Zn-modified multi-level pore HZSM-5 catalyst and application thereof in liquefied gas aromatization

A catalyst, multi-level pore technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of limited large-scale application, coke deactivation, and acid catalytic performance degradation, and reduce cracking. effect, improve selectivity, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

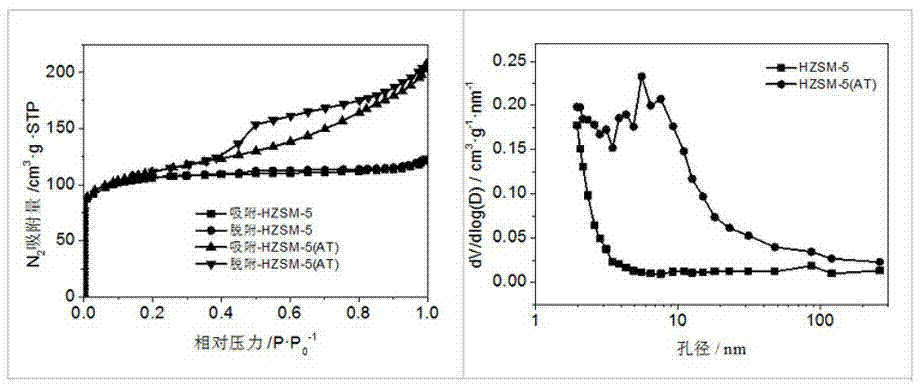

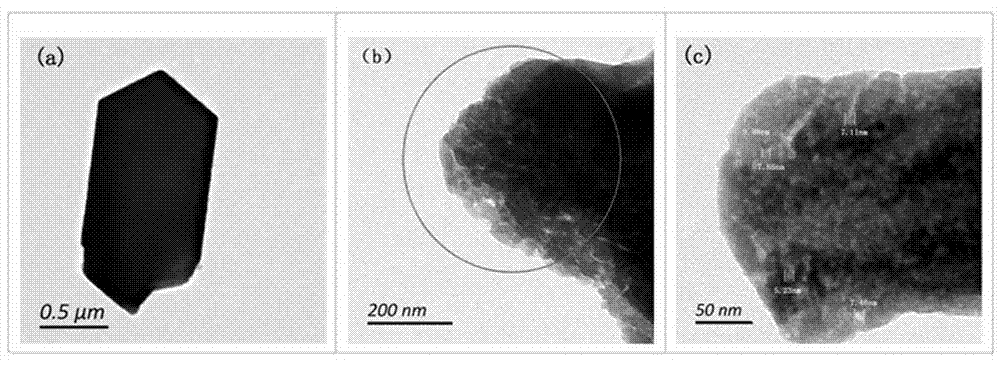

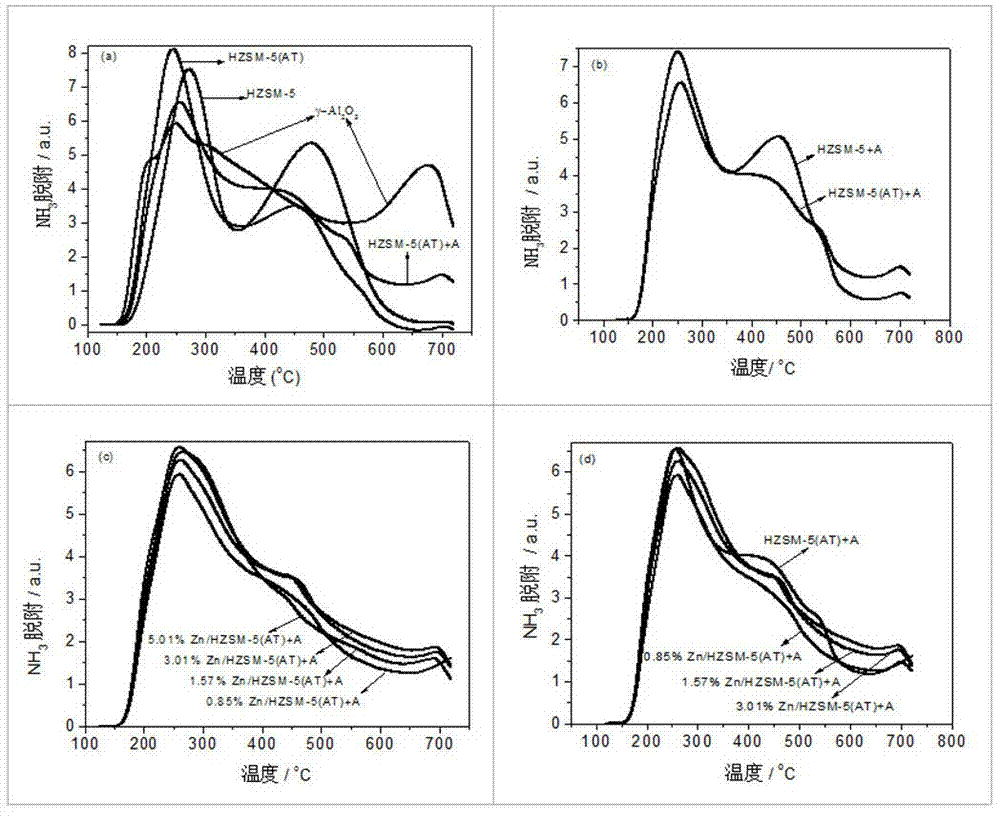

[0030] 10g of HZSM-5 (nSiO 2 / nAl 2 o 3 =38) dissolved in 600ml NaOH (0.1 mol / L) solution, 50 o C and stirred for 30min, the solution was cooled and the pH value was adjusted to 7 with dilute nitric acid, then suction filtered, washed, 100 o C was dried for 3 hours to obtain alkali-modified Na-type ZSM-5, labeled as NaZSM-5(AT);

[0031] NaZSM-5(AT) was treated with 0.5 mol / L NH 4 NO 3 The solution was ion-exchanged three times, filtered, washed, dried and 500 o C was roasted for 3 h to obtain alkali-modified hydrogen ZSM-5, labeled as HZSM-5(AT);

[0032] Mix HZSM-5(AT) and pseudo-boehmite AlO(OH) at a mass ratio of 4:6, stir evenly, add dilute nitric acid solution with a mass concentration of 1% and form a mass and knead repeatedly, 100 o C drying 3h, 500 oC is calcined for 3 h, and the industrial catalyst obtained is marked as HZSM-5(AT)+A;

[0033] Using Zn(NO 3 ) 2 The solution was fully impregnated with HZSM-5(AT)+A in an equal volume under negative pressure, ...

Embodiment 2

[0035] 10g of HZSM-5 (nSiO 2 / nAl 2 o 3 =50) dissolved in 600ml NaOH (0.5 mol / L) solution, 100 o C and stirred for 300min, the solution was cooled and the pH value was adjusted to 7 with dilute nitric acid, then suction filtered, washed, 150 o C dried for 12 hours to obtain alkali-modified Na-type ZSM-5, labeled as NaZSM-5(AT);

