Catalyst for producing synthesis gas by reforming natural gas-carbon dioxide for industry

A carbon dioxide and catalyst technology, applied in the field of industrial catalysts, can solve the problems of catalyst carbon deposition and inability to industrialize, and achieve the effects of stable catalyst performance, strong anti-carbon deposition and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Raw material: nickel nitrate: Ni(NO 3 ) 2· 6H 2 o

[0037] Lanthanum nitrate: La(NO 3 ) 3· 6H 2 o

[0038] Citric acid: HO 2 CCH 2 (OH)(CO 2 H)CH 2 CO 2 h

[0039] Ethylene glycol: HOCH 2 CH 2 Oh

[0040] Aluminum glue: AlOOH

[0041] Prepare a certain concentration of Ni(NO 3 ) 2 and La(NO 3 ) 3 The mixed aqueous solution, and then add citric acid and ethylene glycol solution of 1.5 times the concentration of metal ions. Stir for 20 hours under the condition of 50-60 degrees Celsius to obtain a green transparent gel. The gel is aged at a constant temperature for 2-3 days, and then foamed and dried in an oven at 70-80° C. for 20 hours under normal pressure. That is, the precursor of a porous Ni-based catalyst is obtained. The precursor is calcined in the air at 500° C. for 6 hours to prepare the nano-particle Ni-La powder catalyst. The catalyst is ground, mixed with 10% aluminum glue, and then processed into In the catalyst for industrial use, t...

Embodiment 2

[0047] According to the same method as in Example 1, mix La(NO 3 ) 3 and Ni(NO 3 ) 2 solution, adding a small amount of RuCl 3 or RhCl 3 Dissolve in the mixed solution, and then add organic reagents such as citric acid with 1.5 times the concentration of metal ions.

[0048] Stir at 60°C for more than 10 hours to form a uniform transparent Ni-M-La sol (M=Ru and / or Rh). Aging at room temperature for 4-5 days, foaming and drying in an oven at 110-120°C for 10 hours under normal pressure. Then bake in a muffle furnace at 800 DEG C for 6 hours to prepare a nickel-based nano-catalyst containing noble metal Ru or Rh (0.01-2%). Then prepare according to the same method as in Example 1 The cylindrical industrial catalyst has the weight percentage of each component: 9-15% of Ni, 17-35% of La and 0.4% of Ru.

