Process for synthesizing nano-lead from waste cathode-ray tube (CRT) lead-containing glass by one-step method

A cathode ray tube and cathode ray technology, applied in the field of waste resource recycling, can solve the problems of high technical equipment requirements, long processing time, high energy consumption, etc., and achieve the effect of broad application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

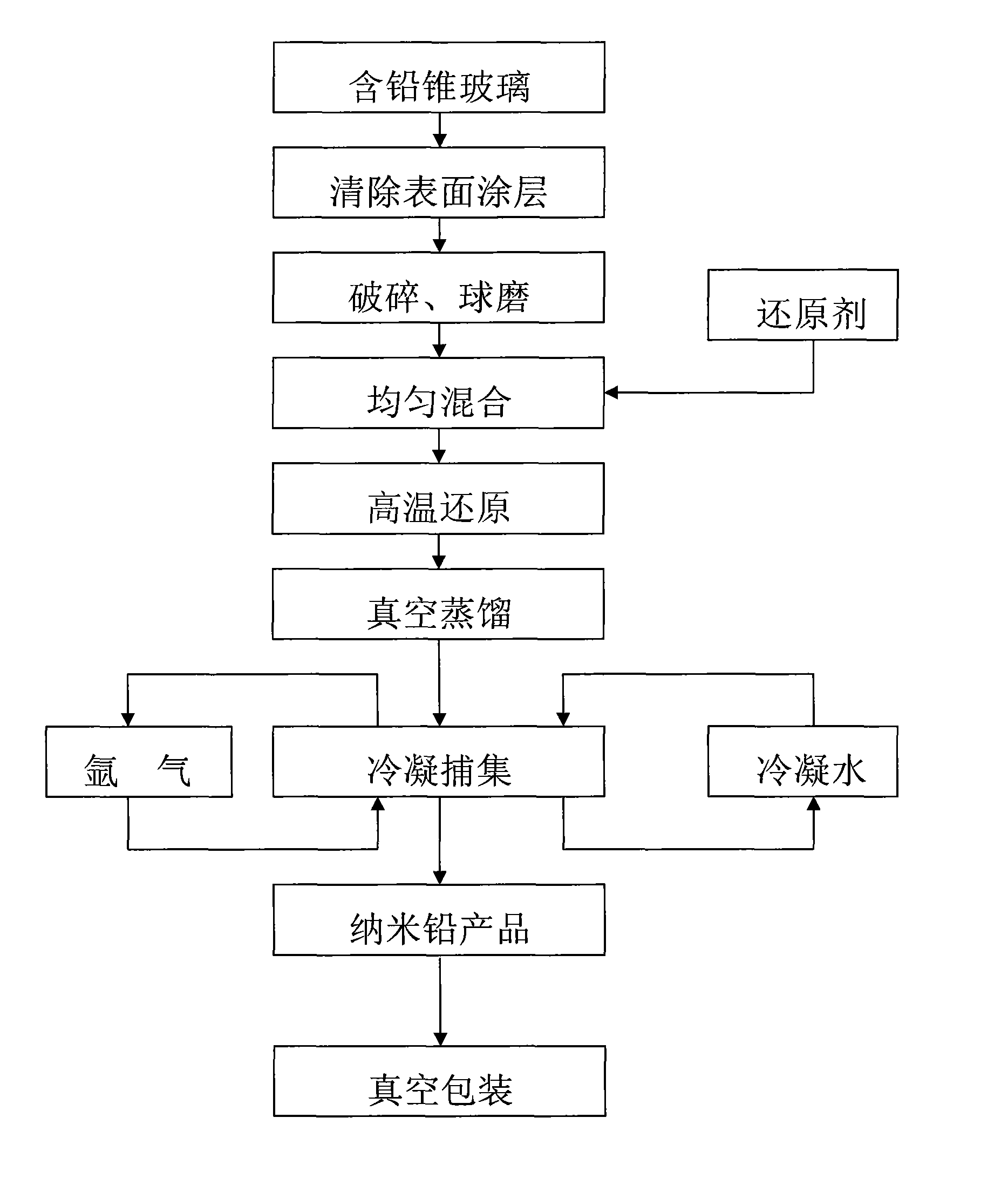

[0017] A process for synthesizing nano-lead in one step from leaded glass in waste cathode ray tubes, specifically comprising the following steps:

[0018] Such as figure 1 As shown, after removing the iron oxide layer and graphite layer on the inner and outer layers of the lead-containing cone glass, use a planetary ball mill to grind the cone glass to 200 mesh, and then put the cone glass powder and 200-mesh carbon powder in the ball mill according to the mass ratio of 9:1 Ball mill to mix evenly. Weigh 5 grams of uniformly mixed powder in the quartz boat, then put the quartz boat into the vacuum furnace, and pass an appropriate amount of argon to remove the oxygen in the furnace. After the oxygen is removed, close the argon valve and open the vacuum furnace temperature riser to The furnace body is heated at a rate of 15°C / min. After the temperature in the furnace reaches 1000°C, open the vacuum device, the argon gas valve and the cooling water, control the temperature in ...

Embodiment 2

[0020] A process for synthesizing nano-lead in one step from leaded glass in waste cathode ray tubes, specifically comprising the following steps:

[0021] Such as figure 1 As shown, after removing the iron oxide layer and graphite layer on the inner and outer layers of the cone glass, use a planetary ball mill to grind to 200 mesh, and then mix the glass powder and 200 mesh carbon powder in the ball mill according to the mass ratio of 10:1. Weigh 500 grams of uniformly mixed powder in a high-temperature-resistant stainless steel container, then put it into a vacuum furnace, pass an appropriate amount of argon to remove the oxygen in the furnace, close the argon valve after the oxygen is removed, and open the vacuum furnace temperature riser to 15 The furnace body is heated at a rate of ℃ / min. After the furnace temperature reaches 1000°C, open the vacuum device, argon gas valve and cooling water, control the furnace temperature at 1000°C, vacuum degree of 1000Pa, distillation...

Embodiment 3

[0023] A process for synthesizing nano-lead in one step from leaded glass in waste cathode ray tubes, specifically comprising the following steps:

[0024] (1) Pre-treatment process: Use negative pressure suction and desorption technology to remove the iron oxide layer and graphite layer on the inner and outer layers with high lead content, and then use a jaw crusher to crush the cone glass into less than 2 mm granular, and then use a planetary ball mill to grind the glass particles to about 200 mesh.

[0025] (2) Batching process: add carbon powder into the ball mill, the mass ratio of glass powder and carbon powder is 8:1, continue ball milling, so that the fineness of the mixture reaches about 200 mesh.

[0026] (3) Heat treatment process: Take 2 kg of the prepared mixture and put it into a vacuum furnace, pass argon gas to remove the oxygen in the furnace, close the argon valve and open the vacuum furnace heating device after the oxygen is removed, at a rate of 10 °C / min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com