[0036] NaZSM-5(AT) was treated with 3 mol / L NH 4 NO 3 The solution was ion-exchanged three times, filtered, washed, dried and 550 o C was roasted for 12 h to obtain alkali-modified hydrogen ZSM-5, labeled as HZSM-5(AT);

[0037] Mix HZSM-5(AT) and pseudo-boehmite AlO(OH) at a mass ratio of 8:2, stir evenly, add dilute nitric acid solution with a mass concentration of 10% and form a mass and knead repeatedly, 150 o C drying 12h, 550 o C is calcined for 12 h, and the industrial catalyst obtained is marked as HZSM-5(AT)+A;

[0038] Using Zn(NO 3 ) 2 The solution was fully impregnated with HZSM-5(AT)+ A in an equal volume under negative pressur...

Embodiment 3

[0040] 10g of HZSM-5 (nSiO 2 / nAl 2 o 3 =38) dissolved in 600ml NaOH (0.2 mol / L) solution, 60 o C and stirred for 120min, the solution was cooled and the pH value was adjusted to 7 with dilute nitric acid, then suction filtered, washed, 110 o C dried for 6h to obtain alkali-modified Na-type ZSM-5, labeled as NaZSM-5(AT);

[0041] NaZSM-5(AT) was treated with 1.0 mol / L NH 4 NO 3 The solution was ion-exchanged three times, filtered, washed, dried and 520 o C is roasted for 3 hours to obtain alkali-modified hydrogen ZSM-5, marked as HZSM-5(AT);

[0042] Mix HZSM-5(AT) and pseudo-boehmite AlO(OH) at a mass ratio of 7:3, stir evenly, add dropwise 3% dilute nitric acid solution and knead repeatedly, 120 o C drying 3h, 550 o C is calcined for 6h, and the industrial catalyst obtained is marked as HZSM-5(AT)+A;

[0043] Using Zn(NO 3 ) 2 The solution was fully impregnated with HZSM-5(AT)+A in an equal volume under negative pressure, and stood at room temperature for 24h, 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com