A plate heat exchanger

A technology of plate heat exchangers and heat exchangers, applied in heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

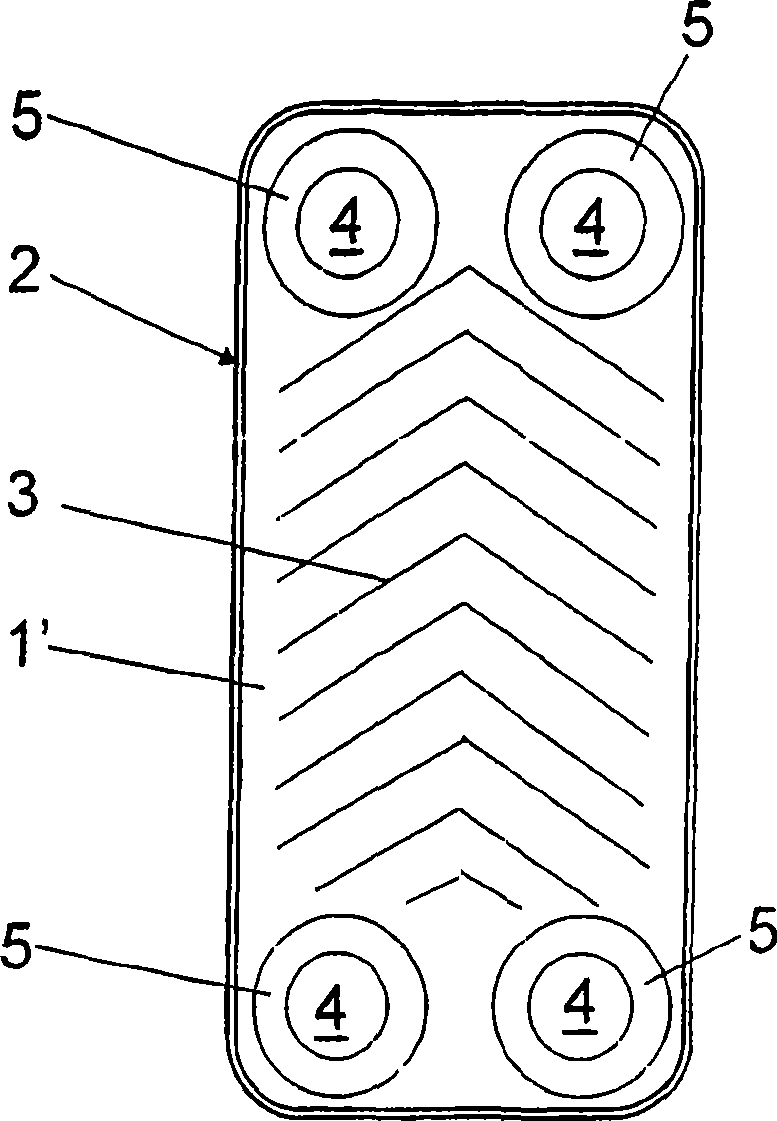

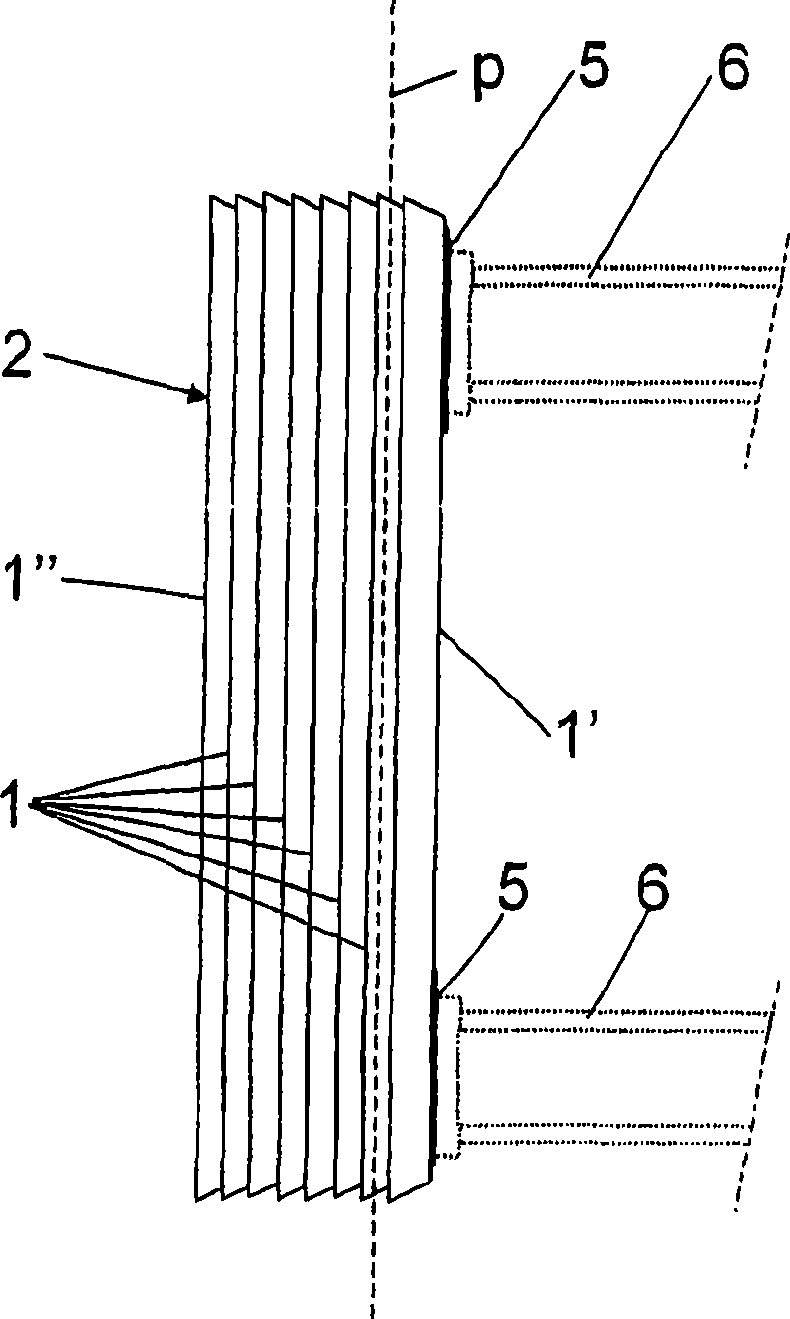

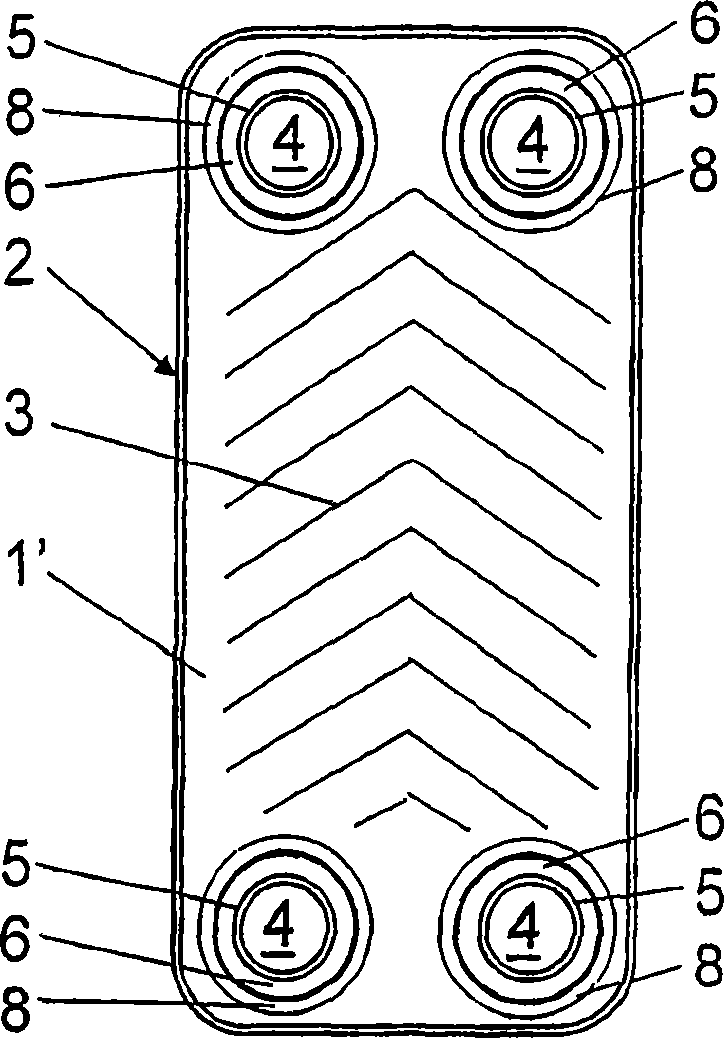

[0024] Figure 1-6 Different embodiments of plate heat exchangers are shown. In all embodiments the plate heat exchanger comprises a plurality of heat exchanger plates 1 which are arranged next to each other so as to form a plate pack 2 . Each heat exchanger plate 1 comprises, in a manner known in the art, corrugations 3 for enhancing heat transfer, and four port holes for forming a corresponding number of port channels 4 extending through the plate pack 2 . It should be noted that the board assembly 2 may comprise different Figure 1-6 Other numbers of port channels than the four port channels disclosed in the illustrated embodiment.

[0025] The plate pack 2 comprises a first outer heat exchanger plate 1' and a second outer heat exchanger plate 1". Between these two heat exchanger plates the remaining heat exchanger plates 1 are arranged. In the shown embodiment In the example, the first outer heat exchanger plate 1' is also provided with port holes aligned with the port ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com