Industrial catalyst for preparing ethanol with acetic ester by hydrogenation, preparation method of industrial catalyst and application

A catalyst, acetate technology, applied in chemical instruments and methods, hydroxyl compound preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of metal chromium environment unfriendly, low ethanol selectivity, catalyst cost Advanced problems, to achieve the effect of simple preparation method, high selectivity, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

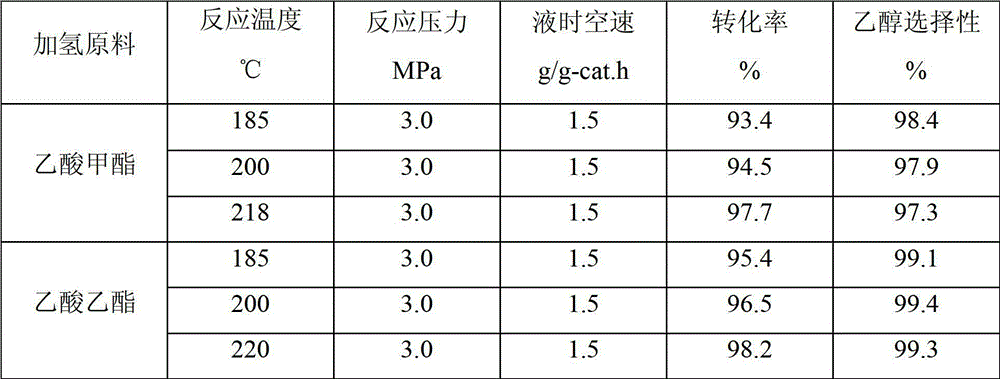

Embodiment 1

[0041] Preparation of industrial catalysts for the hydrogenation of acetate to ethanol:

[0042] (1) 1.5 liters of copper nitrate solution (the content of Cu is 8%wt), and 300 grams of Zn(NO 3 ) 2 .6H 2 O, add 50 g Mg(NO 3 ) 2 .6H 2 O is dissolved, diluted with deionized water to a total metal ion concentration of 0.2mol / L, and the pH of the solution is <2;

[0043] (2) After dissolving 300 grams of sodium carbonate in deionized water, add 0.6 liter of 25wt% silica sol, and then dilute to a carbonate concentration of 0.2mol / L, and the pH of the solution is >11;

[0044] (3) Under stirring, add the above two solutions dropwise into the reaction kettle to carry out the precipitation reaction. The reaction temperature is 70°C. After the solution is added dropwise, continue to keep warm and stir for 1 hour, and the pH value of the kettle liquid is >7;

[0045] (4) After the reaction is completed, wash repeatedly with deionized water and filter until the filtrate is neutral a...

Embodiment 2

[0053] Preparation of acetate hydrogenation catalyst:

[0054] (1) 1.5 liters of copper nitrate solution (the content of Cu is 8%wt), and 250 grams of Zn(NO 3 ) 2 .6H 2 O, add 30 g Co(NO3 ) 2 .6H 2 O is dissolved, diluted with deionized water to a total metal ion concentration of 0.2mol / L, and the pH of the solution is <2;

[0055] (2) After dissolving 300 grams of sodium carbonate in deionized water, add 0.6 liter of 25wt% silica sol, and then dilute to a carbonate concentration of 0.2mol / L, and the pH of the solution is >11;

[0056] (3) Under stirring, add the above two solutions dropwise into the reaction kettle to carry out the precipitation reaction. The reaction temperature is 70°C. After the solution is added dropwise, continue to keep warm and stir for 1 hour, and the pH value of the kettle liquid is >7;

[0057] (4) After the reaction is completed, wash repeatedly with deionized water and filter until the filtrate is neutral and the conductivity is <1000μs / cm; t...

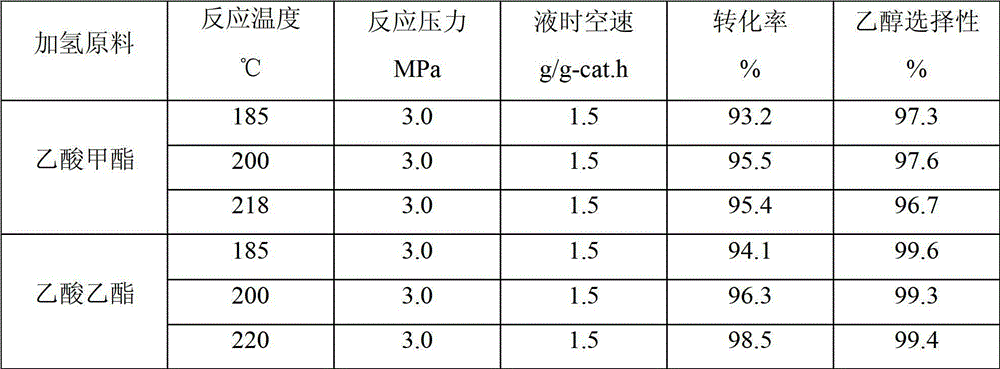

Embodiment 3

[0065] Preparation of industrial catalysts for the hydrogenation of acetate to ethanol:

[0066] (1) 1.5 liters of copper nitrate solution (the content of Cu is 8%wt), and 200 grams of Zn(NO 3 ) 2 .6H 2 O, add 40 g Ca(NO 3 ) 2 .4H 2 O is dissolved, diluted with deionized water to a total metal ion concentration of 0.2mol / L, and the pH of the solution is <2;

[0067] (2) After dissolving 300 grams of sodium carbonate in deionized water, add 0.6 liter of 25%wt silica sol, and then dilute until the concentration of carbonate is 0.2mol / L, and the pH value of the solution is >11;

[0068] (3) Under stirring, add the above two solutions dropwise into the reaction kettle to carry out the precipitation reaction. The reaction temperature is 80°C. After the solution is added dropwise, continue to keep warm and stir for 1 hour, and the pH value of the kettle liquid is >7;

[0069] (4) After the reaction is completed, wash repeatedly with deionized water and filter until the filtrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com