Method for proceeding Feituo Synthesizing reaction and catalyst specially for the same

一种催化剂、纳米催化剂的技术,应用在有机化合物/氢化物/配位配合物催化剂、物理/化学过程催化剂、催化反应等方向,能够解决总压力苛刻、产物分子量大等问题,达到好低温活性、广阔应用前景的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

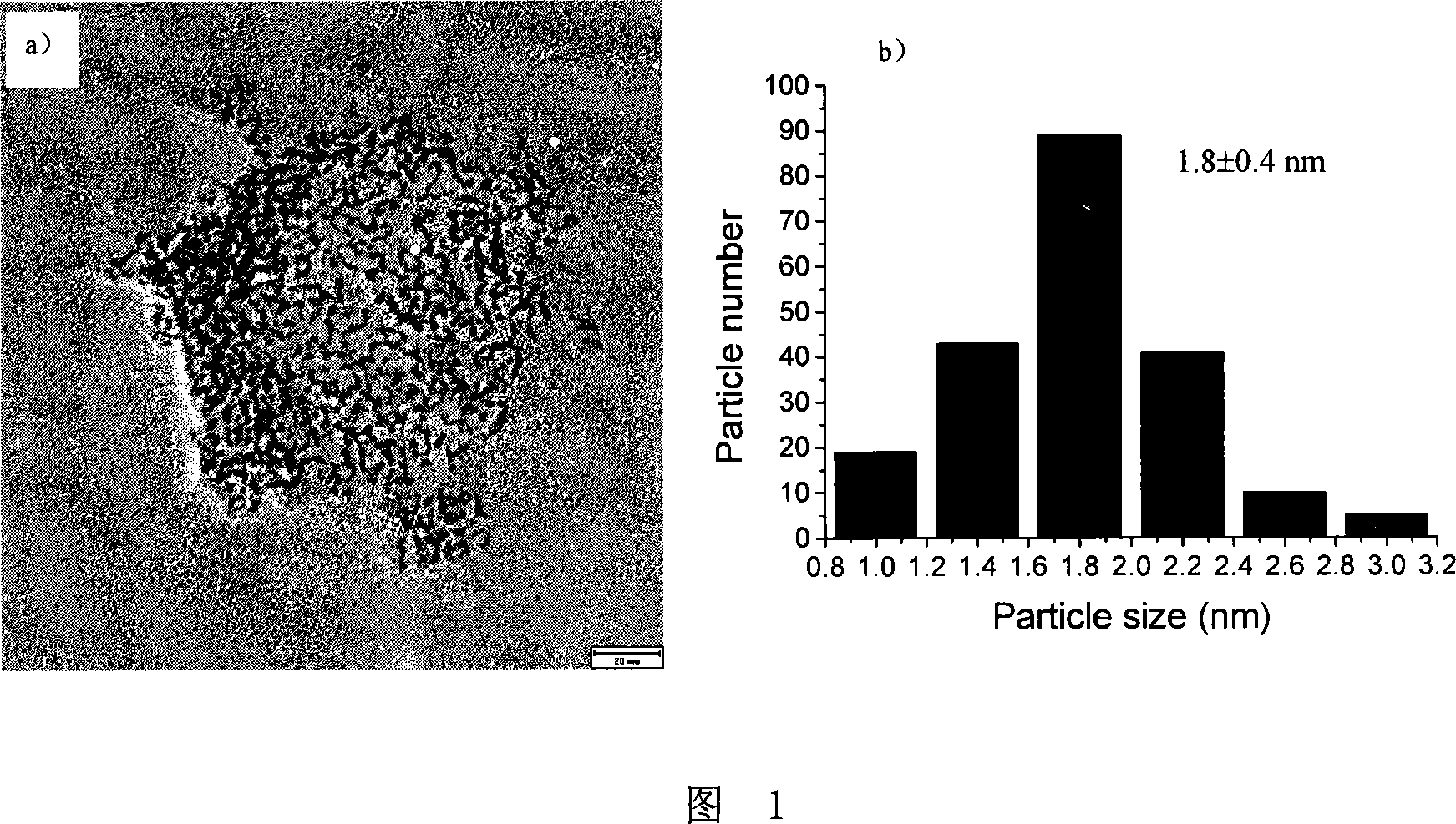

[0023] 73mg RuCl 3 ·nH 2 O and 620mg of polyvinylpyrrolidone (polyvinylpyrrolidone: Ru=20, molar ratio, the same below) were added to 20ml of water, stirred and mixed, and then added to a 60ml autoclave at 150°C, 20atm H 2 The catalyst for the reaction was obtained by reducing it for 2 hours. The prepared ruthenium nanoparticles have an average particle size of 1.8±0.4nm, and the transmission electron micrographs and particle size distribution of the ruthenium nanoparticles are shown in Figure 1a and Figure 1b, respectively.

[0024] Cool the catalyst to room temperature, release residual gas, and then fill with 10atm CO, 20atm H 2 , react at 150°C. The reaction results are shown in Table 1.

Embodiment 2

[0026] 73mg RuCl 3 ·nH 2 O and 106mg of polyvinylpyrrolidone (polyvinylpyrrolidone: Ru=3.4) were added to 20ml of 1,4-dioxane, stirred and mixed, and then added to a 60ml autoclave at 150°C, 20atmH 2 The catalyst for the reaction was obtained by reducing it for 2 hours. Cool to room temperature, release residual gas, fill with 10atmCO, 20atmH 2 , react at 150°C. The reaction results are shown in Table 1.

Embodiment 3

[0028] 73mg RuCl 3 ·nH 2 O and 106mg of polyvinylpyrrolidone (polyvinylpyrrolidone: Ru=3.4) were added to 20ml of ethanol, stirred and mixed, and then added to a 60ml autoclave at 150°C, 20atmH 2 The catalyst for the reaction was obtained by reducing it for 2 hours. Cool to room temperature, release residual gas, fill with 10atm CO, 20atm H 2 , react at 150°C. The reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com