Preparing method of edible chitosan elastic sponge with aromatic odor

A technology of aromatic smell and elastic sponge, which is applied in the field of elastic sponge, can solve the problems of application limitation, strong corrosion, harshness, etc., and achieve the effects of fast self-recovery ability, good fatigue resistance, and strong elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

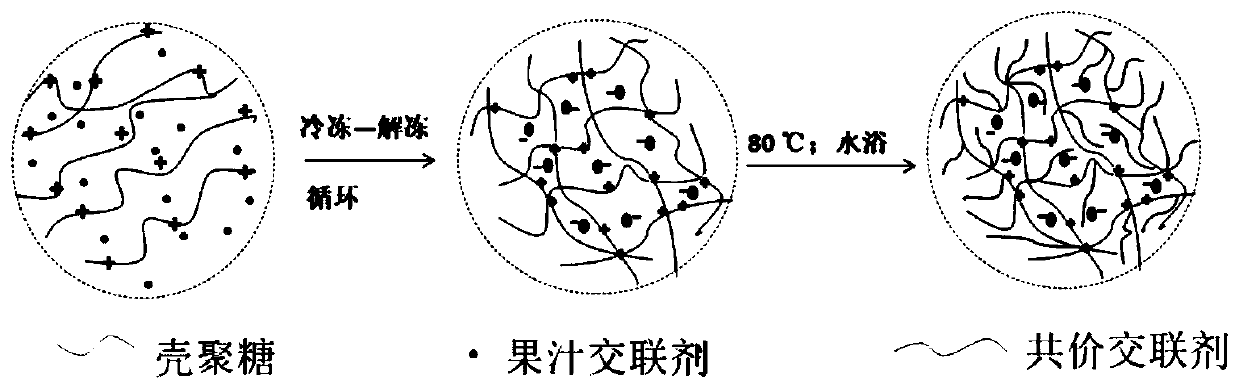

[0037] Embodiment 1 has aromatic smell and the preparation of edible chitosan elastic sponge

[0038] The specific process is as follows:

[0039] S1. Take by weighing 1.2g chitosan powder, wherein the deacetylation degree of chitosan is 98%, molecular weight is 50KDa, is dispersed in 60mL deionized water at room temperature to form turbid liquid, with 1% (w / v) edible white vinegar Add above-mentioned turbid solution, obtain the chitosan-acid solution of 2.0% (w / v);

[0040] S2. Squeeze the lemon juice and dilute it by 1 time;

[0041] S3. Add the lemon juice obtained above to the chitosan-acid solution drop by drop, and continue stirring to fully cross-link chitosan and lemon juice to obtain a suspension; pour the suspension into twelve In the orifice plate, after standing still for defoaming, put it in the refrigerator to freeze at -20°C, thaw at room temperature, and cycle freeze-thaw three times; finally place it in a vacuum freeze dryer for freeze-drying for 18 hours to...

Embodiment 2

[0046] A kind of chitosan elastic sponge that has aromatic smell and edible, concrete preparation process is as follows:

[0047] S1. Take by weighing 0.6g chitosan powder, wherein the deacetylation degree of chitosan is 90%, molecular weight is 20KDa, is dispersed in 60mL deionized water at room temperature and forms turbid liquid, mixes 1% (w / v) citric acid Add above-mentioned turbid solution, obtain the chitosan-acid solution of 1.0% (w / v);

[0048] S2. Juicing the lime to obtain lime juice;

[0049] S3. Add lime juice dropwise to the above-mentioned chitosan-acid solution, continue to stir, so that chitosan and fruit juice are fully cross-linked to obtain a suspension; the suspension is poured into a twelve-hole plate, After standing still for defoaming, put it in the refrigerator to freeze at -20°C, and freeze-thaw cycle three times; finally, place it in a vacuum freeze dryer to freeze-dry for 24 hours;

[0050] S4. Then put the freeze-dried sample into a citral food-gr...

Embodiment 3

[0052] A kind of chitosan elastic sponge that has aromatic smell and edible, concrete preparation process is as follows:

[0053] S1. take by weighing 1.8g chitosan powder, wherein the degree of deacetylation of chitosan is 98%, molecular weight is 70KDa, is dispersed in 60mL deionized water at room temperature to form cloudy liquid, adds 1% (w / v) lactic acid Above-mentioned turbid solution obtains the chitosan-acid solution of 3.0% (w / v);

[0054] S2. Juicing the grapes to obtain grape juice;

[0055] S3. Add grape juice dropwise to the above-mentioned chitosan-acid solution, continue to stir, so that chitosan and fruit juice are fully cross-linked to obtain a suspension; this suspension is poured into a twelve-hole plate, After standing still for defoaming, put it in the refrigerator to freeze at -20°C, and freeze-thaw cycle three times; finally, place it in a vacuum freeze dryer to freeze-dry for 24 hours;

[0056] S4. Then put the freeze-dried sample into a food-grade et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com