Composite metal salt catalyst for acetylene hydrochlorination

A composite metal salt, acetylene hydrochlorination technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, organic chemistry, etc. Loss, catalyst carbon deposition and other problems, to achieve the effect of improving catalyst life, broad application potential, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

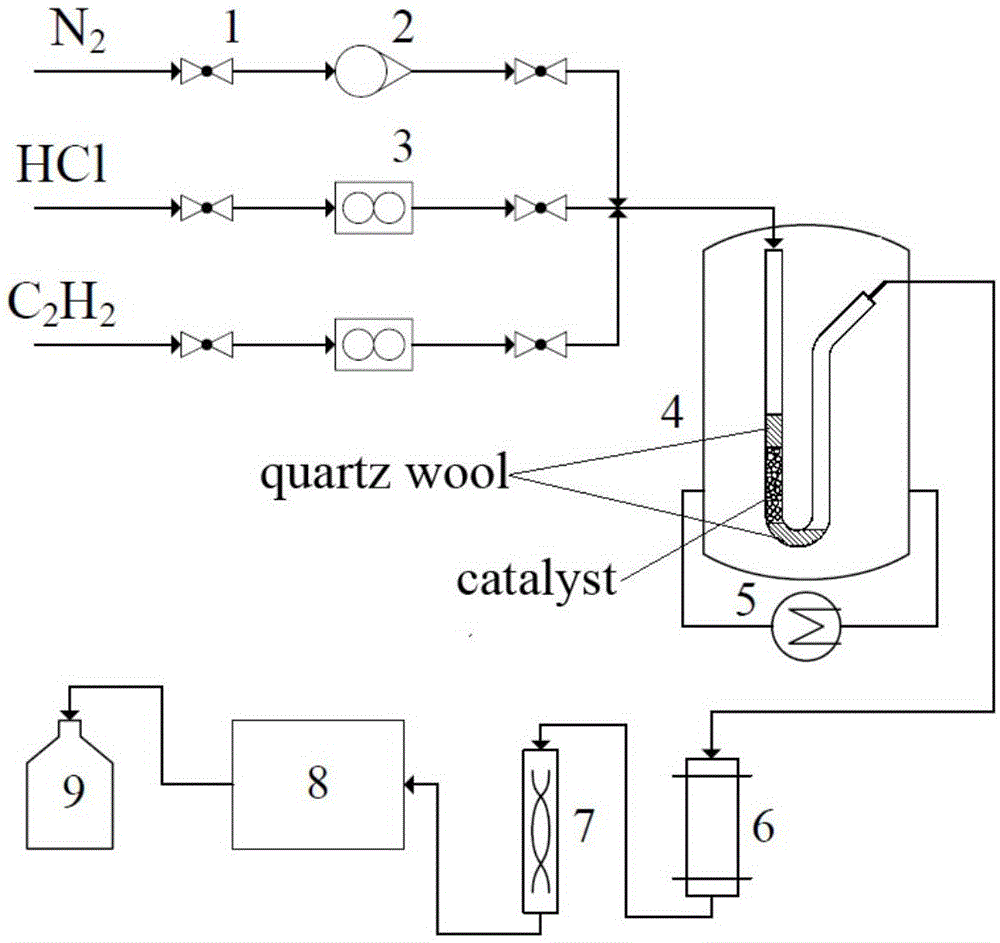

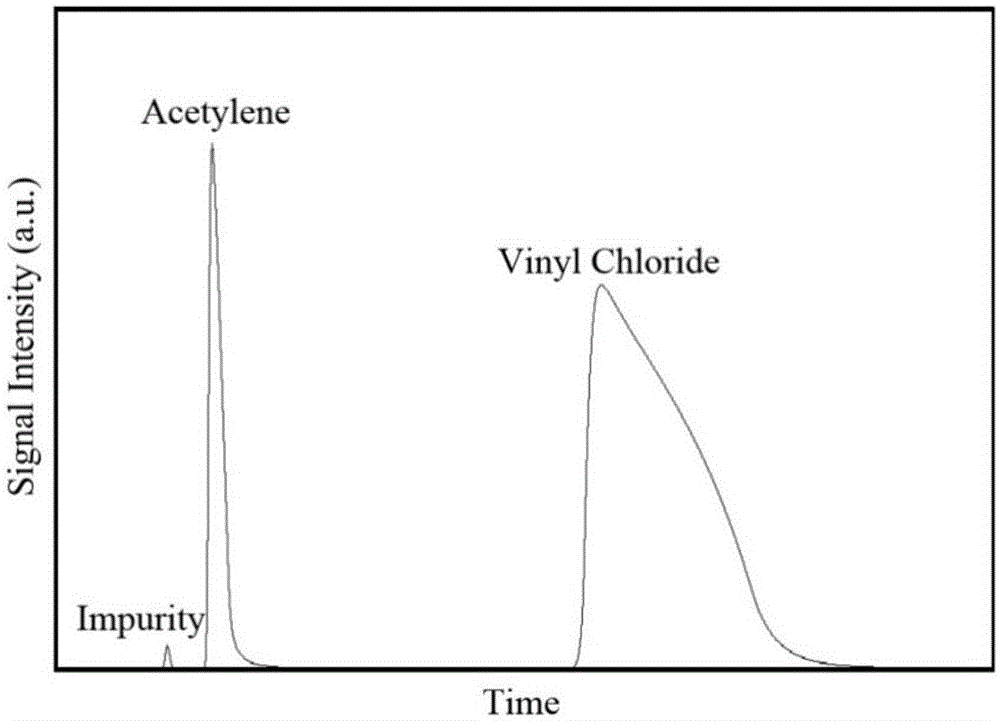

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: with coconut shell charcoal as carrier, cupric chloride is active component preparation catalyst, and adds cooperative metal potassium, wherein the load of copper is 5wt% (mass fraction), the load of potassium is 0.77wt%-3.08wt %. The reaction was carried out under the above reaction conditions, and the initial conversion rate of the catalyst and the decline value of the conversion rate of the catalyst within 12 hours were recorded in Table 1.

Embodiment 2

[0029] Embodiment 2: with coconut shell charcoal as carrier, cupric chloride is active component preparation catalyst, and adds cooperative metal zirconium, wherein the load of copper is 5wt% (mass fraction), the load of zirconium is 1.80wt%-7.18wt %. The reaction was carried out under the above reaction conditions, and the initial conversion rate of the catalyst and the decline value of the conversion rate of the catalyst within 12 hours were recorded in Table 1.

Embodiment 3

[0030] Embodiment 3: with coconut shell charcoal as carrier, cupric chloride is active component preparation catalyst, and adds cooperative metal lanthanum, wherein the load of copper is 5wt% (mass fraction), the load of lanthanum is 2.74wt%-10.92wt %. The reaction was carried out under the above reaction conditions, and the initial conversion rate of the catalyst and the decline value of the conversion rate of the catalyst within 12 hours were recorded in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com