Preparation method of pH response type carboxymethyl chitosan/sodium alginate hydrogel ball

A technology of carboxymethyl chitosan and sodium alginate, which is applied in the directions of non-active ingredient medical preparations, pharmaceutical formulations, aerosol delivery, etc., can solve the problems of calcium ion health effects, health effects, chemical residues, etc., Achieve the effect of easy to achieve large-scale production, convenient cleaning and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

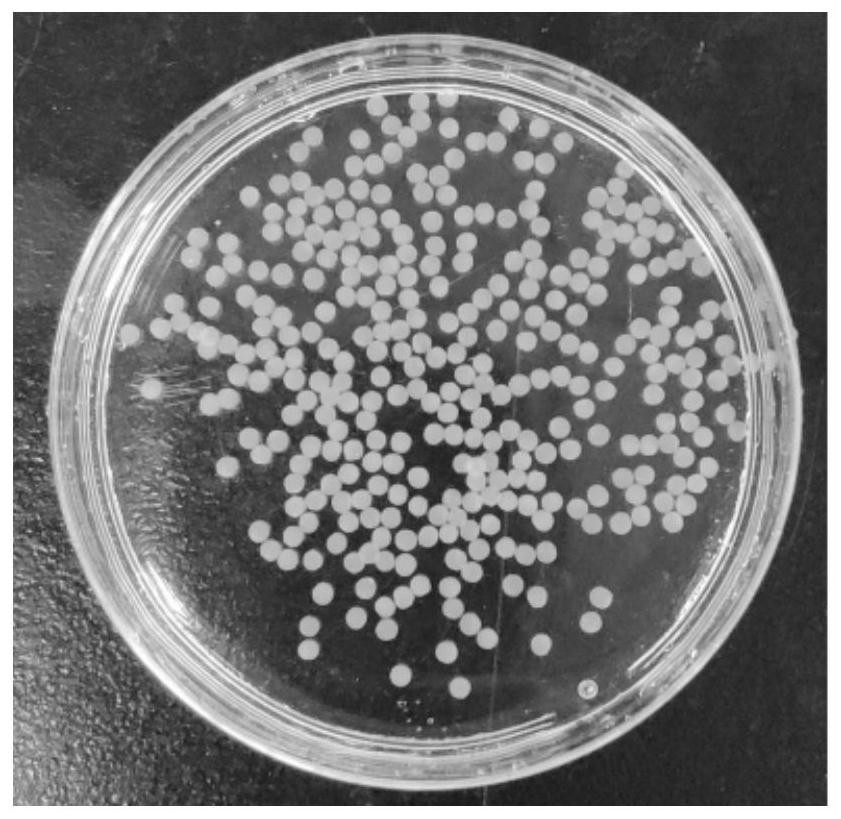

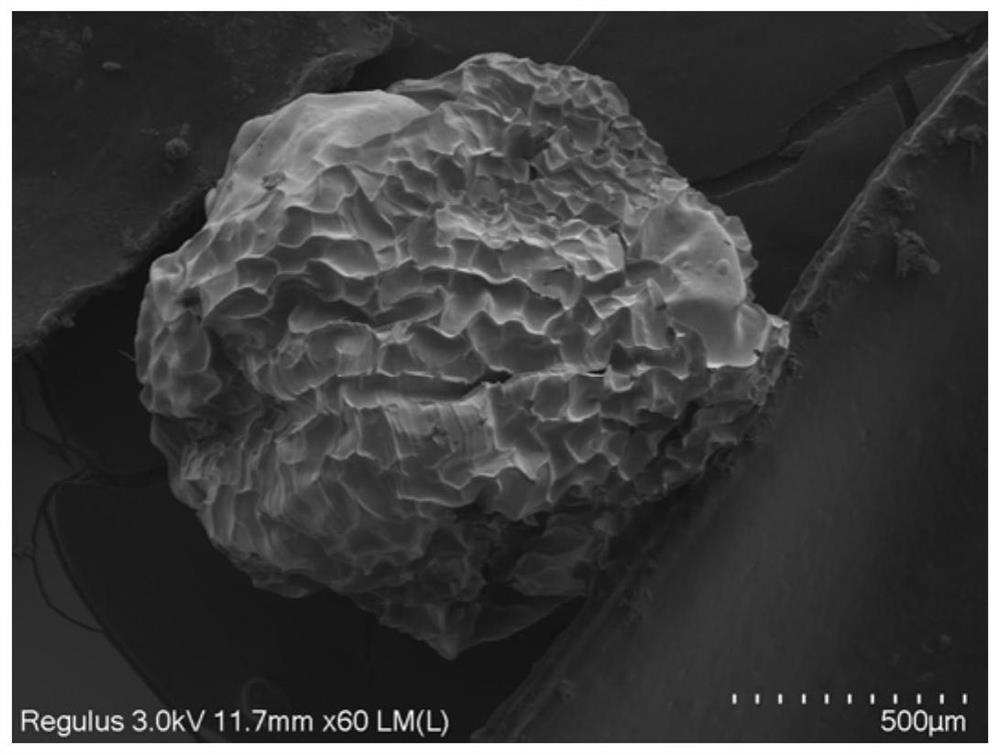

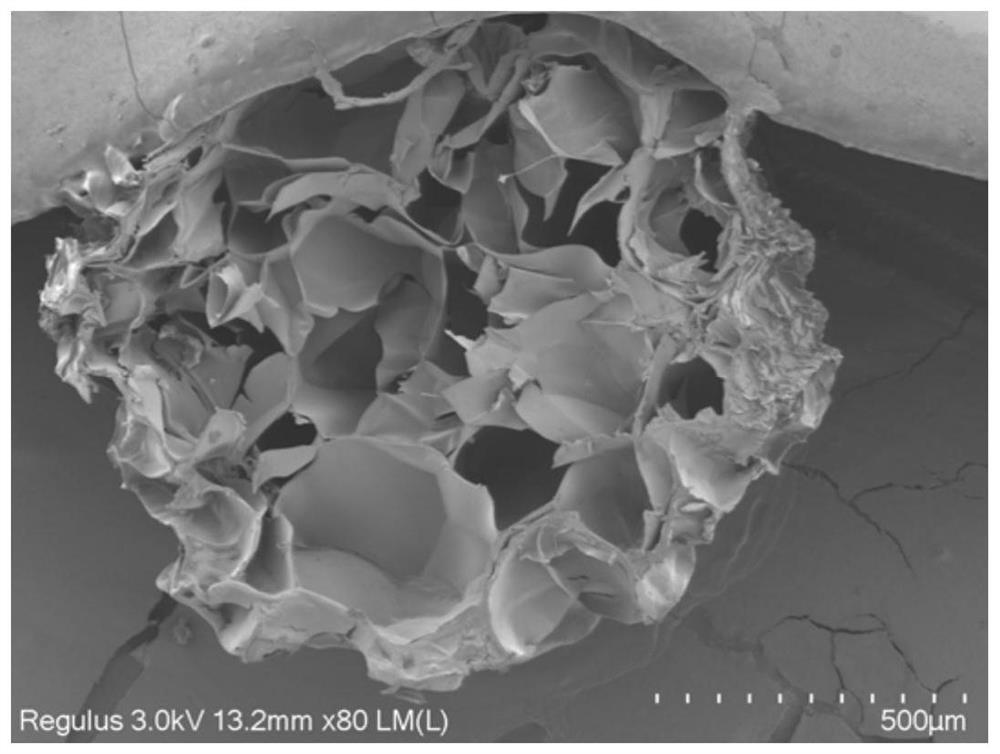

[0044] A preparation method of pH-responsive carboxymethyl chitosan / sodium alginate hydrogel balls, the specific steps are:

[0045] (1) Dissolve 1.0 g of carboxymethyl chitosan in 100 mL of water, stir rapidly to form a homogeneous carboxymethyl chitosan solution, filter, remove insoluble matter, and ultrasonically degas for 30 minutes;

[0046] (2) Dissolve 0.6g of sodium alginate in 100mL of water, stir rapidly to form a uniform sodium alginate solution, filter, remove insoluble substances, and ultrasonically degas for 30 minutes;

[0047] (3) Mix carboxymethyl chitosan solution and sodium alginate solution at a volume ratio of 1:1, stir rapidly to form a uniform carboxymethyl chitosan / sodium alginate mixed solution, and ultrasonically degas for 30 minutes;

[0048] (4) At room temperature, use a 1mL disposable syringe to add the homogeneous mixed solution obtained in step (3) dropwise into a citric acid solution with a concentration of 0.05M for cross-linking, and take out...

Embodiment 2

[0050] A preparation method of pH-responsive carboxymethyl chitosan / sodium alginate hydrogel balls, the specific steps are:

