Low temperature denitration catalytic addictive and preparation method thereof

A low-temperature denitrification and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of high denitrification rate, alkali metal poisoning, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

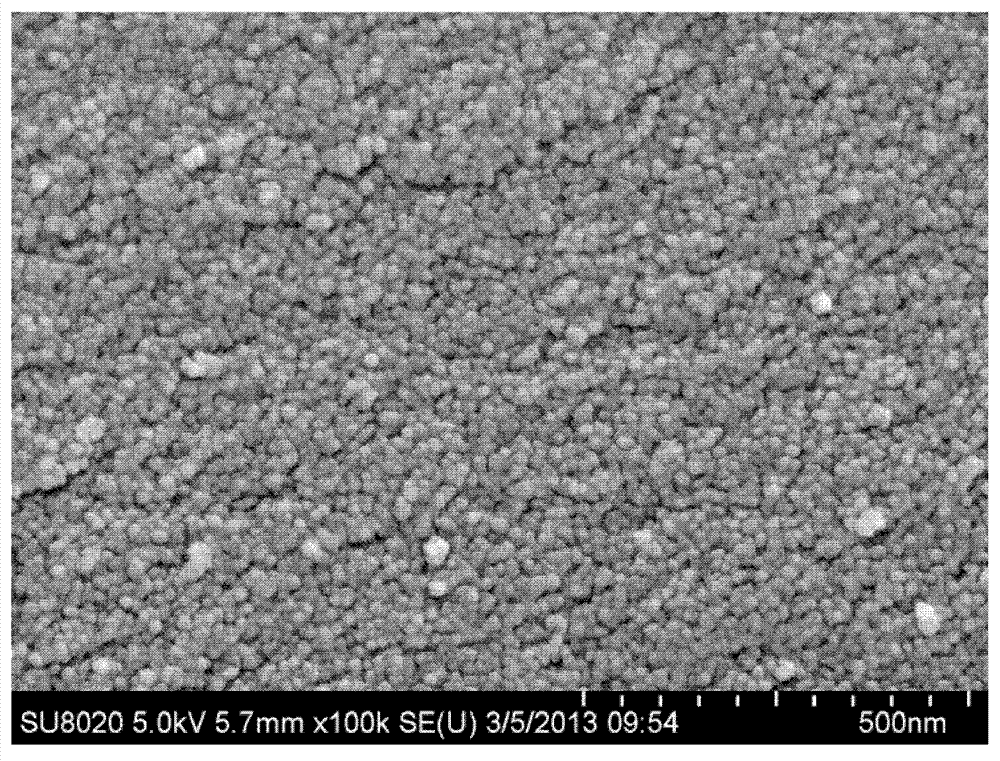

[0026] A TiO 2 -SiO 2 As a composite carrier, CeO 2 The manganese-based denitration catalyst as an auxiliary agent is recorded as Mn-Ce / Ti-Si where Mn:(Ti+Si)=0.8:1, Ce:(Ti+Si)=0.07:1, and the preparation includes the following steps:

[0027] In the first step, mix 34.6g of tetraethyl orthosilicate with 150ml of absolute ethanol, stir for 2 minutes, then add 3ml of acetic acid and 15ml of deionized water, stir for 5 minutes with magnetic force, and record it as solution A.

[0028] In the second step, mix 42g of tetrabutyl titanate with 150ml of absolute ethanol, stir it magnetically for 5 minutes, and record it as solution B

[0029] In the third step, mix 100ml of ethanol, 5ml of acetic acid and 25ml of deionized water evenly, and record it as solution C.

[0030] In the fourth step, add solution A in the first step to solution B dropwise to obtain a mixed solution, then add solution C dropwise to the mixed solution, put it in a water bath at 40°C and stir vigorously until...

