Preparation method of niobium diselenide or niobium disulphide/carbon wear-resistant nano composite material

A nanocomposite material, niobium disulfide technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of strict protection requirements for synthetic atmosphere, expensive niobium source, limited application, etc. Achieve the effect of reducing the difficulty of preparation, broadening the application prospect and reducing the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] With absolute ethanol as the dispersion medium, niobium powder, selenium powder and graphite powder were weighed at a mass ratio of Nb:Se:graphite=2:5:1, and mixed in a beaker by magnetic stirring for 2 hours.

[0018] Stand still, remove the supernatant, dry in a blast drying oven at 75°C for 8 hours, remove absolute ethanol, put the dried mixture into a stainless steel reactor and seal it.

[0019] In the tube furnace, the temperature was raised at a rate of 10°C / min, and after the temperature reached 750°C, it was kept for 2 hours, taken out, and naturally cooled to room temperature to obtain NbSe 2 / graphite composites.

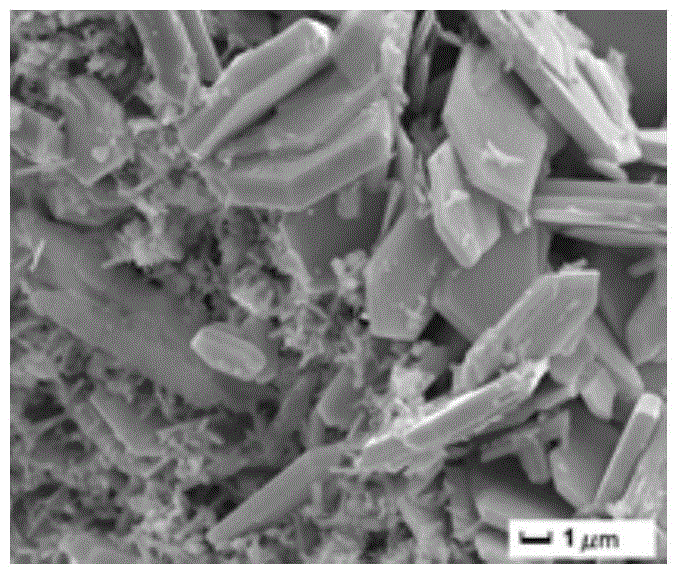

[0020] NbSe 2 / Graphite composites were observed with a scanning electron microscope as figure 1 As shown, NbSe 2 The particle size of the / graphite composite material is 20-300nm, and it has many short rod-like shapes.

[0021] The prepared NbSe 2 / Graphite composite material is added to the base oil paraffin at a certain concentration (0.5-...

Embodiment 2

[0026] Using absolute ethanol as the dispersion medium, weigh niobium powder, sulfur powder and graphite powder at a mass ratio of Nb:S:graphite=2:5:1, and mix them in a beaker for 2 hours by magnetic stirring.

[0027] Stand still, remove the supernatant, dry in a blast drying oven at 75°C for 8 hours, remove absolute ethanol, put the dried mixture into a stainless steel reactor and seal it.

[0028] In the tube furnace, the temperature was raised at a rate of 10°C / min, and after the temperature reached 750°C, it was kept for 2 hours, taken out, and naturally cooled to room temperature to obtain NbS 2 / graphite composites.

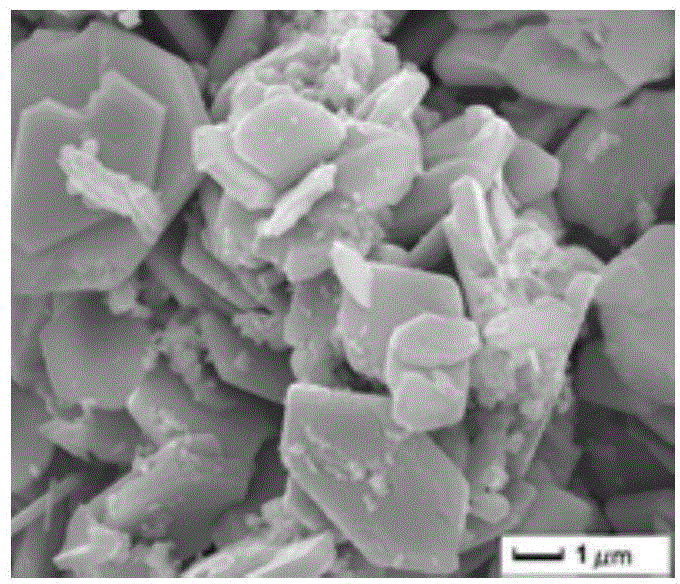

[0029] Nb 2 / Graphite composites were observed with a scanning electron microscope as figure 2 As shown, NbS 2 The particle size of the / graphite composite material is 20-300nm, and it has many short rod-like shapes.

[0030] The prepared NbS 2 / Graphite composite material is added to the base oil paraffin at a certain concentration (0.3-5wt%), and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com