 2 # Preparation of:

[0041] Take 30.4 mg of graphene in a glass beaker, and add 60 mL of DMF (N, N-dimethylformamide) to the beaker, and ultrasonically vibrate for 60 min to disperse it evenly; then add C 8 h 6 o 4 (terephthalic acid) 0.230g, FeCl 3 .6H 2 O (ferric chloride hexahydrate) 0.374g, anhydrous acetic acid 0.415g, and fully stirred, then transferred to a 100mL reaction kettle, placed in a blast drying oven at 150°C for 2h, and then separated Dry to obtain the iron-based metal-organic framework compound / graphene composite material, which is designated as sample 2 # . sample 2 # The weight percent content of graphene in the middle is 5wt%.

[0042] battery C2 # preparation of :

[0043] Weigh 0.0757g sample 2 # Put into the agate mortar, after grinding for 5 minutes, weigh 0.0223g of carbon black into the agate mortar, continue grinding for 10 minutes, then add 0.0124...

Embodiment 3

[0044] Example 3 Sample 3 # and battery C3 # preparation of

[0045] sample 3 # Preparation of:

[0046] Get 60.8mg of graphene in a glass beaker, and add DMF (N, N-dimethylformamide) 60mL in the beaker, ultrasonic vibration 60min, make it disperse evenly; Then add C 8 h 6 o 4 (terephthalic acid) 0.230g, FeCl 3 .6H 2 O (ferric chloride hexahydrate) 0.374g, anhydrous acetic acid 0.415g, and fully stirred, then transferred to a 100mL reaction kettle, placed in a blast drying oven at 150°C for 2h, and then separated Dry to obtain the iron-based metal-organic framework compound / graphene composite material, which is designated as sample 3 # . sample 3 # The weight percent content of graphene in the middle is 10wt%.

[0047] battery C3 # preparation of :

[0048] Weigh 0.0785g sample 3 # Put into the agate mortar and grind for 5 minutes, weigh 0.0224g of carbon black and add it into the agate mortar, continue grinding for 10 minutes, then add 0.0122g of pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com