Magnetic force internal formation method of power-type lead accumulator

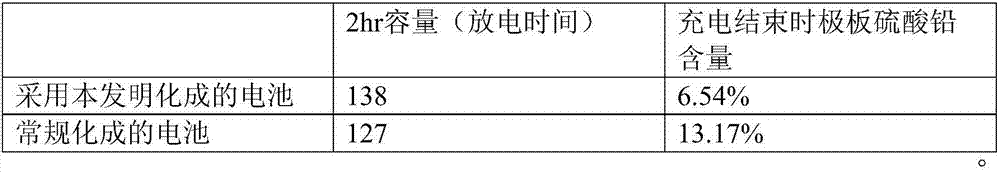

A lead-acid battery, internal formation technology, applied in the direction of lead-acid batteries, lead-acid battery construction, secondary batteries, etc., can solve the problems of low plate formation efficiency, early capacity decay, acid layering, etc., to solve the initial The effect of low capacity, increased fluidity, and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] A method for internalizing the magnetic force of a power-type lead storage battery, comprising the following steps:

[0038] (1) Acid filling: Pour sulfuric acid solution into the lead storage battery through an acid pot, and then let it stand for 1 to 2 hours. The amount of sulfuric acid solution added to a single cell of the lead storage battery is 11 to 13ml / Ah, and the density of the sulfuric acid solution is 1.28-1.32g / cm 3 .

[0039] (2) The battery treated in step (1) is first charged with a current of 0.05-0.1C for 2 to 3 hours, and then charged with a current of 0.1-0.2C for 3 to 5 hours. During this process, an electromagnetic field is applied to the formed battery A: Frequency 12~18kHz, the power is 150~180 milliwatts, and the electromagnetic field is adjusted to the opposite polarity.

[0040] (3) Continue to charge at a current of 0.4-0.5C until the battery voltage is 15.6-15.8V / pc, let it stand for 0.2 hours, then continue to charge at a current of 0.2-0....

Embodiment 16-D

[0046] Embodiment 1 takes 6-DZM-12Ah battery as an example

[0047] A method for magnetically internalizing a power type lead-acid storage battery, comprising the following steps:

[0048] (1) pour acid, place the magnetic field source and pour sulfuric acid solution into the lead storage battery through the acid pot, add sulfuric acid quantitatively according to the ratio of sulfuric acid: anode lead oxide liquid-solid ratio is 1ml:1.2g (density is 1.28g / cm 3 ), the amount of sulfuric acid solution in a single cell is 142ml, and stand for 1 hour. During this process, the magnetic field source and modulation device are placed next to the formation battery, so that the formation battery is within the coverage of its magnetic field.

[0049] (2) Charge with a current of 1.2A (1C=12A) for 3 hours, and then charge with a current of 1.8A for 5 hours. During this process, the magnetic field source is modulated to a specific frequency of 12kHz and a power value of 150 milliwatts by a...

Embodiment 26-D

[0056] Embodiment 2 takes 6-DZM-20Ah battery as an example

[0057] A method for magnetically internalizing a power type lead-acid storage battery, comprising the following steps:

[0058] (1) Acid filling: Place the magnetic field source and pour sulfuric acid solution into the lead storage battery through the acid pot, add sulfuric acid quantitatively according to the ratio of sulfuric acid: positive lead oxide liquid-solid ratio is 1ml: 1.3g (density is 1.30g / cm 3 ), the amount of sulfuric acid solution per cell was 235ml, and stood for 2 hours. During this process, the magnetic field source and modulation device were placed next to the formation battery, so that the formation battery was within the coverage of its magnetic field.

[0059] (2) Charge with a current of 2A for 4 hours, and then charge with a current of 3A for 4 hours. During this process, the magnetic field source is modulated to a specific frequency of 15kHz and a power value of 170 milliwatts through the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com