[0051] (1) Dissolve 4.0g carboxymethyl chitosan in 100mL water, stir rapidly to form a uniform carboxymethyl chitosan solution, filter, remove insoluble matter, and ultrasonically degas for 30min;

[0052] (2) Dissolve 1.5g of sodium alginate in 100mL of water, stir rapidly to form a uniform sodium alginate solution, filter, remove insoluble substances, and ultrasonically degas for 30 minutes;

[0053] (3) Mix the carboxymethyl chitosan solution and the sodium alginate solution at a volume ratio of 2:1, stir rapidly to form a uniform carboxymethyl chitosan / sodium alginate mixed solution, and ultrasonically degas for 30 minutes;

[0054] (4) At room temperature, use a 1mL disposable syringe to drop the homogeneous mixed solution obtained in step (3) into a hydrochloric acid solution with a concentration of 0.02M for cross-linking, and take out the cured ...

Embodiment 3

[0056] A preparation method of pH-responsive carboxymethyl chitosan / sodium alginate hydrogel balls, the specific steps are:

[0057] (1) Dissolve 2.5g carboxymethyl chitosan in 100mL water, stir rapidly to form a uniform carboxymethyl chitosan solution, filter, remove insoluble matter, and ultrasonically degas for 30min;

[0058] (2) Dissolve 1.0 g of sodium alginate in 100 mL of water, stir rapidly to form a uniform sodium alginate solution, filter, remove insoluble substances, and degas with ultrasound for 30 minutes;

[0059] (3) Mix carboxymethyl chitosan solution and sodium alginate solution at a volume ratio of 1:2, stir rapidly to form a uniform carboxymethyl chitosan / sodium alginate mixed solution, and ultrasonically degas for 30 minutes;

[0060] (4) At room temperature, use a 1mL disposable syringe to add the homogeneous mixed solution obtained in step (3) dropwise into an aqueous solution of acetic acid with a concentration of 0.07M for cross-linking, and take out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com