Cu-VSB 5 catalyst for hydroxylation of phenol, and preparation method

A technology of phenol hydroxylation and VSB-5, which is applied in the preparation of organic compounds, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the difficult separation of catalysts to achieve reuse, hinder the application of industrialization, and the output is not very high, etc. problem, to achieve the effect of low raw material cost, easy recycling, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

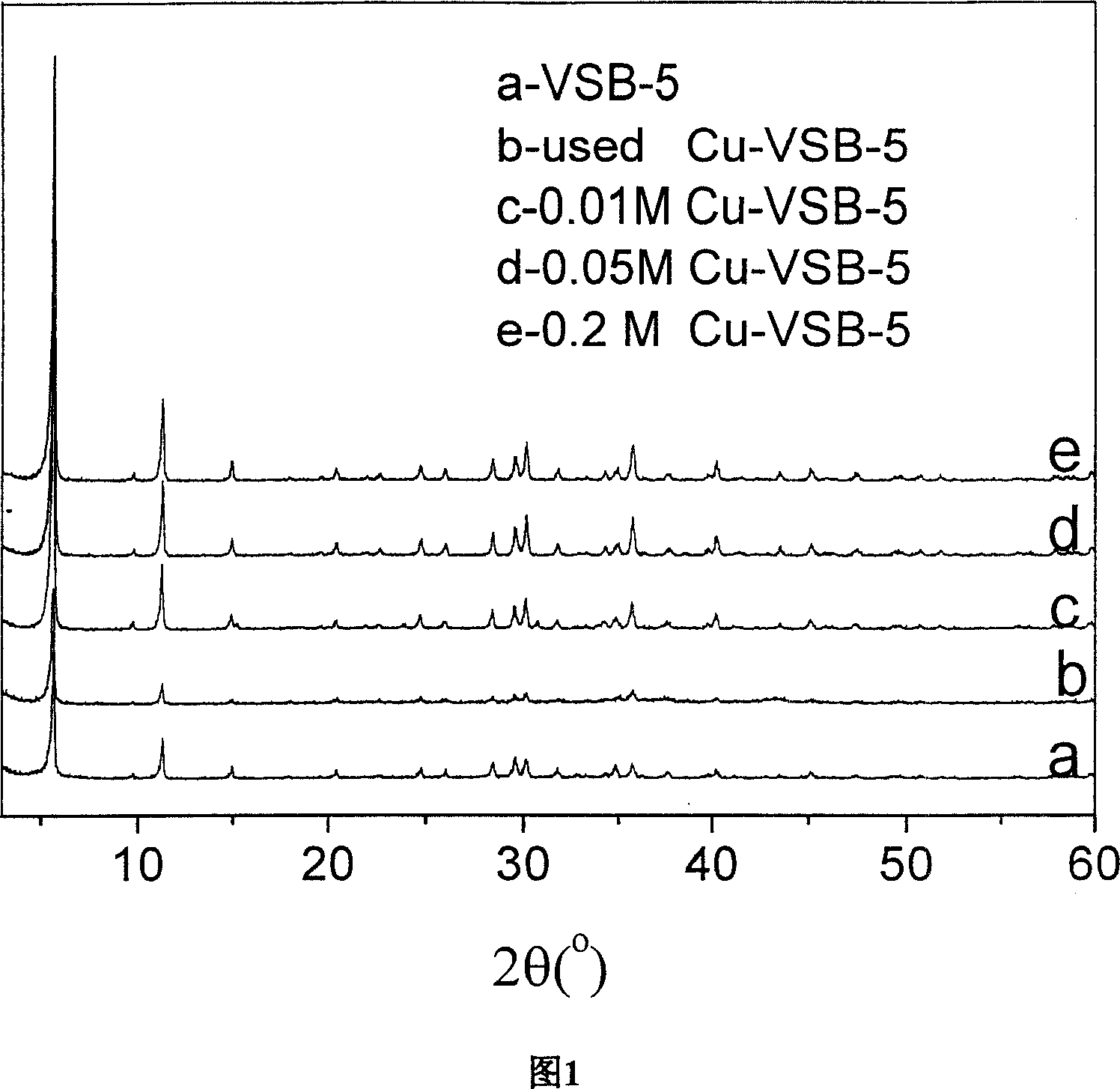

[0028] Prepare 0.2 mol / L copper nitrate solution, then add VSB-5 powder, stir at room temperature for 6 hours, then wash repeatedly with deionized water and dry. Activate the dried powder by firing at 350°C for 3 hours to obtain 0.2Cu-VSB-5 powder

