High-performance subcarbonate electrolyzed water catalyst as well as preparation method and application thereof

A technology for electrolyzing water and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, electrolysis processes, etc., can solve problems such as price difference, catalyst activity needs to be improved, stability limitations, etc., and achieve low cost and excellent electrolysis Hydrogen evolution performance of water, oxygen evolution performance of electrolyzed water, and effect of low industrial production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

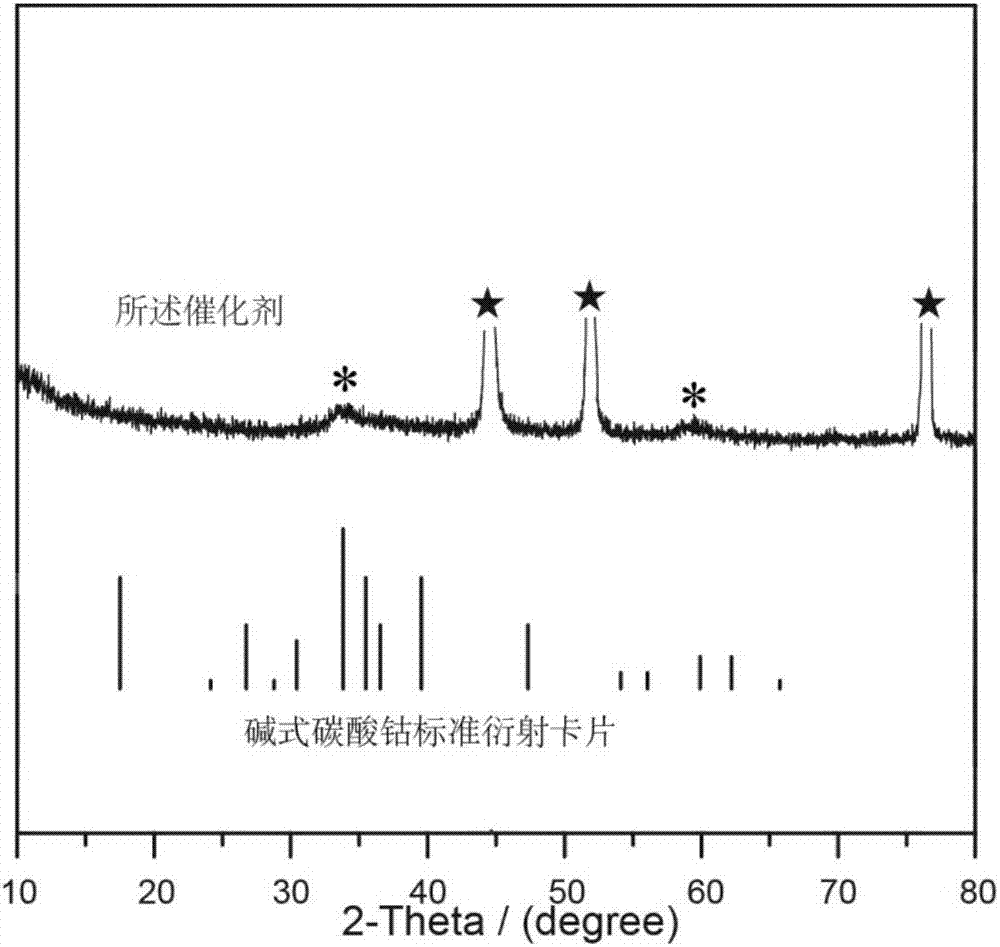

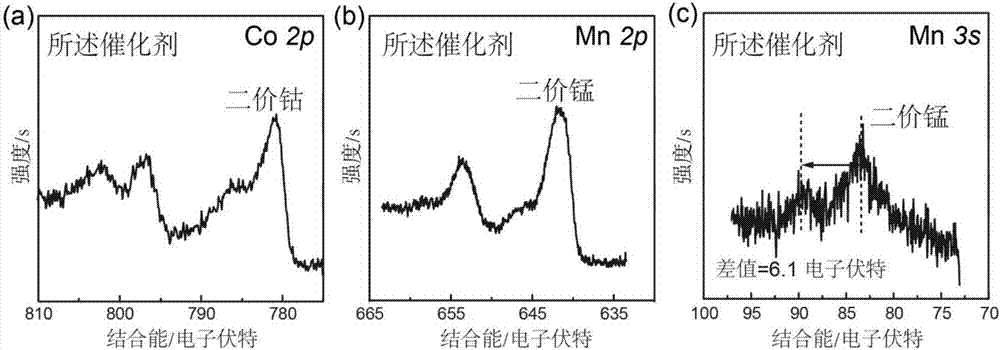

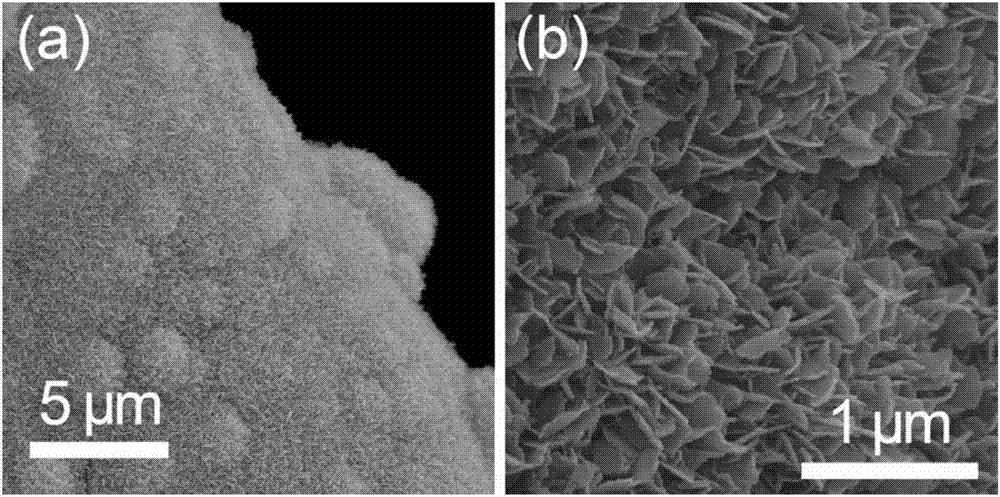

[0035] Embodiment 1, preparation cobalt manganese basic carbonate electrolytic water catalyst

[0036] 2 mmol of cobalt acetate, 2 mmol of manganese acetate and 250 mg of hexamethylenetetramine were dissolved in a mixed solution of 13 ml of ethylene glycol and 14 ml of ethanol, and uniformly stirred for 30 minutes to obtain a uniform and clear solution. Then transfer this solution to a 50 ml polytetrafluoroethylene reactor, and place a 2 cm x 4 cm foamed nickel substrate in it, then tighten the outer lining of the reactor, and place it in an oven to heat it to 170 degrees Celsius And keep it warm for 8 hours, stop heating and cool down to room temperature naturally, take out the nickel foam in the reactor and rinse