Method for preparing tin-carbon composite negative electrode material

A negative electrode material, tin-carbon technology, is applied in the preparation of tin-carbon composite materials. The application field of tin-carbon composite materials in the battery industry can solve the problems of low initial charge and discharge efficiency of tin-carbon composite materials and complex ball milling equipment, etc. High capacity, simple process, good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

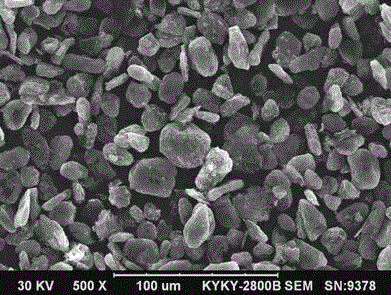

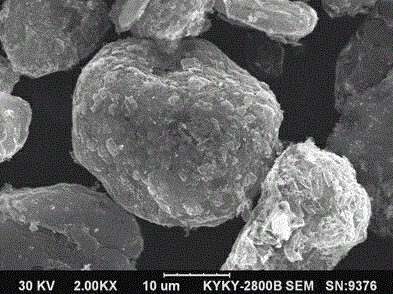

[0022] The preparation method process of the present invention is as follows:

[0023] Weigh tin and graphite according to the mass ratio of 0.03 ~ 0.8 : 1, tin is introduced by tin-containing compounds, ball mill in a ball mill jar for 1 ~ 100 h, the mass of the ball and graphite material is 0.2 ~ 10 : 1, and then add One or more of sodium hydroxide, potassium hydroxide, calcium hydroxide, sodium carbonate, potassium carbonate, and urea are used as solid alkaline substances. The molar ratio of tin to solid alkali substances is 0.6 to 1: 1, and the ball mill is 1~ 100 h; then add organic carbon source and carry out ball milling mixing, the mass ratio of organic carbon source and graphite is 0.01 ~ 0.2: 1, preferably 0.02 ~ 0.06: 1; described organic carbon source is pitch, phenolic resin, epoxy resin , polyacrylamide resin, polyvinylidene fluoride, polyoxyethylene-polyoxypropylene-polyoxyethylene, etc.; the resulting mixture is sintered in a muffle furnace at 600-1100 ° C, and...

Embodiment 1

[0026] Put 45 g of graphite and 1 g of stannous chloride into a ball mill jar and mill for 30 minutes at a speed of 300 rpm, wherein the mass of the ball is 500 g. After they are mixed evenly, add 0.6 g of anhydrous sodium carbonate for ball milling for 5 hours, then add 2.0 g of pitch was recoated, and after ball milling for 1 h, the mixture was fired at 800 °C for 5 h in a nitrogen atmosphere to obtain a tin-carbon composite material precursor. The tin-carbon composite material precursor was washed and filtered, and dried overnight at 85 °C to obtain a tin-carbon composite negative electrode material, which was designated as sample 1.

[0027] The above-prepared tin-carbon composite material is the positive electrode, the lithium sheet is the negative electrode, and the electrolyte is 1mol / l LiPF 6 EC / DMC (1:1) solution, the diaphragm is a composite diaphragm of polypropylene and polyethylene. The ratio of active material: CMC: SBR=96:2:2 is used to prepare pole pieces. Th...

Embodiment 2-5

[0029] The preparation method of negative electrode material is identical with embodiment 1, difference is, prepare 4 samples, change the mass ratio of graphite and tin, be respectively 45:5, 45:10, 45:25 and 45:40, simultaneously the sodium carbonate The molar ratio control of the amount and tin is the same as in Example 1, and the consumption of anhydrous sodium carbonate is respectively 3g, 6g, 15g and 24g, and the prepared samples are respectively designated as sample 2, sample 3, sample 4 and sample 5.

[0030] The above-prepared tin-carbon composite material is the positive electrode, the lithium sheet is the negative electrode, and the electrolyte is 1mol / l LiPF 6 EC / DMC (1:1) solution, the diaphragm is a composite diaphragm of polypropylene and polyethylene. The ratio of active material: CMC: SBR=96:2:2 is used to prepare pole pieces. The test charge and discharge rate is 0.2 C, the charge and discharge voltage is 0.005-2.000 V, and the first discharge specific capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com