A carbon-coated Fe-doped nise nanomaterial with excellent electrolytic water oxygen evolution performance and its preparation method

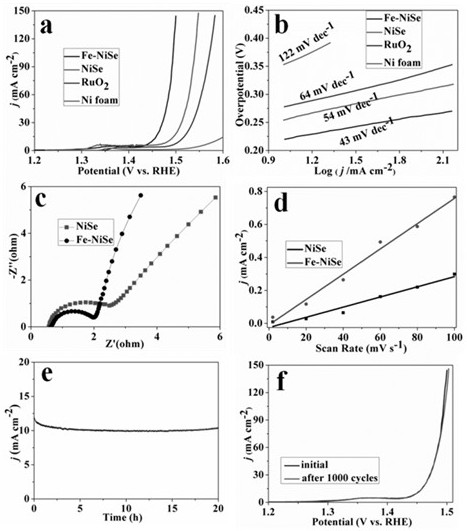

A technology of electrolysis of water and carbon coating, applied in the direction of electrolysis components, electrolysis process, chemical instruments and methods, etc., can solve the problems of easy dissolution, poor conductivity, few active sites, etc., and achieve easy adsorption of reactants and good stability , the effect of more active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

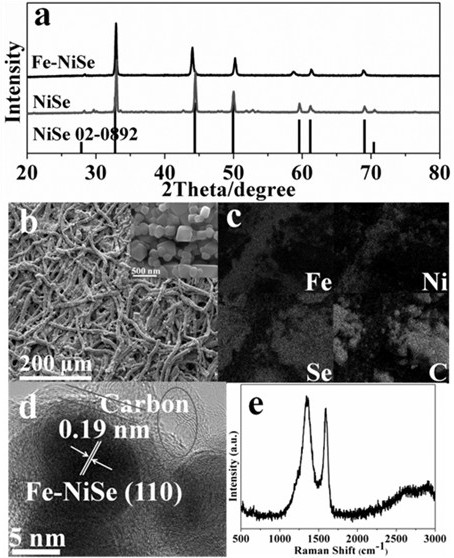

[0023] 0.5 g of ferric nitrate (Fe(NO 3 ) 3 9H 2 O) and 1.0 g of nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) Add it into 10 ml of water, dissolve it into a uniform mixed solution, then soak the cleaned filter paper in the mixed solution for 2 hours, take out the filter paper after the adsorption is saturated, and use toilet paper to absorb the excess solution on the surface, dry it with 0.5 Put gram of selenium powder together into a tube furnace, under nitrogen atmosphere, first heat to 450 degrees Celsius for 2 hours, then heat to 750 degrees Celsius for 2 hours, then cool down to room temperature naturally to get Fe-NiSe composite electrolytic water oxygen evolution catalyst .

Embodiment 2

[0025] 1.0 g of ferric nitrate (Fe(NO 3 ) 3 9H 2 O) and 2.0 grams of nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) Add it into 20 ml of water, dissolve it into a uniform mixed solution, then soak the cleaned filter paper in the mixed solution for 2 hours, take out the filter paper after the adsorption is saturated, and use toilet paper to absorb the excess solution on the surface, dry it and mix it with 0.5 Put gram of selenium powder together into a tube furnace, under nitrogen atmosphere, first heat to 450 degrees Celsius for 2 hours, then heat to 750 degrees Celsius for 2 hours, then cool down to room temperature naturally to get Fe-NiSe composite electrolytic water oxygen evolution catalyst .

Embodiment 3

[0027] 0.5 g of ferric nitrate (Fe(NO 3 ) 3 9H 2 O) and 1.0 g of nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) Add it into 10 ml of water, dissolve it into a uniform mixed solution, then soak the cleaned filter paper in the mixed solution for 1 hour, take out the filter paper after the adsorption is saturated, and absorb the excess solution on the surface with toilet paper, dry it and mix it with 0.5 Put gram of selenium powder together into a tube furnace, under nitrogen atmosphere, first heat to 450 degrees Celsius for 2 hours, then heat to 750 degrees Celsius for 2 hours, then cool down to room temperature naturally to get Fe-NiSe composite electrolytic water oxygen evolution catalyst .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com