Dendritic golden nanophase material and preparation method thereof

A dendritic, gold nanotechnology, applied in the field of preparation of precious metal nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

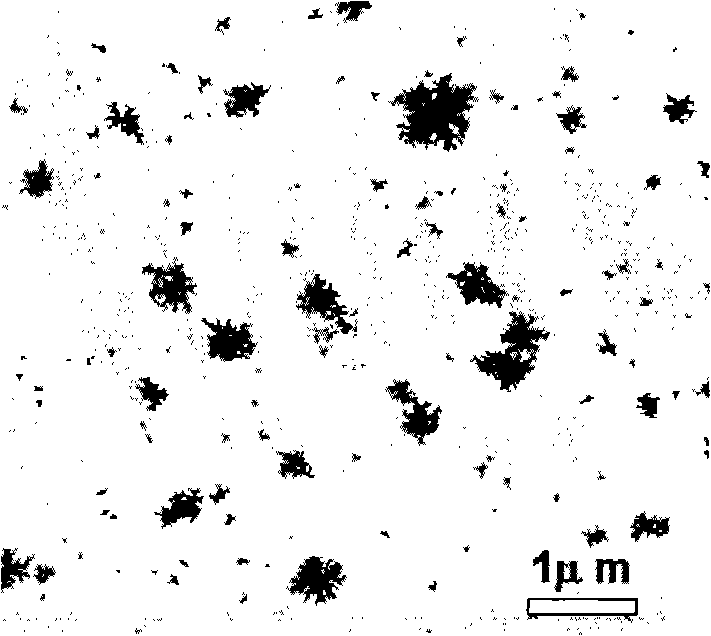

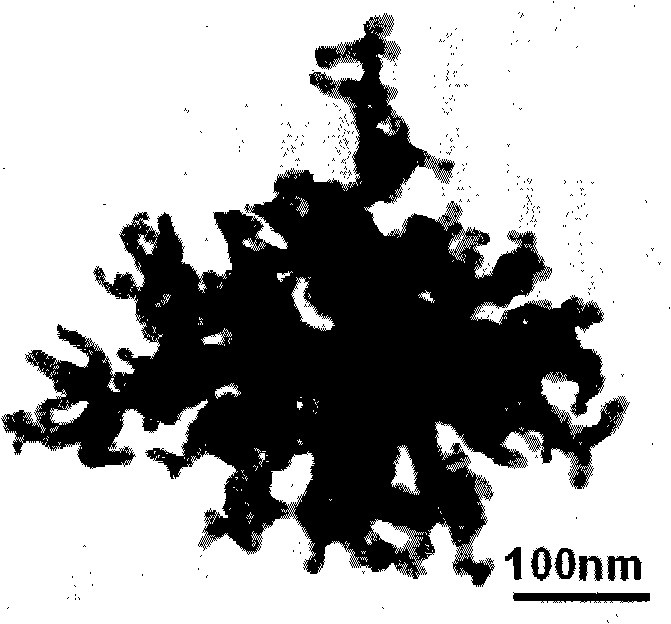

[0031] In this embodiment, a multi-branched dendritic gold nanomaterial is prepared, the size range of which is 100-500 nanometers, such as Figure 1a with Figure 1b For the transmission electron microscope pictures of the dendritic gold nanostructures prepared, it can be seen that each gold branch of the dendritic gold nanomaterial is bonded and fused with each other through gold nanoparticles or forms a twin structure growth (see Figure 3a , Figure 3b , Figure 3c , Figure 3d ), there are nano-scale gaps between the gold branches, and the surface of the dendritic gold nanostructure is wrapped by polyvinylpyrrolidone polymer.

[0032] The specific preparation method includes the following steps:

[0033] (1) Choose chloroauric acid (HuAuCl4·3H2O) or chloroauric acid (MAuCl4·XH2O) for the reaction system, for example, chloroauric acid potassium; ammonium formate (Ammonium Formate) and stabilizer polyvinylpyrrolidone (PVP) , The three are reactants, and deionized water is the s...

Embodiment 2

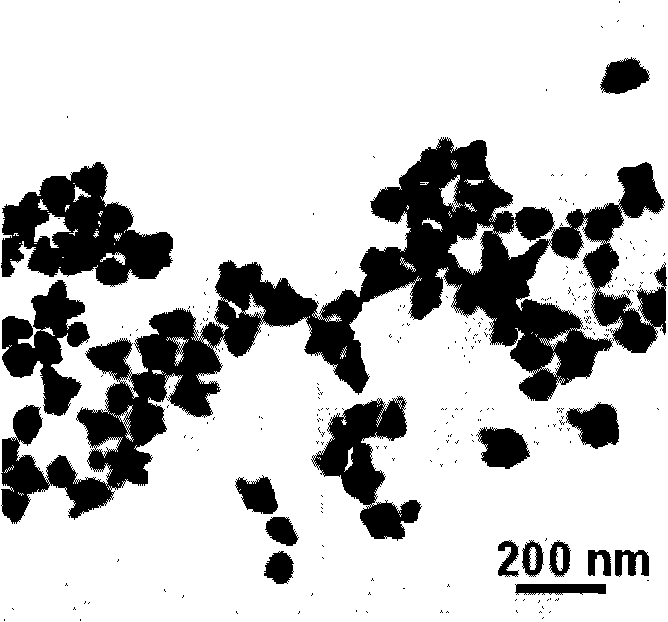

[0038] In this embodiment, a few branched dendritic gold nanostructures are prepared, and the size range is 100-200 nanometers, such as Figure 2a with Figure 2b For the transmission electron microscope picture of the prepared dendritic gold nanostructures, it can be seen that each gold branch of the dendritic gold nanomaterial is bonded to each other by gold nanoparticles to form a twin structure growth (see Figure 2c , Figure 2d ), there are nano-scale gaps between the gold branches, and the surface of the dendritic gold nanostructure is wrapped by polyvinylpyrrolidone polymer.

[0039] The specific preparation method includes the following steps:

[0040] (1) The reaction system chooses chloroauric acid (HuAuCl4·3H2O) or sodium chloroauric acid, ammonium formate (Ammonium Formate) and polyvinylpyrrolidone (PVP) stabilizer as the reactants, and the water phase is the solvent; among them, chloroauric acid Or 0.18mmol of chloroauric acid, 0.2g of polyvinylpyrrolidone, 0.34g of ...

Embodiment 3

[0045] In this embodiment, preliminary branched gold nanostructures are prepared, and the size range is 100-200 nanometers, such as Figure 5a with Figure 5b For the transmission electron microscope pictures of the dendritic gold nanostructures prepared, it can be seen that each gold branch of the dendritic gold nanomaterial is bonded and fused with each other through gold nanoparticles or forms a twin structure growth (see Figure 5c , Figure 5d ), there are nano-scale gaps between the gold branches, and the surface of the dendritic gold nanostructure is wrapped by polyvinylpyrrolidone polymer.

[0046] The specific preparation method includes the following steps:

[0047] (1) The reaction system chooses three of chloroauric acid (HuAuCl4·3H2O) or chloroauric acid (MAuCl4·XH2O), ammonium formate (Ammonium Formate) and polyvinylpyrrolidone (PVP) stabilizer as the reactants, and the water phase is the solvent. ; Among them, chloroauric acid or chloroauric acid salt 0.18mmol, polyv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com