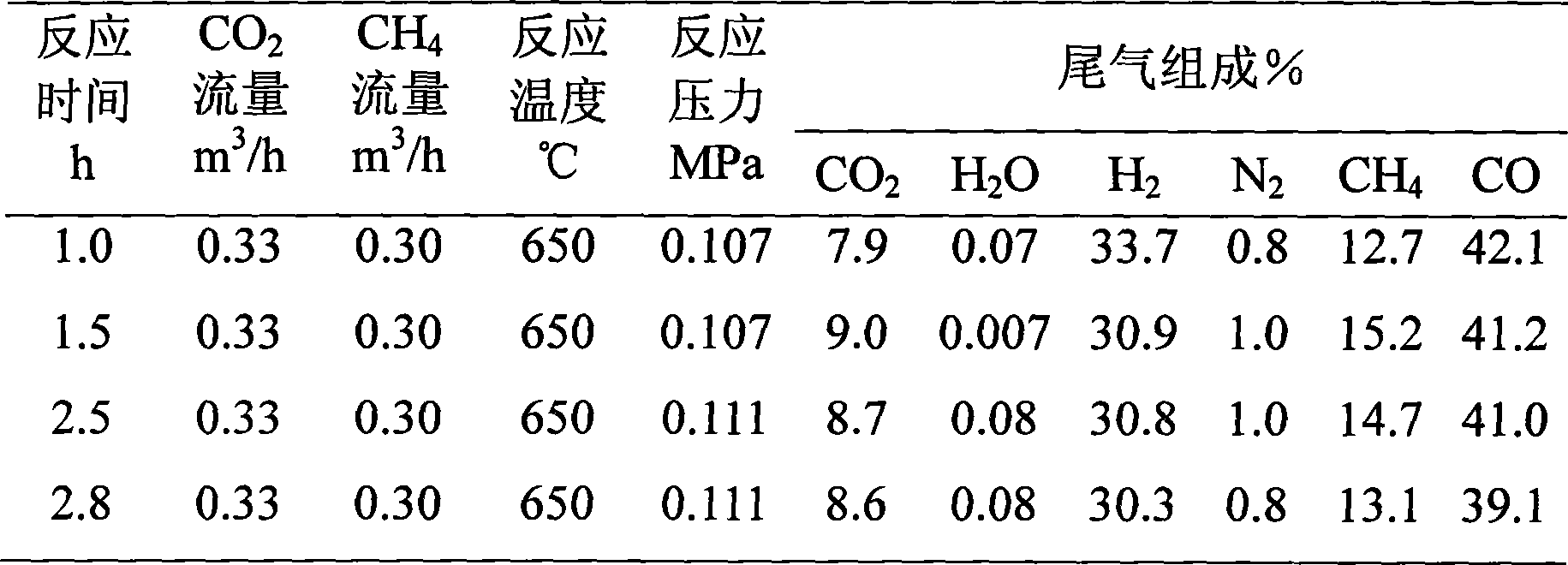

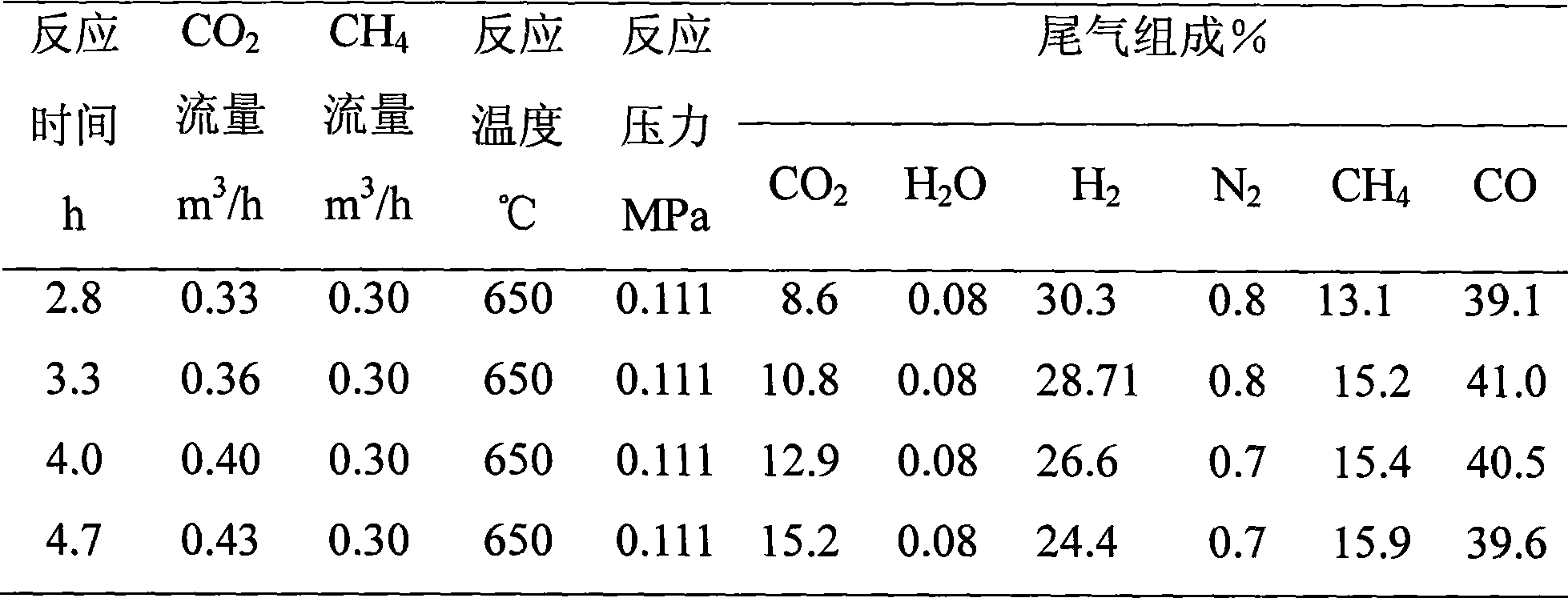

[0049] In the evaluation of catalyst activity, the commercially scaled-up catalyst was crushed into granular catalysts with a diameter of about 1-2 mm. Before the reacti...

Embodiment 3

[0054] According to the same method as in Example 1, La(NO 3 ) 3 and Ni(NO 3 ) 2 Inject the mixed solution of 200g of commercially available ZSM-5 molecular sieves (purchased from Nankai University Catalyst Factory), impregnate for 5 hours under constant stirring, then add citric acid and ethylene glycol with 1.5 times the metal ion concentration, and stir at 60°C Make a gel containing ZSM-5 carrier. Then aging according to the method of Example 1, foaming and drying in an oven, and finally calcining at 550° C. for 6 hours in a muffle furnace to obtain a supported catalyst containing 9% (weight ratio) of nickel. Then prepare 9%Ni-La / ZSM-5 industrial catalyst according to the method of embodiment 1 The weight percent content of each component is: Ni9%, La40-46%, and the rest are carrier, adhesive and auxiliary agent.

[0055] Pack 0.3 kg of industrial catalyst in the industrial scale-up reactor. The catalyst was heated at 850°C in 20% H 2 / N 2 Reduction in the mixed ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com