Preparation method of sesamin phenol

A technology of sesaminol and sesaminol, which is applied in the preparation field of sesaminol, can solve the problems of complex sesaminol method steps, can not meet the high requirements of industrialized production and equipment technical level, and achieves green technology, low cost and raw materials. easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

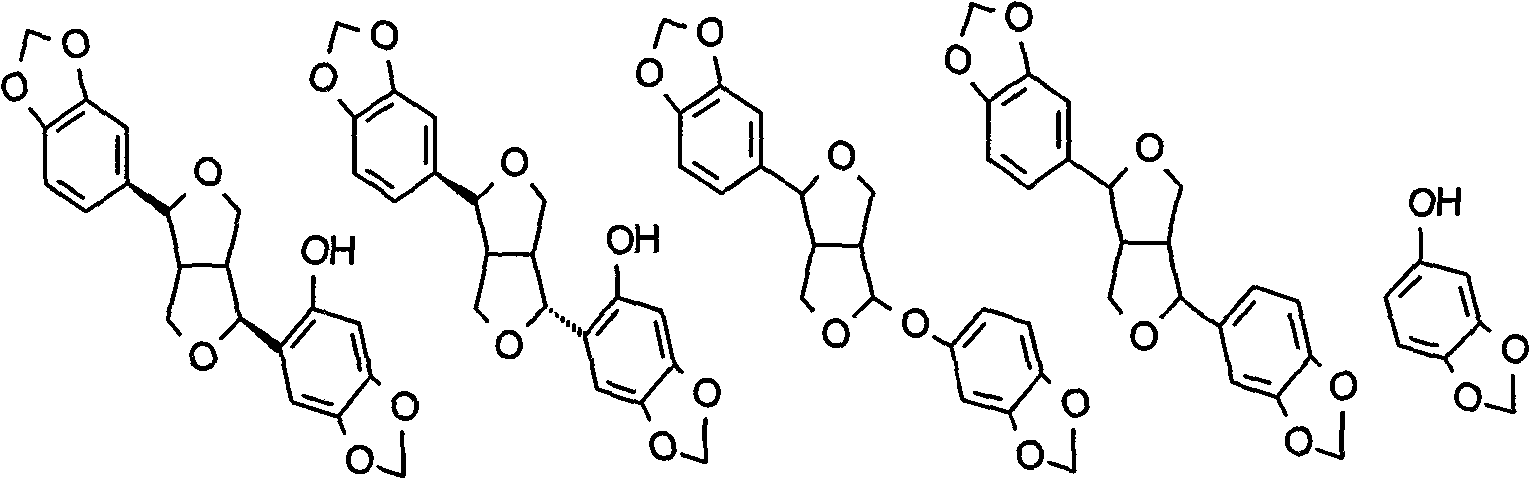

Image

Examples

Embodiment 1

[0025] Get sesamolin crude product (containing sesamolin 62.9% and sesamolin 36.2%) 0.5g (containing sesamolin 0.85mmol), 20mL toluene joins in the 50mL three-necked flask (the initial concentration of sesamolin is 42.5mmol L -1 ), stirred and preheated to 100°C, then added 15g of 001x7 cation exchange resin (polystyrene matrix) treated into H type and dried (17.6g·mmol relative to the initial sesamolin -1 ), kept stirring and kept the same temperature for 2h, and HPLC measured the reaction solution when reacting for 2h, and the yield of converting sesaminol was 81.5%. Suction filtration after cooling, the catalyst was washed twice with acetone, the filtrates were combined, and the solvent was evaporated under reduced pressure to obtain a yellow-brown paste solid, which was purified by silica gel column chromatography, and first eluted with n-hexane and ethyl acetate at a ratio of 8:1 , TLC monitoring reaction (developing agent is n-hexane: ethyl acetate=4: 1), when the eluent...

Embodiment 2

[0027] Get sesamolin pure product (purity is 98%) 40mg (0.108mmol), 10mL xylene joins in the 25mL three-necked flask (sesamolin concentration is 10.8mmol L -1 ), stirred and preheated to 90°C, then added 1.5g of D001 cation exchange resin (macroporous polystyrene matrix) treated into H type and dried (13.89g·mmol relative to the initial sesamolin -1 ), kept stirring and kept the same temperature for 4h, HPLC measured the reaction solution after 4h, and converted to 73.8% of the yield of sesaminol. After cooling, it was filtered with suction, washed twice with ethyl acetate, and the filtrates were combined, and the solvent was evaporated under reduced pressure to obtain a yellow-brown paste solid, which was purified by silica gel column chromatography, eluted with n-hexane and ethyl acetate at a ratio of 4:1, monitored by TLC, and collected For the sesamol component, the solvent was evaporated under reduced pressure to obtain 25.6 mg of yellow-brown sesamol solid, the total ses...

Embodiment 3

[0029] Get sesamolin pure product (purity is 98%) 66mg (0.18mmol), 10mL benzene joins in the 25mL three-necked flask (sesamolin concentration is 18mmol L -1 ), stirred and pre-heated to 70 ° C, then added 0.72 g of 001x7 cation exchange resin (polystyrene matrix) treated into H type and dried (4 g·mmol relative to the initial sesamolin -1 ), kept stirring and kept the same temperature for 5h, and HPLC measured the reaction solution after 5h, and the yield of converting sesaminol was 68.9%. Afterwards, according to the method of Example 2, 38.7 mg of yellow-brown sesamol solid was obtained, and the total sesamol content determined by HPLC was 98.2%, and the yield was 58.6%, wherein the sesamol content was its isomer 2-episesamin 1.42 times that of phenol. Sesamolin pure product, benzene, and catalyst are dehydrated and dried before the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com