it with ethanol for 3 times and then place it in a vacuum drying oven and dry it for 6 hours to obtain the cobalt-manganese basic carbonate with uniform growth. Nickel foam with nanosheet arrays can be directly used in electrodes for total water splitting.

[0037]...

Embodiment 2

[0056] Embodiment 2, preparation basic cobalt carbonate electrolysis water catalyst

[0057] Basically prepare the electrolytic water catalyst according to the same method as in Example 1, the difference is that the cobalt-manganese metal ratio is changed to cobalt: manganese-1:0, and the obtained catalyst is a flower-shaped cobalt basic carbonate nanosheet array. Structure grown on nickel foam; total water splitting was tested in 1 molar potassium hydroxide solution to give a potential of 1.75 volts at 10 milliamperes per square centimeter.

Embodiment 3

[0058] Embodiment 3, preparation iron cobalt basic carbonate electrolytic water catalyst

[0059] Prepare electrolytic water catalyst basically according to the same method as Example 1, difference is that manganese acetate is replaced by iron acetate, and the catalyst obtained is that the array array of iron-cobalt basic carbonate nanosheet grows on foamed nickel; 10 milliamperes per square centimeter corresponds to a potential of 1.70 volts when tested for total water decomposition in 1 mole per liter of potassium hydroxide solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com