Embodiment 3

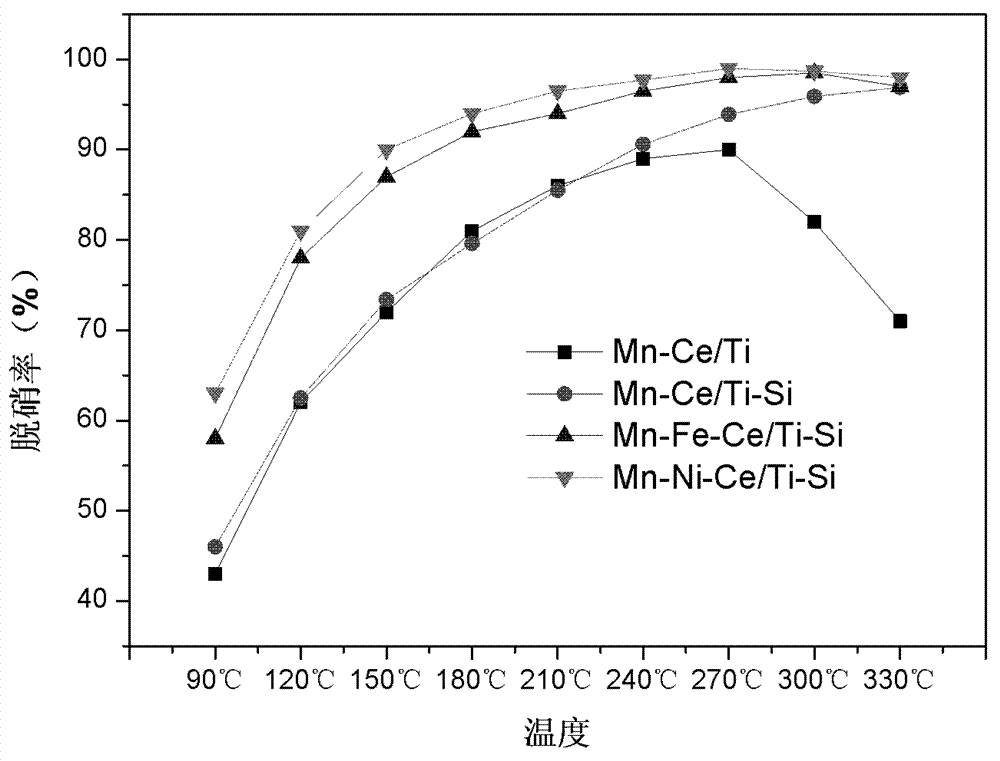

[0034] A TiO 2 -SiO 2 As a composite carrier, CeO 2 The low-temperature denitrification catalyst with NiO as the auxiliary agent is recorded as Mn-Ni-Ce / Ti-Si, where Mn:(Ti+Si)=0.8:1, and the mass ratio of Ce, Ni and (Ti+Si) is 0.07 : 1, the preparation comprises the following steps:

[0035] In the first step, TiO is also prepared by the method in Example 2 2 -SiO 2 Composite carrier.

[0036] In the second step, 56.9g of manganese acetate, 7.6g of cerium nitrate, and 5.1g of nickel nitrate were dissolved in deionized water, magnetically stirred until completely dissolved, and 5g of TiO 2 -SiO 2 Immerse the composite carrier into the solution, stir magnetically for 20 minutes, let it stand for 10 hours, put it in a drying oven at 110°C to dry, and after drying, put it in a muffle furnace for calcination at 450°C for 4 hours, and grind to obtain the finished product Mn-Ni- Ce / Ti-Si catalyst.

Embodiment 4

[0038] A TiO 2 -SiO 2 As a composite carrier, CeO 2 The low-temperature denitrification catalyst with FeOx as the auxiliary agent is recorded as Mn-Fe-Ce / Ti-Si, where Mn: (Ti+Si) = 0.8:1, and the mass ratio of Ce, Fe and (Ti+Si) is 0.07:1, the preparation includes the following steps:

[0039] In the first step, TiO is also prepared by the method in Example 2 2 -SiO 2 Composite carrier.

[0040] In the second step, dissolve 56.9g of manganese acetate, 7.6g of cerium nitrate, and 7.1g of ferric nitrate in deionized water, stir magnetically until the dissolution is complete, and weigh 5g of TiO 2 -SiO 2 Immerse the composite carrier into the solution, stir it magnetically for 20 minutes, let it stand for 10 hours, put it in a drying oven to dry at 110°C, put it into a muffle furnace for calcination at 450°C for 4 hours after drying, and grind to obtain the finished product Mn-Fe- Ce / Ti-Si catalyst.

[0041] The above four catalysts are all in the form of NH 3 For reduci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com