Method for preparing silicon oxide aerogel pellet at normal pressure at normal pressure

A silicon oxide aerogel, silicon oxide technology, applied in the directions of silicon oxide, silicon dioxide, chemical instruments and methods, etc., can solve the problems of complex oil phase composition, high price, increased cost, etc., and achieves high adsorption rate and adsorption. Good performance and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

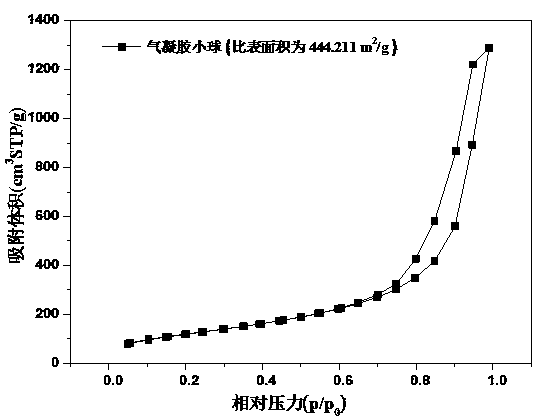

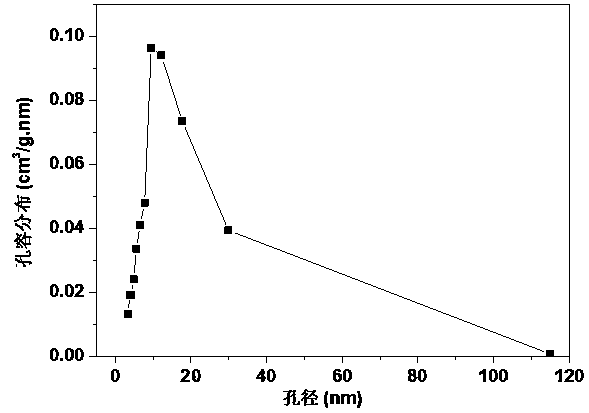

Embodiment 1

[0033] Measure 2.6 mL of glacial acetic acid in a beaker for later use; weigh 16 g of water glass in a beaker, measure 50 mL of cooled deionized water to dilute the water glass for later use; under stirring, drop the water glass into hydrochloric acid, the solution pH About 5.8. The prepared sol was added dropwise into simethicone oil at 75° C. at a height of 15 cm to form silica wet gel beads. The prepared silica wet gel beads were washed with water 4 times, each time for 2 h, at a washing temperature of 50 °C; then, the silica wet gel beads were soaked in absolute ethanol for 4 times, each time for 2 h, and the aging temperature was 50°C; transfer the silica wet gel beads to tetraethyl orthosilicate ethanol solution and soak for 24 h at 50°C; finally soak the silica wet gel beads in n-hexane for 4 times, The immersion temperature was 45°C for 3 hours each time; the silica airgel pellets were prepared by drying the silica wet gel pellets in a desiccator at 30°C.

Embodiment 2

[0035] Measure 2.6 mL of glacial acetic acid in a beaker for later use; weigh 16 g of water glass in a beaker, measure 50 mL of cooled deionized water to dilute the water glass for later use; under stirring, drop the water glass into hydrochloric acid, the solution pH About 5.8. The prepared sol was added dropwise into simethicone oil at a height of 25 cm at 65° C. to form silica wet gel beads. The prepared silica wet gel beads were washed 4 times, 2 h each time, at a washing temperature of 70 °C; then the silica wet gel beads were soaked in absolute ethanol 4 times, 2 h each time, and the aging temperature was 55°C; finally soak the silica wet gel pellets in n-hexane for 4 times, 3 h each time, at a temperature of 35°C; dry the silica wet gel pellets in a desiccator at 30°C to prepare Silica airgel pellets were obtained.

Embodiment 3

[0037] Measure 1.3 mL of glacial acetic acid in a beaker for later use; weigh 8 g of water glass in a beaker, measure 50 mL of cooled deionized water to dilute the water glass for later use; under stirring, drop the water glass into hydrochloric acid, the solution pH About 5.8. The prepared sol was added dropwise into simethicone oil at 85° C. at a height of 15 cm to form silica wet gel beads. The prepared silica wet gel beads were washed with water three times, each time for 2 h, at a washing temperature of 50 °C; then, the silica wet gel beads were soaked in absolute ethanol for four times, each time for 2 h, and the aging temperature was 50°C; transfer the silica wet gel beads to the ethanol solution of tetraethyl orthosilicate and soak for 48 h at a temperature of 55°C; finally soak the silica wet gel beads in n-hexane for 3 times, The immersion temperature was 45°C for 4 hours each time; the silica airgel pellets were prepared by drying the silica wet gel pellets in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com