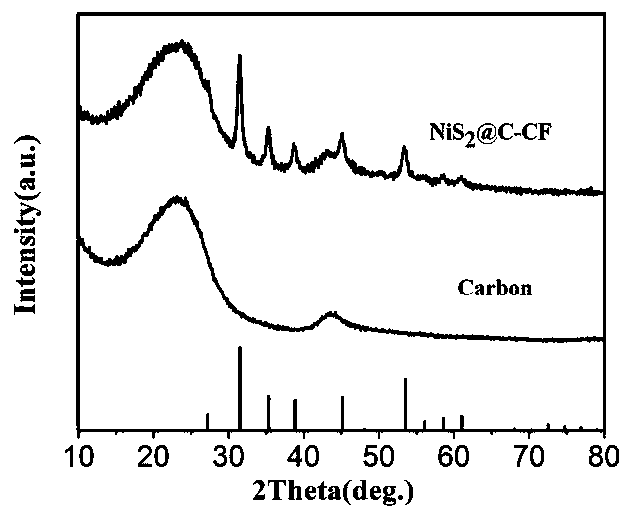

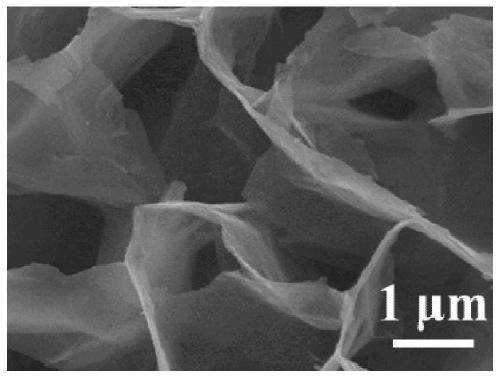

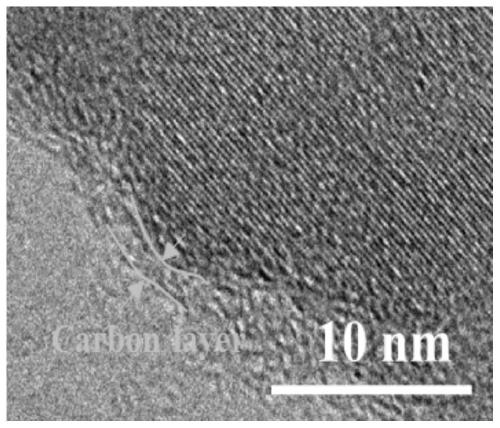

Carbon cloth-loaded carbon-coated nickel disulfide nanosheet composite material and preparation method and application thereof

A composite material, nickel disulfide technology, applied in the field of nanomaterials and electrochemistry, to achieve good cycle performance, good capacity retention, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the carbon-coated nickel disulfide nanosheet composite material supported by carbon cloth, it comprises the steps:

[0031] 1) Take 0.9 g of nickel nitrate hexahydrate and 0.56 g of hexamethylenetetramine, dissolve them in 80 ml of deionized water, and stir until completely dissolved.

[0032] 2) Put the carbon cloth into the solution obtained in step 1), and conduct a hydrothermal reaction at 100° C. for 10 h.

[0033] 3) Wash and dry the product obtained in step 2) to obtain the precursor (Ni(OH) 2 -CF).

[0034] 4) Aniline: tartaric acid: the precursor (Ni(OH) calculated in step 3) 2 -CF) was dissolved in 150ml of deionized water at a molar ratio of 3:5:3, and ultrasonicated in an ice-water bath for 30 minutes.

[0035] 5) In the solution obtained in step 4), add 0.2mol L of pre-cooled in ice water -1 Ammonium persulfate aqueous solution 50ml, the system was placed in ice-water bath for 6h.

[0036] 6) Wash the product obtained in step ...

Embodiment 2

[0041] 1) Take 2.3 g of nickel nitrate hexahydrate and 1.4 g of hexamethylenetetramine, dissolve them in 80 ml of deionized water, and stir until completely dissolved.

[0042] 2) Put the carbon cloth into the solution obtained in step 1), and conduct a hydrothermal reaction at 100° C. for 10 h.

[0043] 3) Wash the product obtained in step 2) and dry it to obtain the precursor (Ni(OH) 2 -CF).

[0044] 4) Aniline: tartaric acid: the precursor (Ni(OH) calculated in step 3) 2 -CF) was dissolved in 150ml of deionized water at a molar ratio of 3:5:3, and ultrasonicated in an ice-water bath for 30 minutes.

[0045] 5) In the solution obtained in step 4), add 0.2mol L of pre-cooled in ice water -1 Ammonium persulfate aqueous solution 50ml, the system was placed in ice-water bath for 6h.

[0046] 6) Wash the product obtained in step 5) with deionized water, and dry it in a vacuum oven at 60°C to obtain a polyaniline-coated nickel precursor composite material (Ni(OH) 2 @PANI-CF);...

Embodiment 3

[0050] 1) Take 0.9 g of nickel nitrate hexahydrate and 0.56 g of hexamethylenetetramine, dissolve them in 80 ml of deionized water, and stir until completely dissolved.

[0051] 2) Put the carbon cloth into the solution obtained in step 1), and conduct a hydrothermal reaction at 100° C. for 10 h.

[0052] 3) Wash and dry the product obtained in step 2) to obtain the precursor (Ni(OH) 2 -CF).

[0053] 4) Aniline: tartaric acid: the precursor (Ni(OH) calculated in step 3) 2 -CF) was dissolved in 150ml of deionized water at a molar ratio of 6:5:3, and ultrasonicated in an ice-water bath for 30 minutes.

[0054] 5) In the solution obtained in step 4), add 0.2mol L of pre-cooled in ice water -1 Ammonium persulfate aqueous solution 50ml, the system was placed in ice-water bath for 6h.

[0055] 6) Wash the product obtained in step 5) with deionized water, and dry it in a vacuum oven at 60°C to obtain a polyaniline-coated nickel precursor composite material (Ni(OH) 2 @PANI-CF); ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com