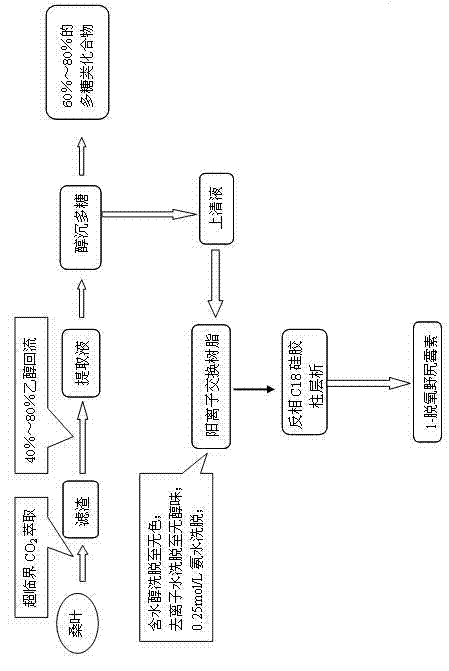

Method for continuously extracting and separating polysaccharides and 1-deoxynojirimycin from mulberry leaves

A technology of deoxynojirimycin and mulberry leaves, applied in the production of bulk chemicals, organic chemistry, etc., to achieve the effects of improving extraction rate, enhancing dissolution, and leaving no extractant residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 400g of crushed mulberry leaf raw materials into the barrel and place the extraction cylinder, turn on the supercritical CO 2 Extraction device, extraction temperature 40°C, extraction pressure 30Mpa extraction for 80 minutes, CO 2 The flow rate is 30L / h. After the extraction, take out the barrel to obtain mulberry leaf residue, add 4L of 65% ethanol after drying, the ratio of solid to liquid is 1:10, stir at 80°C for 2h, and filter to obtain the filtrate. Add 4L of 65% ethanol to the filter residue to repeat extraction once and filter, combine the filtrate obtained twice, and concentrate to 200mL. Add 1.8L of 95% ethanol to the concentrated solution, let it stand for 4 hours, centrifuge, collect the precipitate, and dry at low temperature to obtain a light yellow powder, which is mulberry leaf polysaccharide. The content of mulberry leaf polysaccharide was determined by the phenol-sulfuric acid method to be 71%. The supernatant was concentrated to about 100 mL, a...

Embodiment 2

[0025] Add 400g of crushed mulberry leaf raw materials into the barrel and place the extraction cylinder, turn on the supercritical CO 2 Extraction device, extraction temperature 50°C, extraction pressure 40Mpa for 100 minutes, CO 2 The flow rate is 50L / h. After the extraction, the barrel was taken out to obtain mulberry leaf residue, after drying, 6 L of 60% ethanol was added, stirred at 80° C. for 2 h, and filtered to obtain the filtrate. Add 6L of 60% ethanol to the filter residue to repeat extraction once and filter, combine the filtrate obtained twice, and concentrate to 200mL. Add 1.5L of 95% ethanol to the concentrated solution, let it stand for 4 hours, centrifuge, collect the precipitate, and dry at low temperature to obtain a light yellow powder, which is mulberry leaf polysaccharide. The content of mulberry leaf polysaccharide was determined by the phenol-sulfuric acid method to be 69%. The supernatant was concentrated to about 100 mL, and passed through a pretrea...

Embodiment 3

[0027] Add 400g of crushed mulberry leaf raw materials into the barrel and place the extraction cylinder, turn on the supercritical CO 2 Extraction device, extraction temperature 35°C, extraction pressure 40Mpa extraction 120 minutes, CO 2The flow rate is 40L / h. After the extraction, the barrel was taken out to obtain mulberry leaf residue, after drying, 5 L of 75% ethanol was added, stirred at 80° C. for 2 h, and filtered to obtain the filtrate. Add 5 L of 75% ethanol to the filter residue to repeat extraction once and filter, combine the filtrate obtained twice, and concentrate to 200 mL. Add 1.6L of 95% ethanol to the concentrated solution, let it stand for 4 hours, centrifuge, collect the precipitate, and dry at low temperature to obtain a light yellow powder, which is mulberry leaf polysaccharide. The content of mulberry leaf polysaccharide was determined by the phenol-sulfuric acid method to be 74%. The supernatant was concentrated to about 100 mL, and passed through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com