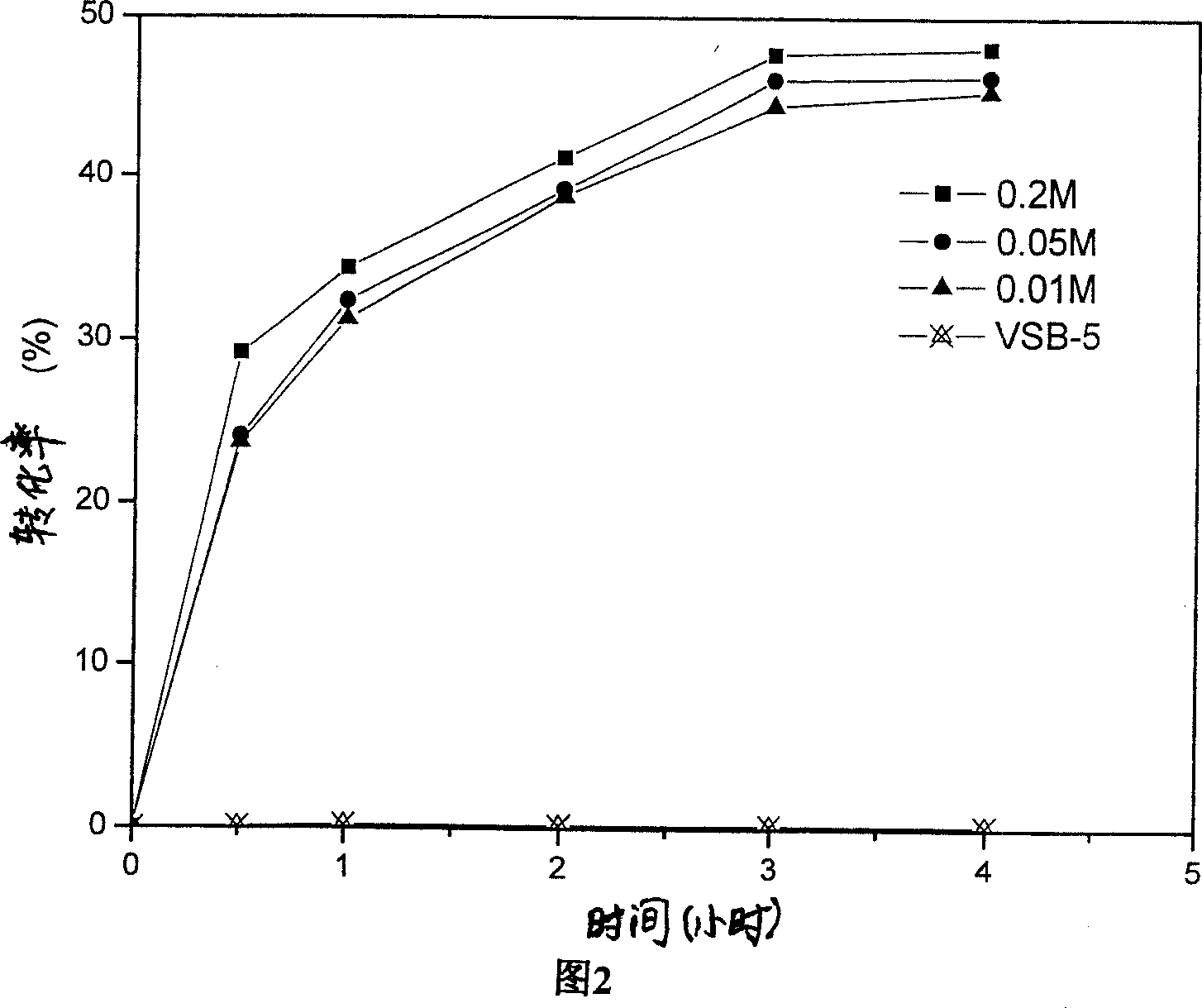

[0029] Weigh 0.094g of phenol and add it to a round bottom flask filled with 30ml of water. The mixture is heated to 60°C under stirring, and then 0.094g0.2Cu-VSB-5 is added. Samples were taken every half hour for quantitative analysis. When the reaction time was 3 hours, the conversion rate of phenol in the solution was 47.7%.

Embodiment 2

[0031] The copper nitrate solution of preparation 0.05 mol / liter, all the other steps are with embodiment 1.

[0032] Weigh 0.094g of phenol and add it to a 30ml round bottom flask. The mixture is heated to 60°C under stirring, and then 0.094g0.05Cu-VSB-5 is added. Samples were taken every half hour for quantitative analysis. When the reaction time was 3 hours, the conversion rate of phenol in the solution was 46.1%.

Embodiment 3

[0034] The copper nitrate solution of preparation 0.01 mol / liter, all the other steps are with embodiment 1.

[0035] Weigh 0.094g of phenol and add it to a round-bottomed flask filled with 30ml of water. The mixture is heated to 60°C with stirring, and then 0.094g0.01Cu-VSB-5 is added. Samples were taken every half hour for quantitative analysis. When the reaction time was 3 hours, the conversion rate of phenol in the solution was 44.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com