A kind of carbon-coated cobalt and cobalt oxide composite nanomaterial and its preparation method and application

A technology of composite nanomaterials and composite nanostructures, applied in electrolytic components, electrodes, electrolytic processes, etc., can solve the problems of preparing metal cobalt and its oxide nanoparticles, low stability, etc., and achieve excellent electrolytic water hydrogen evolution performance, The effect of good stability and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

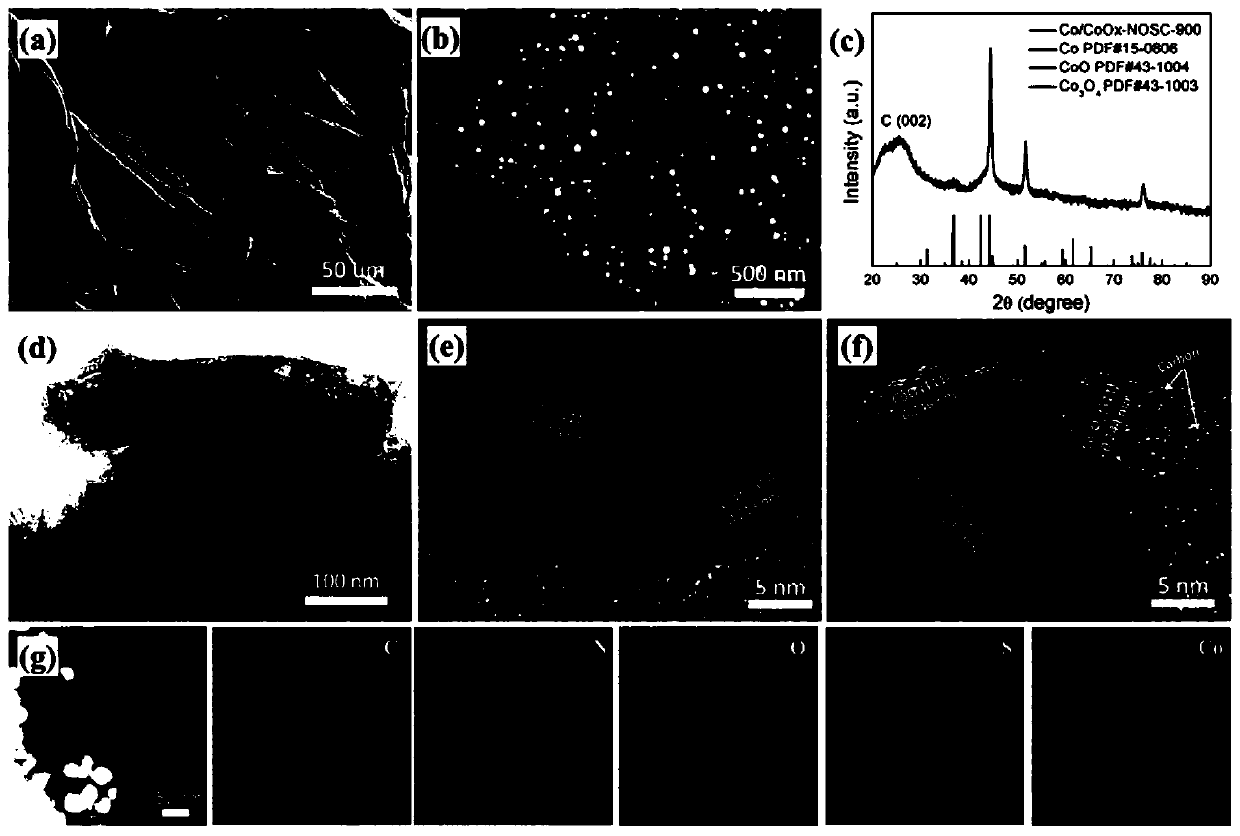

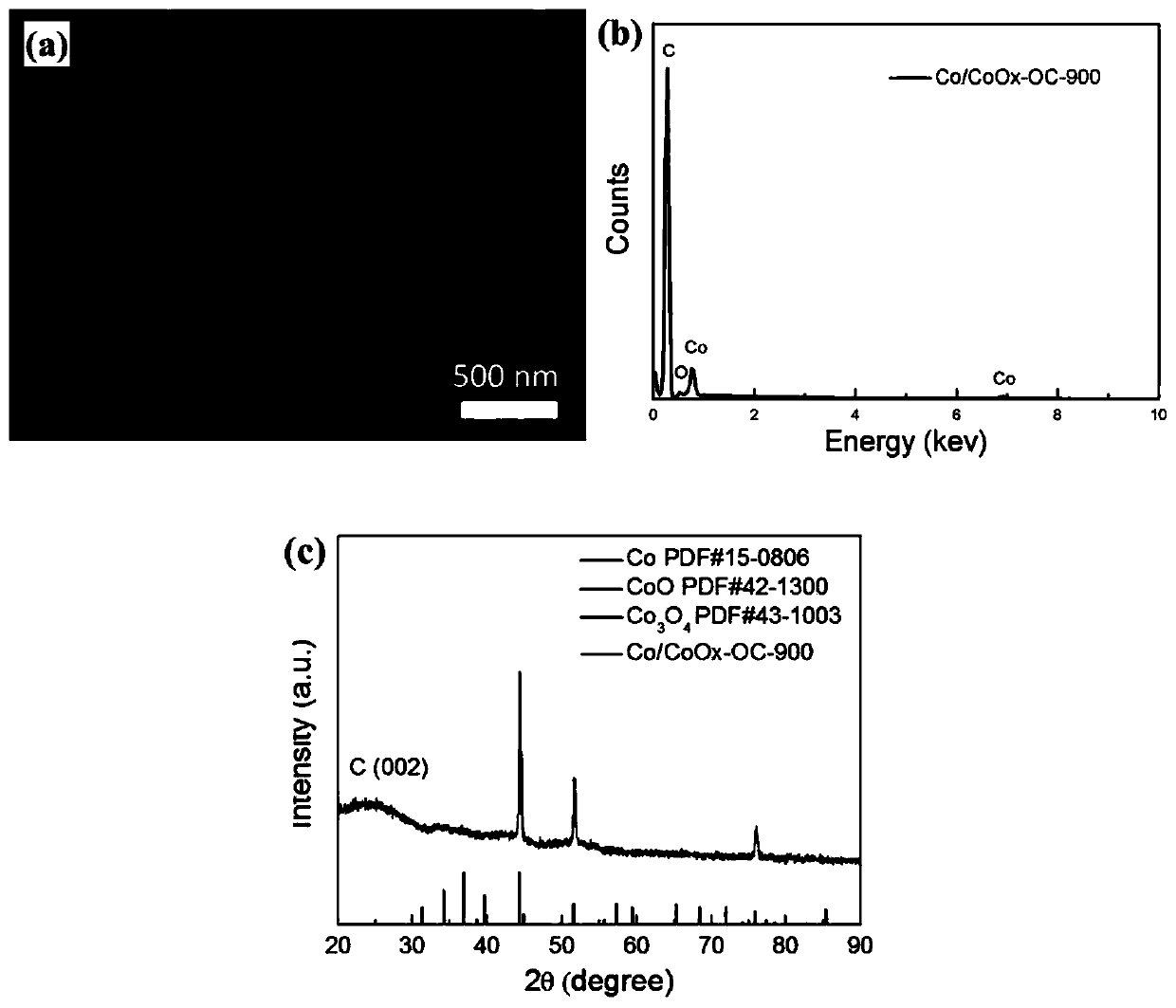

[0028] Specifically, the preparation method of carbon-coated cobalt and cobalt oxide composite nanomaterials provided by the present invention includes:

[0029] Step A. Soak the clean and dry filter paper in the mixed solution of cobalt chloride and thiourea for 3 hours. After the filter paper is saturated with adsorption, take out the filter paper and dry it to obtain the saturated filter paper after drying. . Wherein, the mixed solution of described cobalt chloride and thiourea is made of cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and thiourea (CH 4 N 2 S) made by dissolving in water, and every 2cm 2 The required consumption of cobalt chloride hexahydrate for the filter paper is 0.3~0.6g, the required consumption of thiourea is 0.5~1.5g, and the required consumption of water is 10 milliliters. The drying treatment may include firstly absorbing the liquid on the surface of the filter paper with toilet paper, and then performing drying treatment in an oven at 50°C. In...

Embodiment 1

[0040] A carbon-coated cobalt and an oxide composite nanomaterial of cobalt, the preparation method of which may comprise the following steps:

[0041] Step a. Cut the filter paper into rectangular paper strips of 1cm×2cm, soak in ethanol solution and ultrasonically clean for 30 minutes, take out after repeated cleaning three times, and then dry in an oven at 60°C to obtain clean and dry filter paper.

[0042] Step b, 0.3~0.6g cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and 0.5~1.5g thiourea (CH 4 N 2 S) was dissolved in 10 ml of water to prepare a mixed solution of cobalt chloride and thiourea.

[0043] Step c, soak the clean and dry filter paper described in step a in the mixed solution of cobalt chloride and thiourea described in step b, soak for 3 hours, after the filter paper is saturated with adsorption, take out the filter paper, and use toilet paper The liquid on the surface of the filter paper was blotted dry, and then dried in an oven at 50°C. Thereby obtaining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com